Anticaking agent for powdery emulsion explosive and preparation method thereof

A technology of powder emulsion explosive and anti-caking agent, which is applied in non-explosive/non-thermal agent components, explosives, offensive equipment, etc. The effect of tight bonding, complete explosion reaction, preventing recrystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Add 180kg of 6mol / L sulfuric acid solution to the reaction kettle, raise the temperature to 90°C, and gradually add 400kg of 2mol / L sodium silicate solution under stirring. After all the sodium silicate solution is added, continue to stir and react for 28 minutes, then stop stirring. Let stand for 40 minutes.

[0020] Preheat the spray drying system for about 30 minutes. After the outlet temperature of the blower reaches 135-145°C, stir and beat the reacted slurry, start the screw pump, and control the delivery pressure of the screw pump within 0.45MPa. Under temperature conditions, the slurry is transported to the tower for atomization, dehydrated and dried to make powder, and packed into bags of anti-caking agent of 10-25kg per bag.

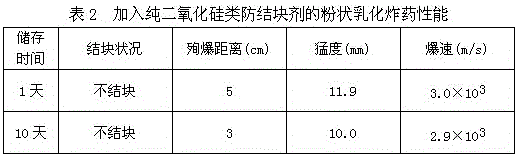

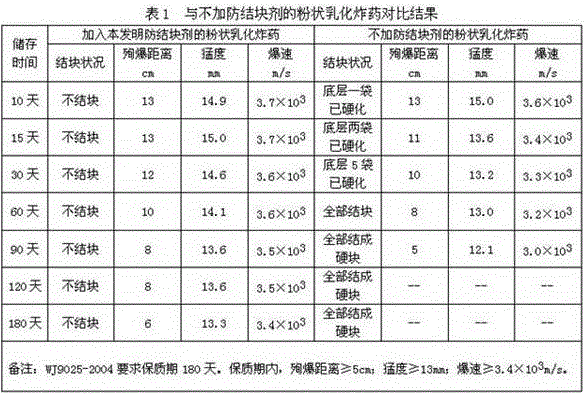

[0021] Take 1.5kg of anti-caking agent and add it to 300kg of powdered emulsion explosive, pack it into a large bag of 40kg / bag, stack it for storage, and it will not agglomerate after 6 months. 3 m / s.

Embodiment 2

[0023] Add 172kg of 6mol / L sulfuric acid solution to the reaction kettle, raise the temperature to 95°C, gradually add 390kg of 2mol / L sodium silicate solution under stirring, after all the sodium silicate solution is added, continue to stir and react for 30 minutes, stop stirring, Let stand for 50 minutes.

[0024] Preheat the spray drying system for about 30 minutes. After the outlet temperature of the blower reaches 135-145°C, stir and beat the reacted slurry, start the screw pump, and control the delivery pressure of the screw pump within 0.3MPa. Under temperature conditions, the slurry is transported to the tower for atomization, dehydrated and dried to make powder, and packed into bags of anti-caking agent of 10-25kg per bag.

[0025] Take 3kg of anti-caking agent and add it to 300kg of powdered emulsion explosive, pack it into a large bag of 40kg / bag, stack it for storage, and it will not agglomerate after 6 months. 3 m / s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com