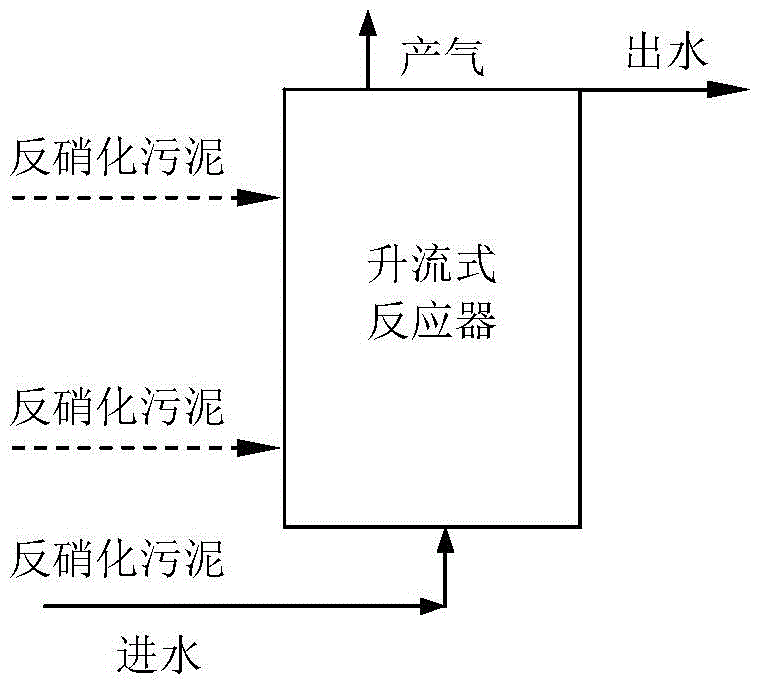

Method for rapidly starting up-flow reactor through denitrification

A rapid start-up and reactor technology, applied in anaerobic digestion treatment and other directions, can solve the problems of long start-up period, loss, and no granular sludge, and achieve the effect of eliminating sludge floating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0114] Use the dehydrated residual sludge of the municipal sewage treatment plant as the seed sludge of denitrification sludge, domesticate it into denitrification sludge through the wastewater containing nitrite nitrogen, and start the upflow reactor.

[0115] The volume of the stirred tank is 1 / 3 times the volume of the upflow reactor. Add the influent water used for acclimating the seed mud into the stirring tank, the pH is 6.5; turn on the stirrer, and the rated stirring power is 40W / m 3 , the stirring speed is set to 500 rpm; add sodium nitrite to the stirring tank; add the suspension containing ferric hydroxide; add the remaining sludge after dehydration in the municipal sewage treatment plant, and measure its moisture content in the range of 78-85 %, its addition method is: mix the residual sludge after dehydration that has been stored for no more than 3 days into the influent water used for the domesticated seed sludge, and pump it into the mixing tank through the slud...

Embodiment 2

[0119] The mixture of digester sludge of municipal sewage treatment plant and sludge discharged from anaerobic reactor is used as denitrification sludge seed sludge, which is domesticated into denitrification sludge by wastewater containing nitrate nitrogen, and the upflow reactor is started.

[0120] The volume of the stirred tank is twice the volume of the upflow reactor. Add the influent water used for the domestication seed mud into the stirring tank; add 8wt% sodium nitrate solution to the stirring tank; turn on the stirrer, and the stirring power is 30W / m 3 , the stirring speed is 100 rev / min; add the liquid mixture containing methanol and ethanol to the stirring tank; add the wastewater containing ferric chloride; add sodium bicarbonate solution to adjust its pH to 6.5; add the digester sludge of the municipal sewage treatment plant The mixture with the sludge discharged from the anaerobic reactor; after the mud water in the stirring tank is evenly mixed, the total unfi...

Embodiment 3

[0124] Use the mixture of residual sludge from municipal sewage treatment plants and sludge from aeration tanks of industrial wastewater treatment plants as denitrification sludge seed sludge to domesticate denitrification sludge through wastewater containing nitrate nitrogen and nitrite nitrogen, and start the upflow reactor .

[0125] The volume of the stirring tank is 3 times the volume of the upflow reactor, and the feed water used for domestication seed mud is added to the stirring tank; the stirrer is turned on, and the stirring power is 30W / m 3 , the stirring speed is 20 rpm; add a solid mixture containing sodium formate and sodium ethoxide to the mixing tank; add ferrous sulfate powder, add sodium carbonate solution to adjust its pH to 8; add residual sludge and industrial wastewater from municipal sewage treatment plants Sludge in the aeration tank of the treatment plant; after the mud and water in the mixing tank are evenly mixed, the total non-filterable residue in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com