Hybrid diisocyanate polyurethane and preparation method hereof

A technology of diisocyanate and polyurethane, applied in the field of polymer application, can solve the problems of decreased mechanical properties, easy yellowing, cracking, etc., and achieves cost saving, good yellowing resistance, improved adhesion effect and application range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

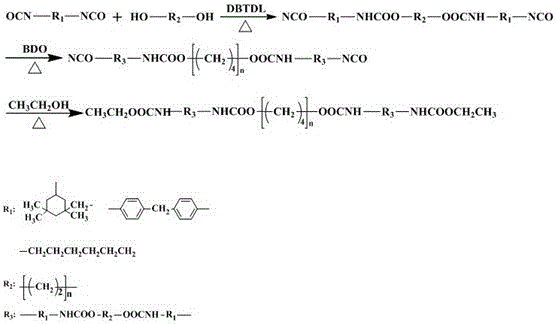

[0028] A preparation method for mixing diisocyanate type polyurethane, comprising the following steps:

[0029] (1) Add the polyol into a split-type three-necked reaction flask equipped with a thermometer, a condensing device, and a mechanical stirrer, dehydrate at 100~105°C for 3~4 hours under vacuum conditions, and cool down to 55~65°C;

[0030] (2) the molar ratio of 9-1:1-9

[0031] Aromatic diisocyanate mixed with aliphatic diisocyanate, the amount of mixed diisocyanate and polyol n (-NCO): n (-OH) is 1:1, dissolve the mixed diisocyanate in dried N,N-dimethylformamide (DMF), prepare a DMF solution with a mass concentration of 30-50%, and add it dropwise to the step ( 1) In the system, stir for 1~1.5h at a temperature of 20~25°C;

[0032] (3) Add 0.01%~0.07% catalyst dibutyltin dilaurate (DBTDL) to the reaction system of step (2), the consumption of catalyst is based on the total mass of mixed diisocyanate and polyol, and heat up to 65~70 ℃ for prepolymerization reacti...

Embodiment 1

[0044] A kind of preparation method of mixed diisocyanate type polyurethane, during preparation, take the split type three-necked reaction flask that reflux condenser, mechanical stirring bar, thermometer are equipped with, prepare according to the following steps:

[0045] (1) Add 0.01 mol of polytetrahydrofuran ether glycol 2000 into a split-type three-necked reaction flask equipped with a thermometer, a condensation device, and a mechanical stirrer, dehydrate under 100°C vacuum for 4 hours, and cool down to 60°C;

[0046] (2) Dissolve 0.0072 mol of mixed diisocyanate in the dry N,N-dimethylformamide ( DMF), prepared into a DMF solution with a mass concentration of 50%, added dropwise to the system in step (1), and stirred at a temperature of 25°C for 1 hour;

[0047] (3) Add 0.03% catalyst dibutyltin dilaurate (DBTDL) to the reaction system of step (2), heat up to 70°C for prepolymerization, and keep warm for 2 hours; obtain a polyurethane prepolymer;

[0048] (4) 0.08mol ...

Embodiment 2

[0052] A kind of preparation method of mixed diisocyanate type polyurethane, during preparation, take the split type three-necked reaction flask that reflux condenser, mechanical stirring bar, thermometer are equipped with, prepare according to the following steps:

[0053] (1) Add 0.02 mol of polytetrahydrofuran ether glycol 2000 into a split-type three-necked reaction flask equipped with a thermometer, a condensation device, and a mechanical stirrer, dehydrate under 100°C vacuum for 4 hours, and cool down to 60°C;

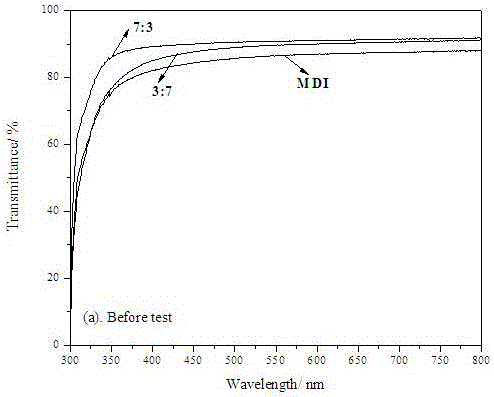

[0054] (2) Dissolve 0.0156 mol of mixed diisocyanate with a molar ratio of toluene diisocyanate (TDI) / hexamethylene diisocyanate (HDI) of 3:7 in dried N,N-dimethylformamide (DMF) , prepared into a DMF solution with a mass concentration of 30%, added dropwise to the system of step (1), and stirred at a temperature of 20°C for 1.5h;

[0055] (3) Add 0.06% catalyst dibutyltin dilaurate (DBTDL) to the reaction system of step (2), heat up to 75° C. for prepolymerizati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com