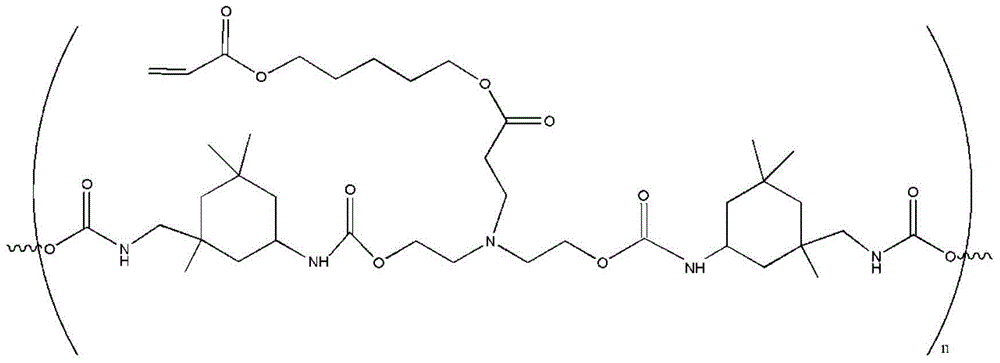

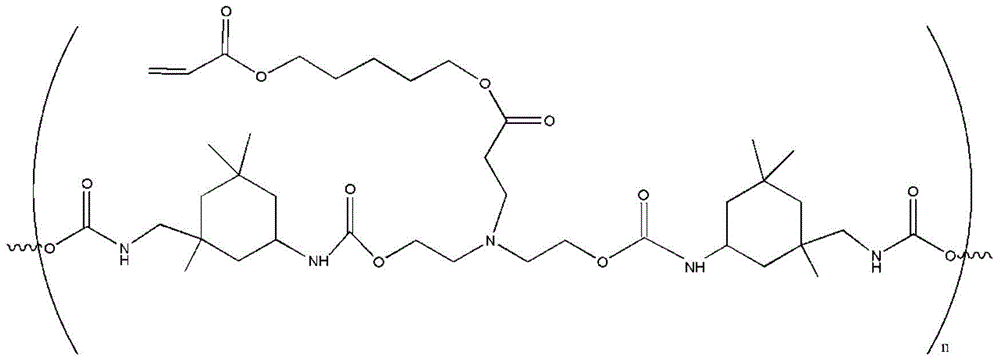

Method of preparing short branch-chain urethane acrylate multifunctional resin with comb-like structure

A technology of polyurethane acrylate and polyurethane resin, which is applied in the field of preparation of comb-shaped multi-branched polyurethane acrylate photopolymerization resin, which can solve the problems of low hardness and low cross-linking density, and achieve high cross-linking density and high conversion rate , the effect of high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Add 1,6-hexanediol diacrylate (HDDA) (0.15mol) and diethanolamine (0.05mol) into a three-necked flask, add 20ml of methanol as a solvent, react at 25°C for 8 hours, and remove methanol by rotary evaporation; Add 15.66 g (0.02 mol) of the prepared product to the flask, add 0.008 g of dibutyltin dilaurate, maintain the reaction temperature at 40 ° C, add 8.88 g (0.04 mol) of isophorone diisocyanate (IPDI), 2 hours later Add 6.26g of polyethylene glycol (hydroxyl value: 268mgKOH / g) and 1.16g of HEA to the reaction system, and raise the temperature to 70°C. After 2 hours of reaction, detect the infrared absorption of isocyanate by infrared;

Embodiment 2

[0022] Add 1,6-hexanediol diacrylate (HDDA) (0.15mol) and diethanolamine (0.05mol) into a three-necked flask, add 20ml of methanol as a solvent, react at 25°C for 8 hours, and remove methanol by rotary evaporation; Add 15.66 g (0.02 mol) of the prepared product to the flask, add 0.016 g of dibutyltin dilaurate, maintain the reaction temperature at 50° C., add 8.88 g (0.04 mol) of isophorone diisocyanate (IPDI), 2 hours later Add 14.7g of ethylene oxide-propylene oxide copolymer (hydroxyl value 114mgKOH / g) and 1.16g of HEA to the reaction system, and raise the temperature to 80°C. After reacting for 2 hours, detect the infrared absorption of isocyanate by infrared;

Embodiment 3

[0024] Add 1,6-hexanediol diacrylate (HDDA) (0.15mol) and diethanolamine (0.05mol) into a three-necked flask, add 20ml of methanol as a solvent, react at 25°C for 8 hours, and remove methanol by rotary evaporation; Add 15.66 g (0.02 mol) of the prepared product to the flask, add 0.016 g of dibutyltin dilaurate, maintain the reaction temperature at 50° C., add 8.88 g (0.04 mol) of isophorone diisocyanate (IPDI), 2 hours later Add 15g of polytetrahydrofuran diol (hydroxyl value: 112mgKOH / g) and 1.16g of HEA to the reaction system, and heat up to 75°C. After reacting for 2 hours, detect the infrared absorption of isocyanate by infrared;

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com