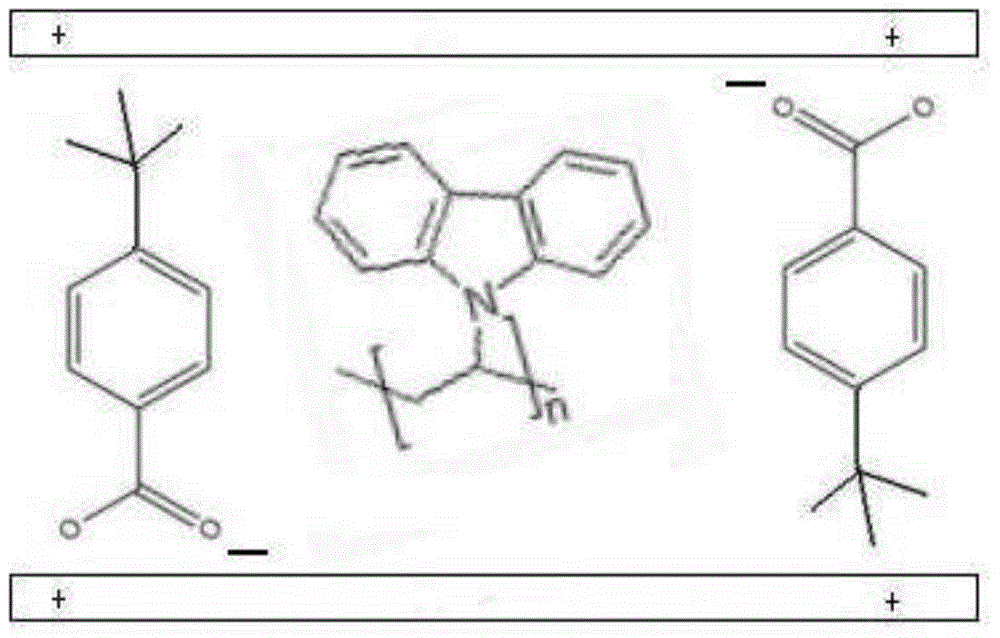

Polyvinyl carbazole intercalated hydrotalcite fluorescent film and preparation method thereof

A technology of polyvinyl carbazole and vinyl carbazole, applied in the field of polyvinyl carbazole intercalated hydrotalcite fluorescent film and its preparation, to achieve the effects of stable intercalation structure, strong corrosion resistance and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

