Vertical continuous flow phosphorus removing device and method

A vertical and biological phosphorus removal technology, applied in the field of sewage treatment, can solve the problems of inability to achieve the best effect of nitrogen and phosphorus removal, affecting the phosphorus removal effect, and difficult phosphorus removal load, etc., and achieve high application value and development potential. , The effect of short precipitation time and large phosphorus removal load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] specific implementation plan

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings.

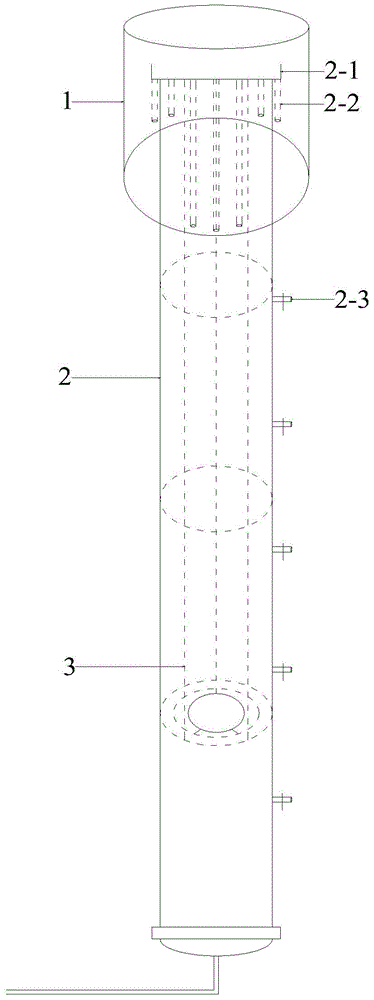

[0046] refer to figure 1 , figure 2 and image 3 , The vertical continuous flow dephosphorization device of the present invention comprises: 1-sedimentation tank, 1-1-water outlet, 1-2-sludge water collection container, 1-3-sludge discharge port, 1-4-sludge particle return port; 2- reactor, 2-1- overflow weir, 2-2- diversion pipe, 2-3- sampling port, 2-4- return sludge inlet, 2-5- water inlet; 3- adjustable aeration Device, 3-1-support frame unit, 3-2-ring baffle, 3-3-aeration ring.

[0047] The specific operation mode is described as follows:

[0048] (1) Fill the reactor with polyphosphorus granular sludge, and the sludge concentration is between 3000 and 5000 mg / L.

[0049] (2) During operation, first adjust the aeration ring 3-3 in the adjustable aeration device 3 to a suitable position (adjust within the dista...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com