Preparation method of modified phenolic resin and modified phenolic resin prepared by preparation method

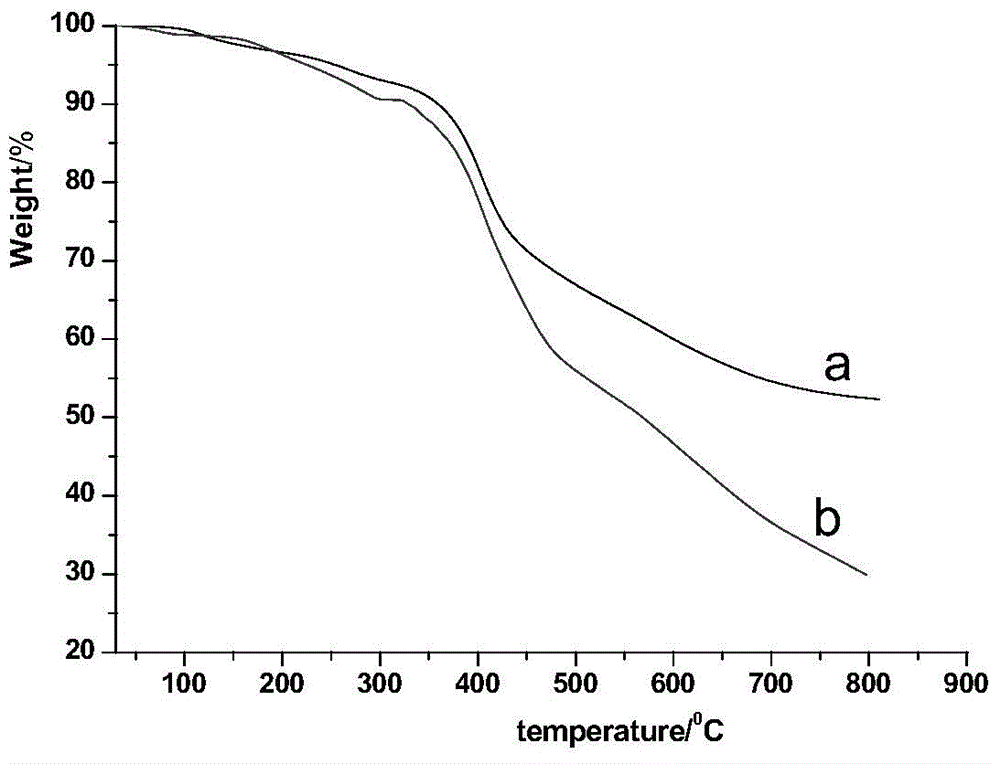

A phenolic resin and modification technology, applied in the field of polymer synthesis and modification, can solve the problems of low boron content of resin, poor reactivity of boric acid, limited heat resistance of resin, etc., and achieve low cost, good environmental protection benefit, good resistance thermal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] Further, the preparation method of modified phenolic resin of the present invention, comprises the steps:

[0024] 1) Add the organoboron compound and excess aldehyde into the reaction kettle, stir evenly, adjust the pH of the reaction solution to 8-12 with alkali, raise the temperature to 80-120°C, and react for 1-4h;

[0025] 2) Add phenol, cardanol and an acidic catalyst to the reaction solution in step 1), adjust the pH to 1-2, and react at a temperature of 90-120°C for 1-6h;

[0026] 3) After dehydration, the modified phenolic resin is obtained.

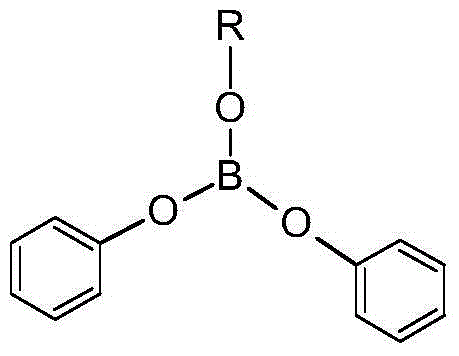

[0027] Further, the organoboron compound is preferably triphenylboronate, 2-aminoethyl diphenylboronate, L-norvalyl diphenylboronate and L-cysteinyl diphenylboronate One or more of phenyl borates. Each triphenyl borate has 9 active sites, which can generate 1-9 substituted triphenyl borates; each diphenyl borate-2-aminoethyl ester has 8 active sites, which can generate 1-8 substituted diphenylboronic acid-2-aminoethyl ...

Embodiment 1

[0038] 1) Mix 35kg of triphenyl borate, 79kg of formaldehyde solution with a mass concentration of 37% and 0.4kg of sodium hydroxide, heat up to 80°C, and react for 1h;

[0039] 2) Add 94kg of phenol, 17kg of cardanol and 1.2kg of oxalic acid to the reaction solution in step 1), and react for 2 hours at a temperature of 90°C;

[0040] 3) After dehydration, the modified phenolic resin is obtained.

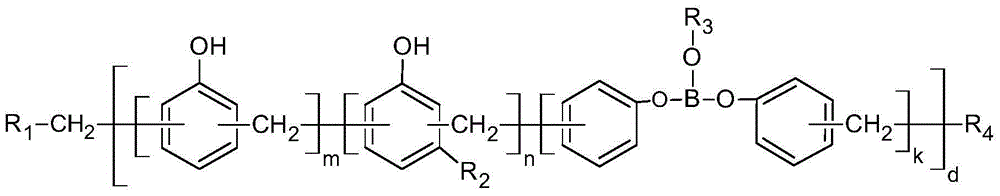

[0041] After testing, the obtained modified phenolic resin is mainly composed of molecules with the following structural formula:

[0042]

[0043] Wherein, m, n, k, and d represent the degree of polymerization, which are integers greater than or equal to 0 that are not necessarily equal, and m, n, and k represent the repeated numbers of phenol groups, cardanol groups, and organoboron segments respectively, d represents the number of repetitions of chain segments that do not necessarily contain the above three groups connected to each other at the same time; R 1 and R 4 It is ...

Embodiment 2

[0045]1) Mix 21kg of 2-aminoethyl diphenyl borate, 80kg of 37% formaldehyde solution and 0.3kg of sodium hydroxide, heat up to 100°C, and react for 1h;

[0046] 2) Add 94kg of phenol, 20kg of cardanol and 0.9kg of hydrochloric acid to the reaction solution in step 1), and react for 3 hours at a temperature of 95°C;

[0047] 3) After dehydration, the modified phenolic resin is obtained.

[0048] After testing, the obtained modified phenolic resin is mainly composed of molecules with the following structural formula:

[0049]

[0050] Wherein, m, n, k, and d represent the degree of polymerization, which are integers greater than or equal to 0 that are not necessarily equal, and m, n, and k represent the repeated numbers of phenol groups, cardanol groups, and organoboron segments respectively, d represents the number of repetitions of chain segments that do not necessarily contain the above three groups connected to each other at the same time; R 1 and R 4 It is the termina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com