Preparation method of metallocene catalyst

A technology of metallocene catalysts and metallocene compounds, which is applied in the field of preparation of metallocene catalysts and can solve the problems of reducing the aging resistance of polymers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

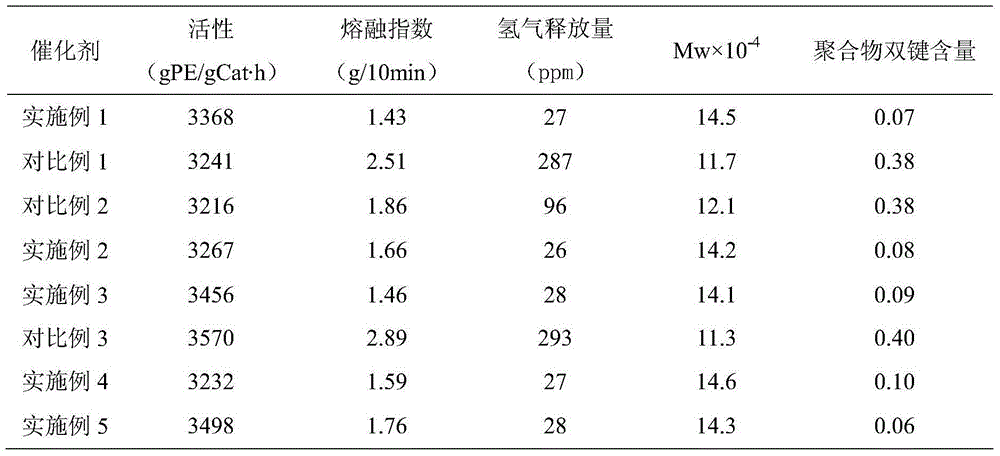

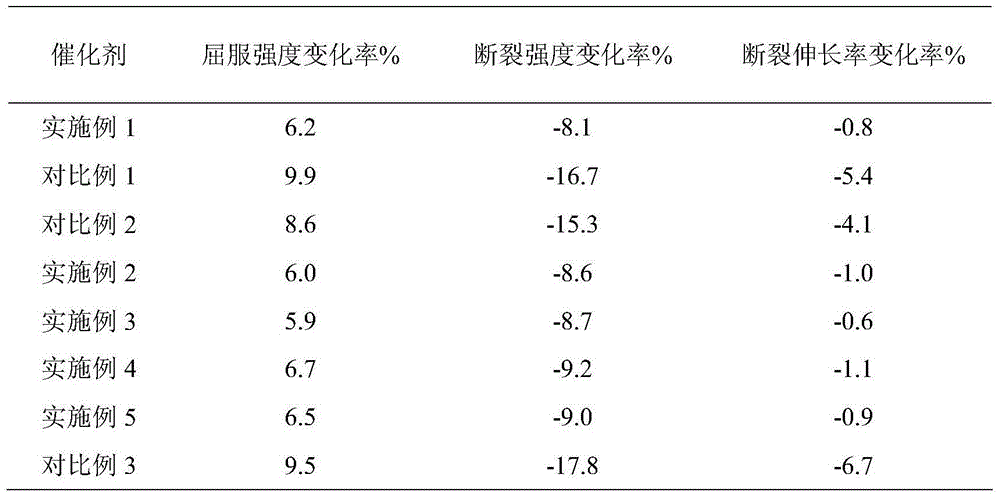

Examples

Embodiment 1

[0034] In 500 mL of tetrahydrofuran, add 4 g of triisobutylaluminum and 0.5 g of nickel acetylacetonate to react at room temperature for 2 hours, then add 5 g of Davison955 silica (commercially available) from Grace Company to continue the reaction at room temperature for 4 hours, and remove the solvent Store in nitrogen gas for later use.

[0035]20 g of 10% by mass percentage of methylaluminoxane toluene solution and 0.15 g of bis(pentamethylcyclopentadienyl) zirconium dichloride were stirred at 50°C for 2 hours to obtain the catalyst mother liquor,

[0036] Then silica gel was added into the mother liquor, the reaction was continued at -10°C for 4 hours, and the solid powder catalyst was obtained after removing the solvent.

Embodiment 2

[0043] In 500mL of tetrahydrofuran, add 7g of triisobutylaluminum and 1g of cobalt acetylacetonate to react for 1 hour at -10°C, then add 15g of Davison955 silicon dioxide from Grace Company and react at room temperature for 6 hours. After removing the solvent, seal the obtained silica gel with nitrogen until use.

[0044] 10 g of 10% by mass percentage of methylaluminoxane toluene solution and 0.05 g of bis(tert-butylcyclopentadienyl) zirconium dichloride were stirred at 70° C. for 4 hours to obtain the catalyst mother liquor,

[0045] Then silica gel was added to the mother liquor, the reaction was continued at -10°C for 6 hours, and the solid powder catalyst was obtained after removing the solvent.

Embodiment 3

[0047] In 500mL of tetrahydrofuran, add 1g of triisobutylaluminum and 0.25g of nickel acetylacetonate to react at 50°C for 3 hours, then add 23g of Davison955 silicon dioxide from Grace Company at 50°C for 4 hours, remove the solvent and seal the obtained silica gel with nitrogen stand-by.

[0048] 100 g of 10% by mass percentage of methylaluminoxane toluene solution and 8 g of bis(n-butylcyclopentadienyl) zirconium dichloride were stirred at 50° C. for 2 hours to obtain the catalyst mother liquor,

[0049] Then silica gel was added into the mother liquor, the reaction was continued at -10°C for 4 hours, and the solid powder catalyst was obtained after removing the solvent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com