A method for preparing rice husk-based activated carbon by using solution leaching and deashing

A technology of rice husk carbon and activated carbon, which is applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of low specific surface area of activated carbon and underdeveloped pore structure, and achieve excellent adsorption performance, good adsorption, and corrosion resistance. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

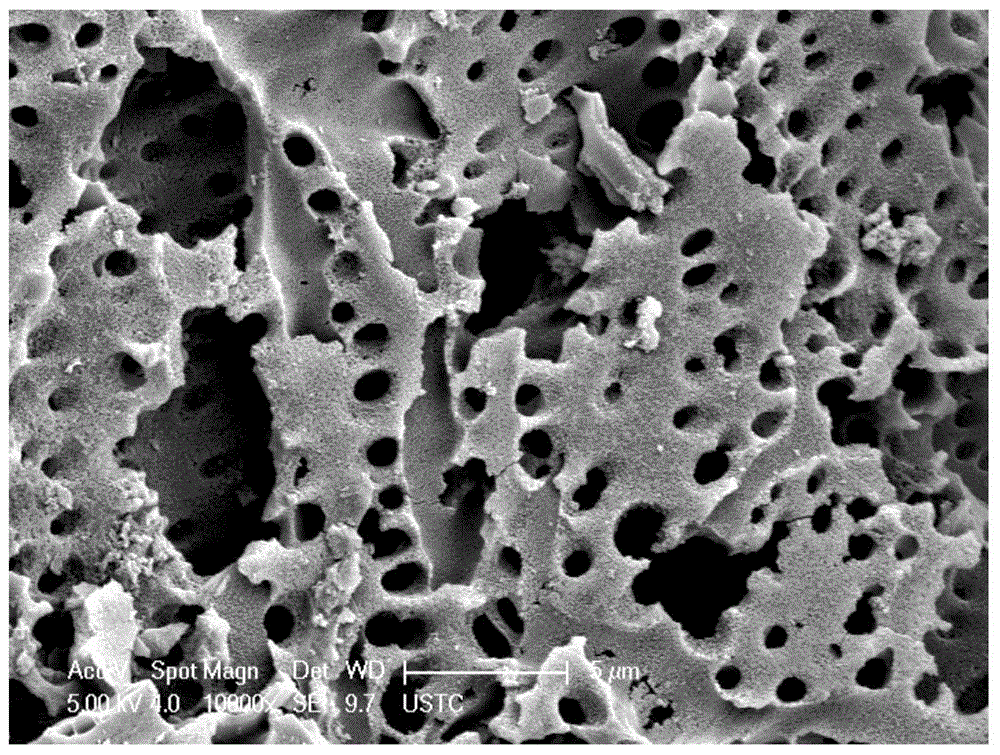

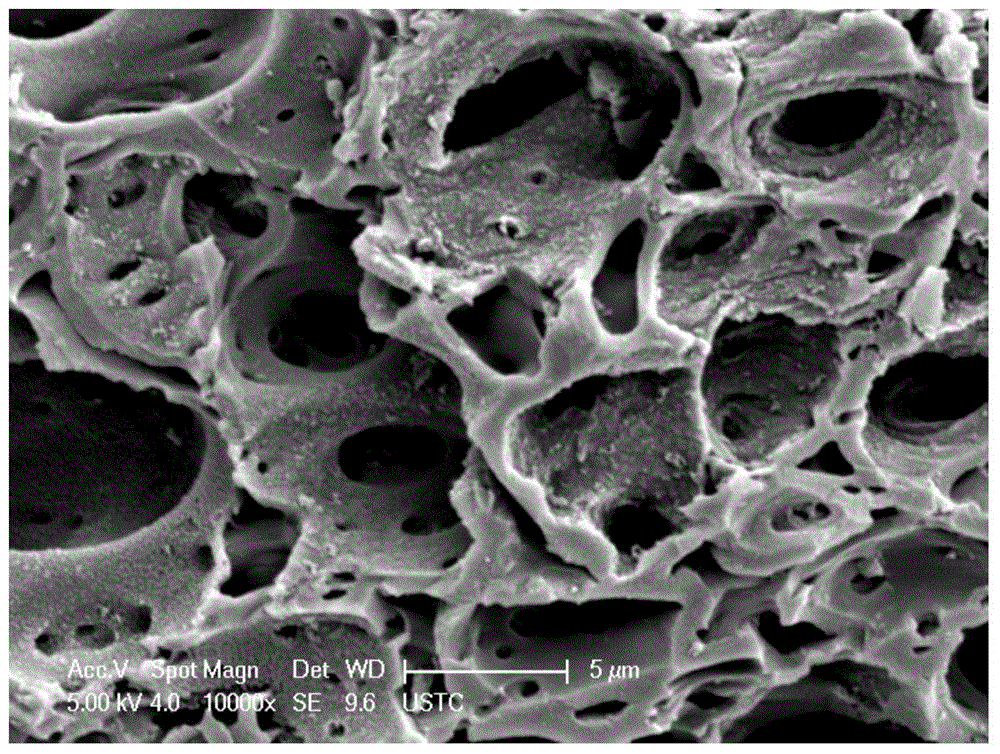

Image

Examples

Embodiment 1

[0026] Rice husk char is a by-product of pyrolysis of rice husk to produce bio-oil. The specific preparation process is as follows: the rice husk is sent into the moving bed pyrolysis reactor through the screw feeder, heated to 510°C at a speed of 480°C / s, the residence time of the rice husk in the pyrolysis reactor is 4s, and then passed through The cyclone separator separates and collects rice husk charcoal.

[0027] (1)CO 2 Activation stage: sieve rice husk charcoal, select particles with a particle size between 40 and 60 meshes; weigh 5g of rice husk charcoal powder obtained by sieving, put it in a quartz boat, and then place the quartz boat in a programmed temperature rise furnace within; in N 2 Heating to 900°C under protection, the heating rate is 10°C / min, N 2 The flow rate is 500mL / min; change to CO 2 , flow rate is 800mL / min, activation 1h; in N 2 Cool to room temperature under protection, N 2 The flow rate is 500mL / min;

[0028] (2) Solution immersion stage: ...

Embodiment 2

[0031] The rice husk charcoal used is the same as that used in Example 1.

[0032] (1)CO 2 Activation stage: sieve rice husk charcoal, select particles with a particle size between 40 and 60 meshes; weigh 5g of rice husk charcoal powder obtained by sieving, put it in a quartz boat, and then place the quartz boat in a programmed temperature rise furnace within; in N 2 Heating to 900°C under protection, the heating rate is 10°C / min, N 2 The flow rate is 500mL / min; change to CO 2 , flow rate is 800mL / min, activation 1h; in N 2 Cool to room temperature under protection, N 2 The flow rate is 500mL / min;

[0033] (2) Solution immersion stage: weigh CO 2 2 g of the activated sample was placed in a round bottom flask, and 4 mol / L of K was added 2 CO 3 Solution 20mL, under reflux conditions, boiling under normal pressure for 2h; stop heating, filter after cooling to room temperature, wash the solid precipitate repeatedly with hot distilled water until the washing liquid is neutr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com