Two-stage catalytic oxidation wastewater treatment system

A wastewater treatment system, catalytic oxidation technology, applied in the direction of oxidized water/sewage treatment, water/sewage treatment, neutralized water/sewage treatment, etc. Reduce energy consumption and other issues, achieve the effect of improving effluent water quality, reducing the dosage of chemicals, and reducing the concentration of organic matter in effluent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

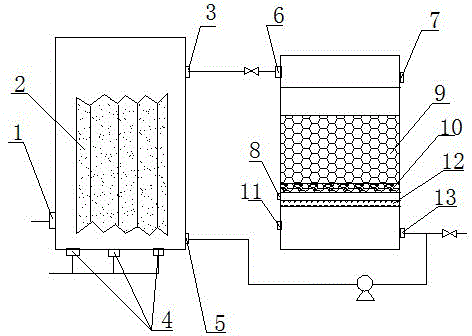

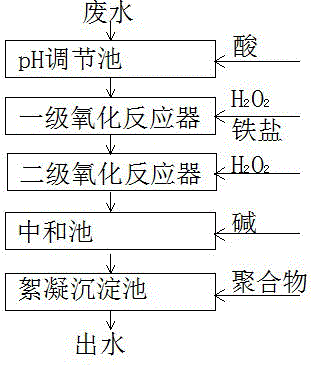

[0024] A two-stage catalytic oxidation wastewater treatment system, which is connected to a PH adjustment tank, an oxidation reactor, a neutralization tank, a flocculation sedimentation tank through a water supply pipeline, and the oxidation reactor includes a primary oxidation reactor and a secondary oxidation reactor, and the primary oxidation reaction The water outlet 1 of the device is connected to the water inlet 6 of the secondary oxidation reactor through a pipeline, the primary oxidation reactor is a homogeneous oxidation reactor, and the secondary oxidation reactor is a fixed bed oxidation reactor;

[0025] The bottom of the primary oxidation reactor is provided with an air inlet 4, the lower part is provided with a water inlet 1, and the upper part is provided with a water outlet 3, and the water outlet 3 is connected back to the lower part of the primary oxidation reactor through a pipeline, and is set as a return water inlet 5; The upper part of the oxidation reacto...

Embodiment 2

[0027] A two-stage catalytic oxidation wastewater treatment system, which is connected to a PH adjustment tank, an oxidation reactor, a neutralization tank, a flocculation sedimentation tank through a water supply pipeline, and the oxidation reactor includes a primary oxidation reactor and a secondary oxidation reactor, and the primary oxidation reaction The water outlet 1 of the device is connected to the water inlet 6 of the secondary oxidation reactor through a pipeline, the primary oxidation reactor is a homogeneous oxidation reactor, and the secondary oxidation reactor is a fixed bed oxidation reactor;

[0028] The bottom of the primary oxidation reactor is provided with an air inlet 4, the lower part is provided with a water inlet 1, and the upper part is provided with a water outlet 3, and the water outlet 3 is connected back to the lower part of the primary oxidation reactor through a pipeline, and is set as a return water inlet 5; The upper part of the oxidation reacto...

Embodiment 3

[0032] A two-stage catalytic oxidation wastewater treatment system, which is connected to a PH adjustment tank, an oxidation reactor, a neutralization tank, a flocculation sedimentation tank through a water supply pipeline, and the oxidation reactor includes a primary oxidation reactor and a secondary oxidation reactor, and the primary oxidation reaction The water outlet 1 of the device is connected to the water inlet 6 of the secondary oxidation reactor through a pipeline, the primary oxidation reactor is a homogeneous oxidation reactor, and the secondary oxidation reactor is a fixed bed oxidation reactor;

[0033] The bottom of the primary oxidation reactor is provided with an air inlet 4, the lower part is provided with a water inlet 1, and the upper part is provided with a water outlet 3, and the water outlet 3 is connected back to the lower part of the primary oxidation reactor through a pipeline, and is set as a return water inlet 5; The upper part of the oxidation reacto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com