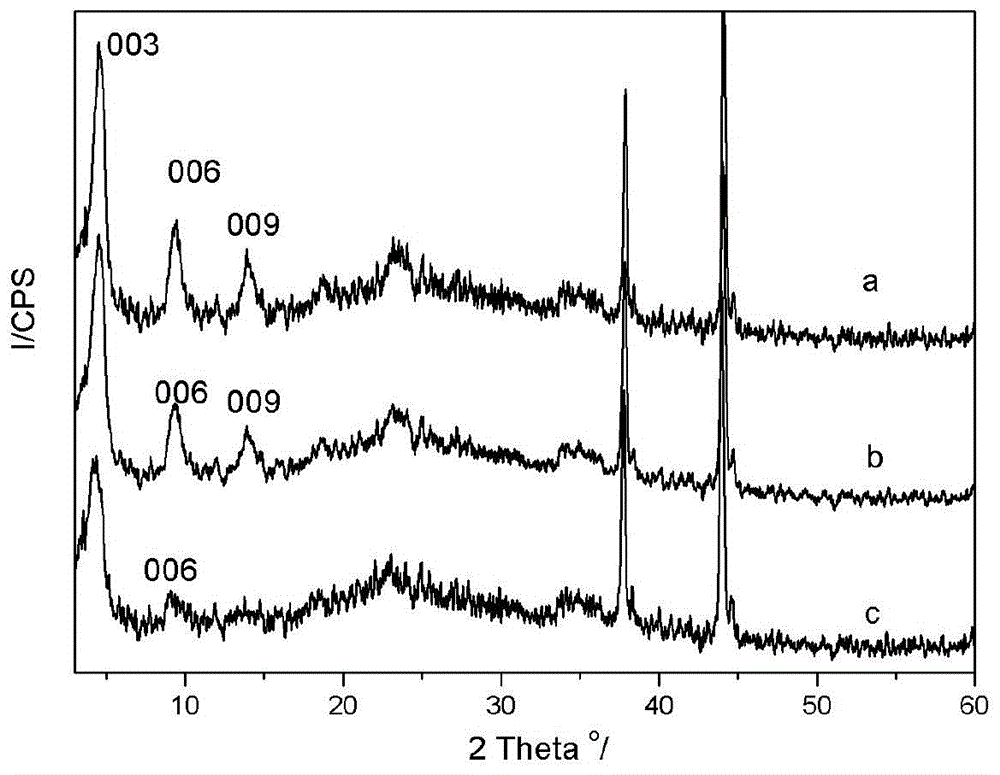

Method used

Image

Examples

Embodiment 1

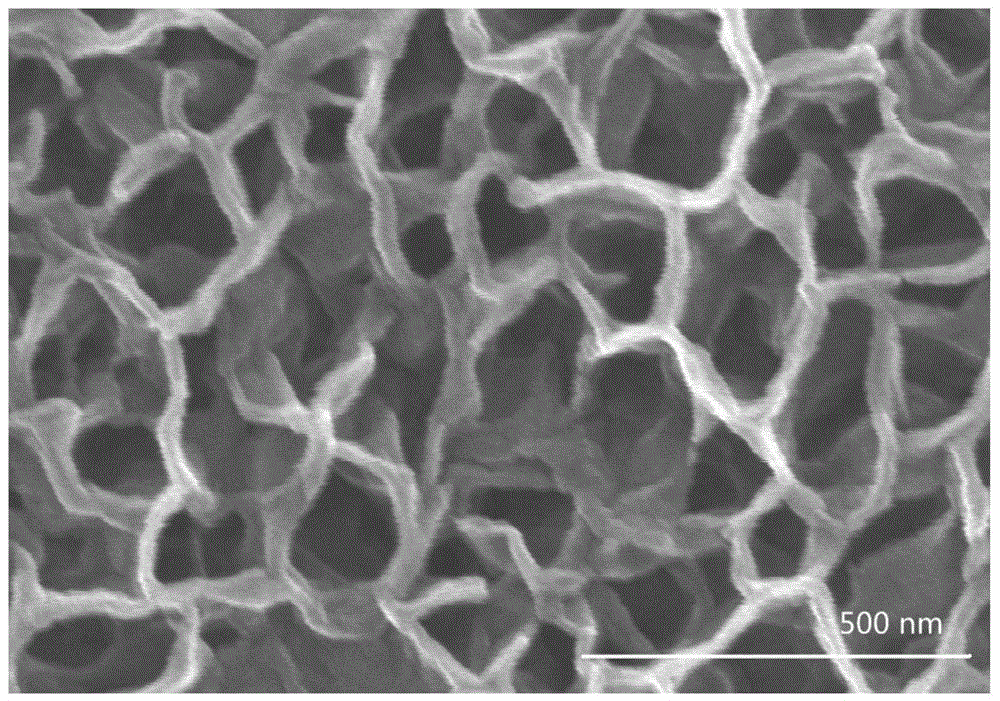

[0031] A. Cut the aluminum sheet into flakes, clean the surface of the aluminum sheet with 0.1mol / L hydrochloric acid solution, ultrasonically clean it in deionized water for 5 minutes (frequency 20KHz), put it into 0.2mol / L NaOH solution for 5 minutes, and use Rinse with deionized water; the cleaned aluminum sheet is used as the anode, and the lead sheet is used as the cathode, with 1.0mol / L H 2 SO 4 The solution is used as electrolyte, constant voltage oxidation, working voltage 12V, oxidation current 1.5A, electrolysis time 1h, electrolysis temperature 20°C; then dry at 25°C for 20h to obtain an aluminum substrate;

[0032] B. Weigh 2.9g Zn(NO 3 ) 2 ·6H 2 O, 0.46g sodium p-tert-butylbenzoate and 4.8g NH 4 NO 3 Dissolve in deionized water to make 100ml reaction synthesis solution, and then use 1% NH 3 ·H 2 O adjusts the pH of the reaction synthesis solution to 6.0; the aluminum substrate (AAO / Al) substrate with a size of 1 cm×2 cm obtained in step A is suspended verti...

Embodiment 2

[0037] A. Cut the aluminum sheet into flakes, clean the surface of the aluminum sheet with 1mol / L hydrochloric acid solution, ultrasonically clean it in deionized water for 2 minutes (frequency 20KHz), soak it in 0.8mol / L NaOH solution for 2 minutes, and wash it with deionized water Rinse with water; use the cleaned aluminum sheet as the anode, and the lead sheet as the cathode, with 1.0mol / L H 2 SO 4 The solution is used as electrolyte, constant voltage oxidation, working voltage 20V, oxidation current 3A, electrolysis time 0.5h, electrolysis temperature 25°C; then dry at 60°C for 10h to obtain an aluminum substrate;

[0038] B. Weigh 2.5g Mg(NO 3 ) 2 ·6H 2 O, 0.46g sodium p-tert-butylbenzoate and 4.8g NH 4 NO 3 Dissolve in deionized water to make 100ml reaction synthesis solution, and then use 1% NH 3 ·H 2 O to adjust the pH of the reaction synthesis solution to 9.0; hang the aluminum substrate (AAO / Al) substrate obtained in step A with a size of 1 cm×2 cm vertically ...

Embodiment 3

[0043] A. Cut the aluminum sheet into flakes, wash the surface of the aluminum sheet with 0.5mol / L hydrochloric acid solution, ultrasonically clean it in deionized water for 3 minutes (frequency 20KHz), put it into 0.5mol / L NaOH solution for 3 minutes, and use Rinse with deionized water; the cleaned aluminum sheet is used as the anode, and the lead sheet is used as the cathode, with 1.0mol / L H 2 SO 4 The solution is used as electrolyte, constant voltage oxidation, working voltage 16V, oxidation current 2A, electrolysis time 0.8h, electrolysis temperature 22°C; then dry at 40°C for 15h to obtain an aluminum substrate;

[0044] B. Weigh 2.0g ZnCl respectively 2 , 0.46g sodium p-tert-butylbenzoate and 4.8g NH 4 Dissolve Cl in deionized water to make 100ml reaction synthesis solution, and then use 1% NH 3 ·H 2 O adjusts the pH of the reaction synthesis solution to 7.0; the aluminum substrate (AAO / Al) substrate with a size of 1 cm × 2 cm obtained in step A is suspended vertical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com