A Two-Stage Cascade Refrigeration Low-Temperature Mixed Refrigerant

A technology of mixed refrigerant and cascade refrigeration, which is applied in the direction of heat exchange materials, chemical instruments and methods, can solve the problems of high potential value of greenhouse effect and poor mutual solubility of lubricating oil, and achieves improved system reliability and enhanced mutual solubility. , the effect of high evaporating pressure and condensing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

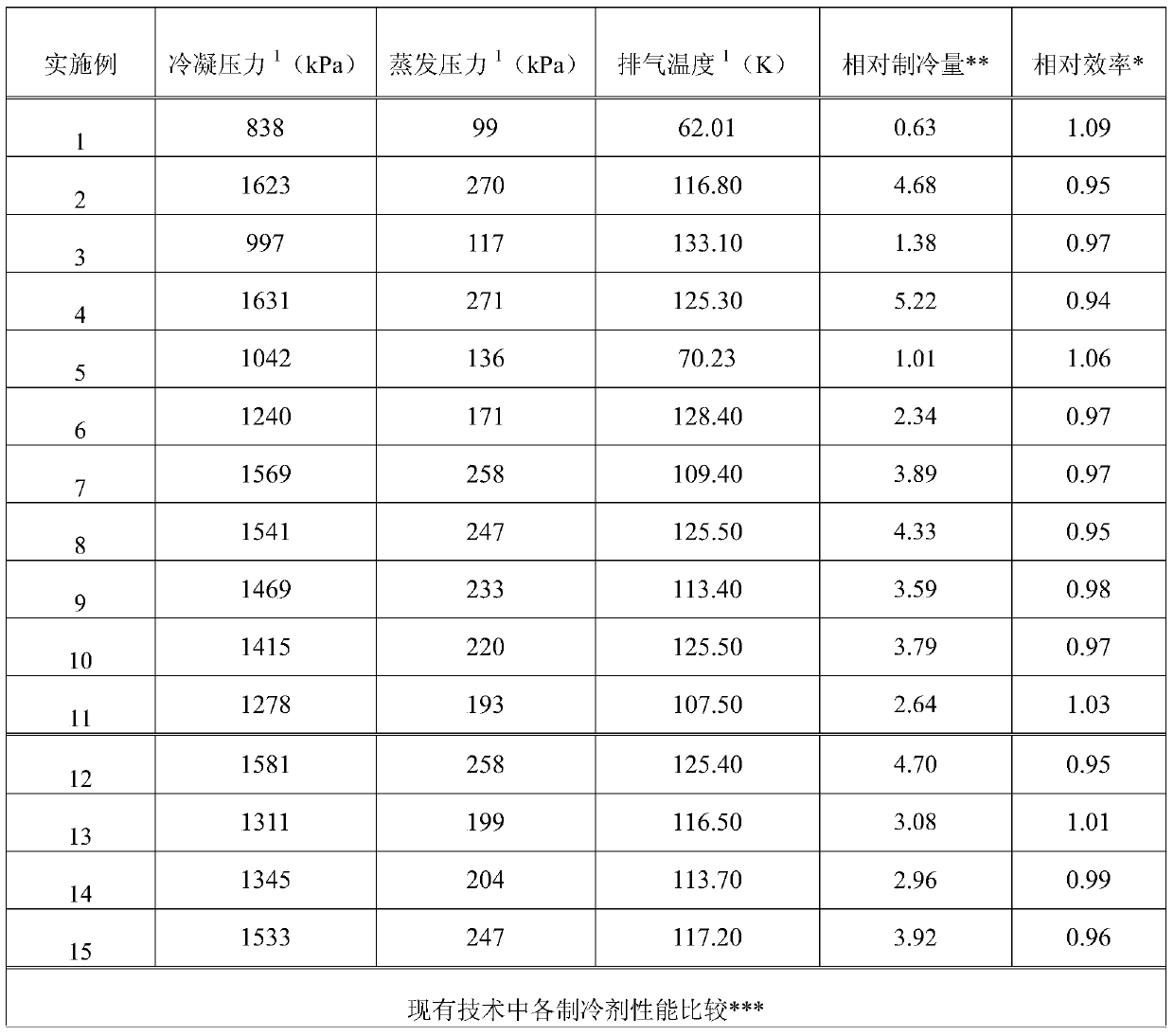

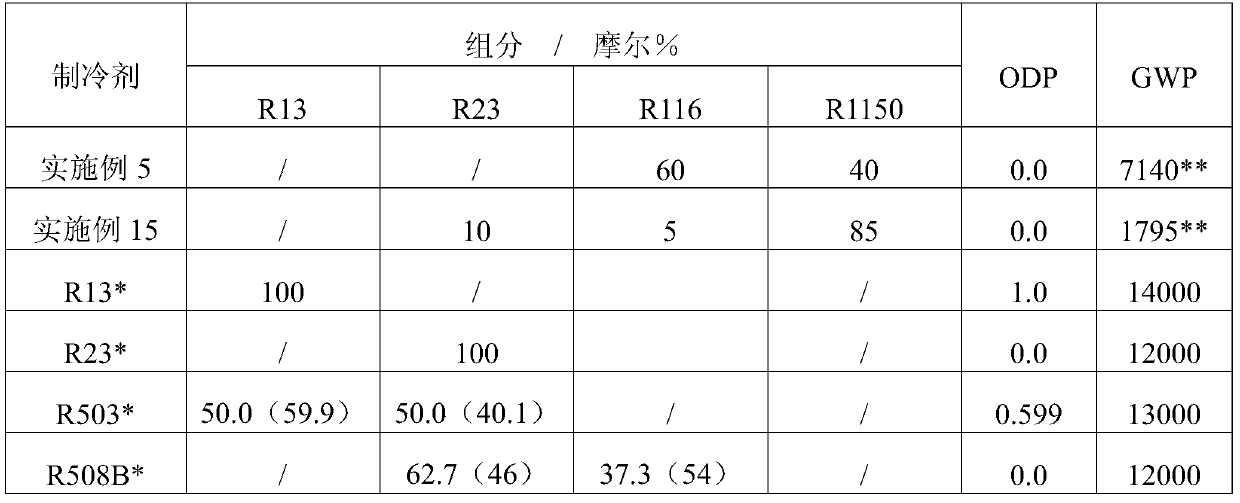

Image

Examples

Embodiment 1

[0025] Example 1: ethylene with a molar concentration of 20% and perfluoroethane with a molar concentration of 80% are physically mixed at room temperature to obtain a two-stage cascade refrigeration low-temperature grade mixed refrigerant.

Embodiment 2

[0026] Example 2: ethylene with a molar concentration of 95% and perfluoroethane with a molar concentration of 5% are physically mixed at room temperature to obtain a low-temperature grade mixed refrigerant for two-stage cascade refrigeration.

Embodiment 3

[0027] Example 3: ethylene with a molar concentration of 20% and trifluoromethane with a molar concentration of 80% were physically mixed at room temperature to obtain a low-temperature grade mixed refrigerant for two-stage cascade refrigeration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com