Hollow glass

A glass and hollow technology, applied in the field of insulating glass, can solve the problems of reducing heat insulation, easy to accumulate dust, difficult to clean, etc., and achieve the effects of avoiding safety accidents, improving energy saving performance, and increasing heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

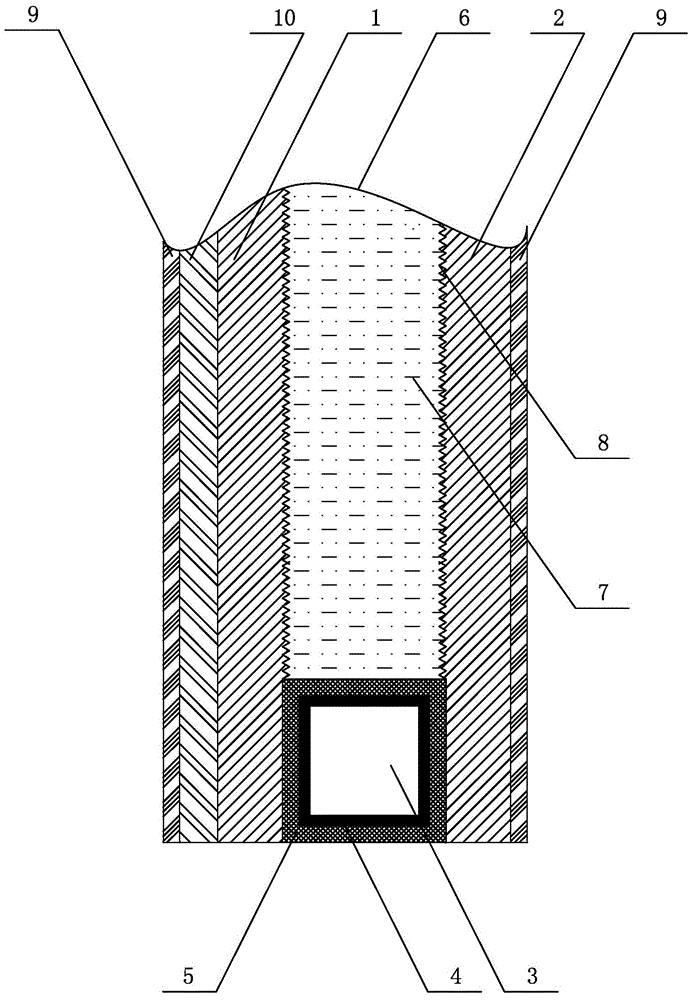

[0020] Such as figure 1 As shown, a specific embodiment of the invention is proposed, an insulating glass comprising an outer layer of glass 1, an inner layer of glass 2 and a spacer frame 3 between the two layers of glass. The spacer 3 is arranged on the periphery of the two layers of glass and separates the two layers. Glass; the gap between the spacer frame 3 and the two layers of glass is filled with a butyl rubber layer 4, the outer surface of the butyl rubber layer 4 is covered with a polysulfide layer 5; the spacer frame 3 and the two layers of glass 1 The cavity 6 formed between is filled with dry inert gas 7.

[0021] The spacer frame 3 is a thermoplastic spacer frame with a hollow structure. In this embodiment, it is preferred that the thermoplastic spacer frame 3 is made of a mixture of butyl rubber, polyisobutylene, and softener materials to realize an ideal warm edge technology.

[0022] The surfaces of the two layers of glass facing the cavity 6 are continuously prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com