A kind of high-weather-resistant thermoplastic polyolefin waterproofing membrane hot-melt pressure-sensitive adhesive and preparation method thereof

A thermoplastic polyolefin and hot-melt pressure-sensitive adhesive technology, applied in the field of pressure-sensitive adhesives, can solve problems such as weather resistance and low-temperature adhesion that cannot meet technical and application requirements, endanger the health of construction workers, and poor adhesion of coils. Achieve excellent stickiness, good pressure sensitivity and good initial tack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

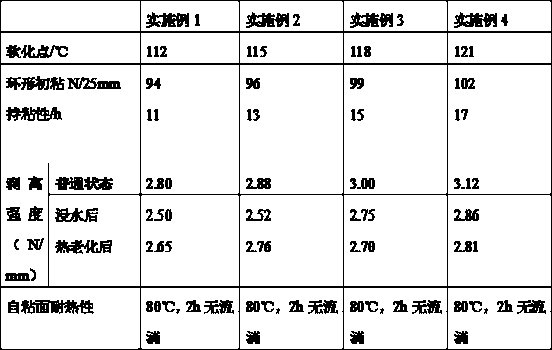

Examples

Embodiment 1

[0031] A high weather resistance thermoplastic polyolefin waterproof membrane hot-melt pressure-sensitive adhesive, composed of the following raw materials: SIS elastomer 20kg, crosslinking agent 2kg, antioxidant 0.5kg, initiator 0.05kg, softener 15kg, viscoelastic modification 5 parts of materials and 35kg of tackifying resin;

[0032] The crosslinking agent is composed of ethoxylated nonylphenol acrylate and hydroxyl-terminated dicaprolactone acrylate in a mass ratio of 1:1; the initiator is tert-butyl hydroperoxide; the viscoelastic modification material is composed of Amorphous olefin copolymer APAO and polyisoprene rubber are composed in a mass ratio of 4:2, the antioxidant is composed of antioxidant 1010 and antioxidant 264 in a mass ratio of 1:1, and the tackifying resin is four Hydrophthalic anhydride modified C5 resin and hydrogenated C9 petroleum resin are composed at a mass ratio of 15:1;

[0033] The tetrahydrophthalic anhydride modified C5 resin is prepared accor...

Embodiment 2

[0036] A high weather resistance thermoplastic polyolefin waterproof membrane hot-melt pressure-sensitive adhesive, composed of the following raw materials: SIS elastomer 40kg, crosslinking agent 8kg, antioxidant 2kg, initiator 0.5kg, softener 30kg, viscoelasticity modified material 7 parts and 60kg of tackifying resin;

[0037] The crosslinking agent is composed of ethoxylated nonylphenol acrylate and hydroxyl-terminated dicaprolactone acrylate in a mass ratio of 1:3; the initiator is tert-butyl hydroperoxide; the viscoelastic modification material is composed of Amorphous olefin copolymer APAO and polyisoprene rubber are composed in a mass ratio of 5:2, the antioxidant is composed of antioxidant 1010 and antioxidant 264 in a mass ratio of 1:1, and the tackifying resin is four Hydrophthalic anhydride modified C5 resin and hydrogenated C9 petroleum resin are composed according to the mass ratio of 5:1;

[0038] The tetrahydrophthalic anhydride modified C5 resin is prepared ac...

Embodiment 3

[0041] A high weather resistance thermoplastic polyolefin waterproof membrane hot-melt pressure-sensitive adhesive, composed of the following raw materials: SIS elastomer 30kg, crosslinking agent 5kg, antioxidant 1kg, initiator 0.2kg, softener 20kg, viscoelasticity modified material , 4 parts and tackifying resin 40kg;

[0042]The crosslinking agent is composed of ethoxylated nonylphenol acrylate and hydroxyl-terminated dicaprolactone acrylate in a mass ratio of 1:2; the initiator is tert-butyl hydroperoxide; the viscoelastic modification material is composed of Amorphous olefin copolymer APAO and polyisoprene rubber are composed in a mass ratio of 4:2, the antioxidant is composed of antioxidant 1010 and antioxidant 264 in a mass ratio of 1:1, and the tackifying resin is four Hydrophthalic anhydride modified C5 resin and hydrogenated C9 petroleum resin are composed at a mass ratio of 10:1;

[0043] The tetrahydrophthalic anhydride modified C5 resin is prepared according to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com