Complex enzyme preparation for improving starch yield

A compound enzyme preparation and starch technology, which is applied to the preparation methods of peptides, enzymes, lyases, etc., can solve the problems of low corn starch yield, high production cost, and high energy consumption, improve the mechanical separation effect, and reduce the addition cost. , the effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] For the production line of 600 tons / day wet processing corn starch, add the above compound enzyme preparation, the initial addition amount is 0.1‰, and the addition amount is adjusted to 0.03‰ after 24 hours. The adding point of the enzyme preparation is the middle tank of fiber washing, and the feeding is continued for 30 days. In the production process of wet processing corn starch, the transportation of raw materials depends on the transportation of process water. In addition to fresh water for starch washing, other water such as germ washing and fiber washing is process water, and the process water can be recycled.

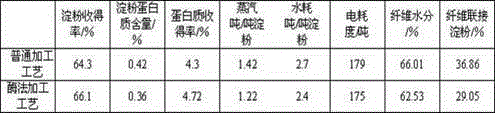

[0032] Table 1 Comparison of relevant data for 30 days of continuous production

[0033]

[0034] Benefit Analysis:

[0035] Starch yield increased by 1.0%, that is, more starch produced = 600 tons / day × 1.0% = 6 tons / day;

[0036] Corn starch is calculated at 3,000 yuan / ton, and direct economic benefits = 6 tons / day × 3,000 yuan / ton = 18,000 yua...

Embodiment 2

[0042]For the production line of 600 tons / day wet processing corn starch, add the above compound enzyme preparation, the initial addition amount is 0.15‰, and the addition amount is adjusted to 0.08‰ after 24 hours. The adding point of the enzyme preparation is the middle tank of fiber washing, and the feeding is continued for 7 days.

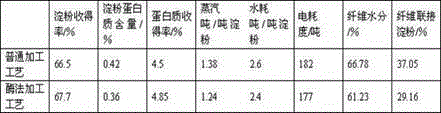

[0043] Table 2 Comparison of relevant data for 7 days of continuous production

[0044]

Embodiment 3

[0046] For the production line of 300 tons / day wet processing corn starch, add the above compound enzyme preparation, the initial addition amount is 0.15‰, and the addition amount is adjusted to 0.06‰ after 24 hours. The adding point of the enzyme preparation is the middle tank of fiber washing, and the feeding is continued for 7 days.

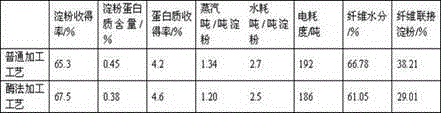

[0047] Table 3 Comparison of relevant data for 7 days of continuous production

[0048]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com