Conductive ink and application thereof

A conductive ink, selected technology, applied in the direction of ink, applications, household appliances, etc., can solve the problems of unsatisfactory electrical conductivity, overheating of electric heating film, high material cost, etc., and achieve the effect of reducing the risk of overheating and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

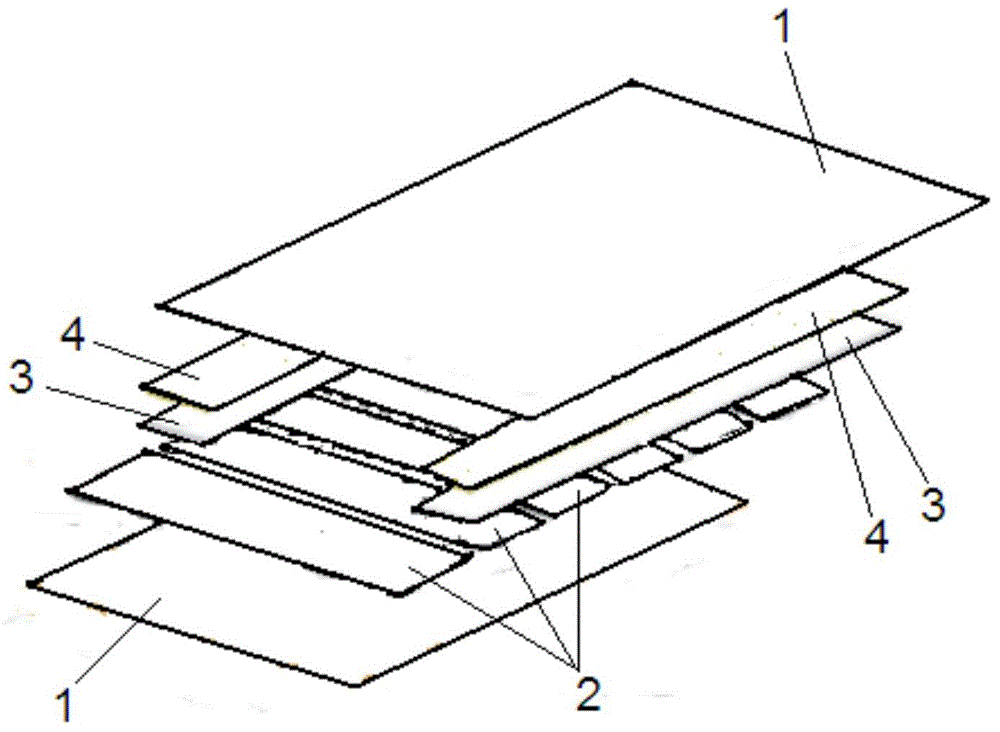

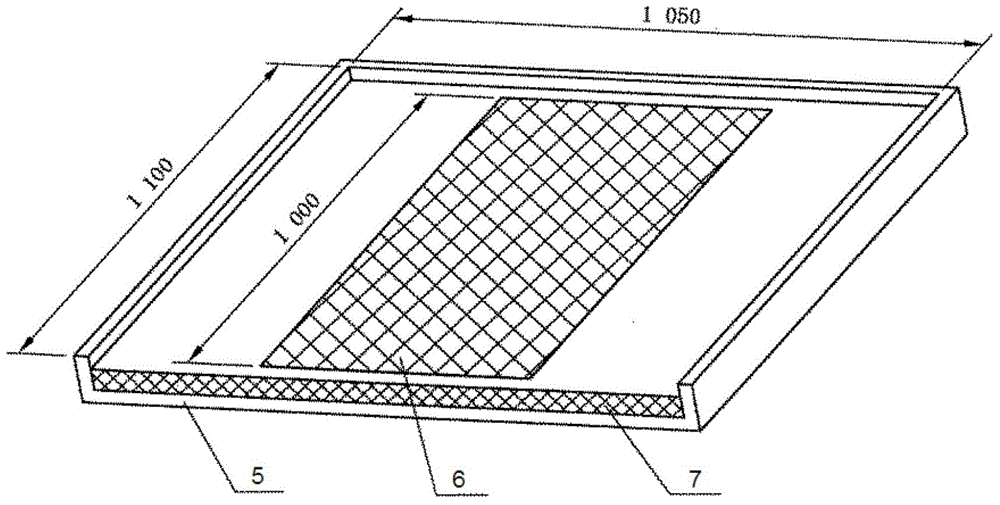

Image

Examples

Embodiment

[0026] Prepare conductive ink of the present invention according to the following steps:

[0027] 1. First, add 50kg of solvent into a 150L stainless steel cylinder, including 30kg of 100# aromatic hydrocarbon solvent and 20kg of ethylene glycol butyl ether, heat to 50°C, and stir for 10 minutes with a disperser. The solution is clear, transparent or light yellow;

[0028] 2. Add 6kg of semi-crystalline polymer ethylene-vinyl acetate copolymer (model Elvax-420, melt index 150, melting point 73°C, provided by DuPont) into the tank, and keep stirring for about 30 minutes until the resin is completely dissolved;

[0029] 3. Add 14kg of amorphous polymer thermoplastic acrylic acid (model B-735, provided by DSM Likang Group Co., Ltd.) to the tank, and keep stirring for about 30 minutes until the resin is completely dissolved;

[0030] 4. Add dispersant (model Disperbyk163, 5.8kg and Disperbyk2001, 4.0kg), defoamer (model Disperbyk057, 0.30kg) and leveling agent (model Disperbyk410,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com