Intelligent bamboo-shaped releasing mechanism made of shape memory polymer composite material

A memory polymer and composite material technology, applied in motor vehicles, space navigation equipment, space navigation equipment, etc., can solve the problems of impact, atmospheric environmental pollution, explosion debris damage to surrounding structures and equipment, etc., to reduce weight , The effect of stable release process and few control links of system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

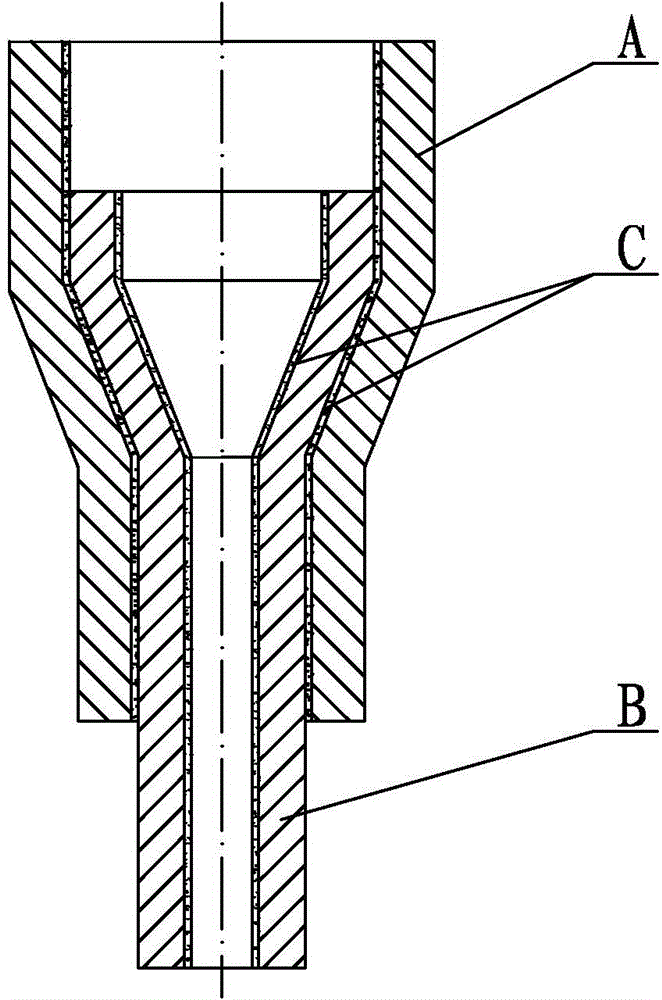

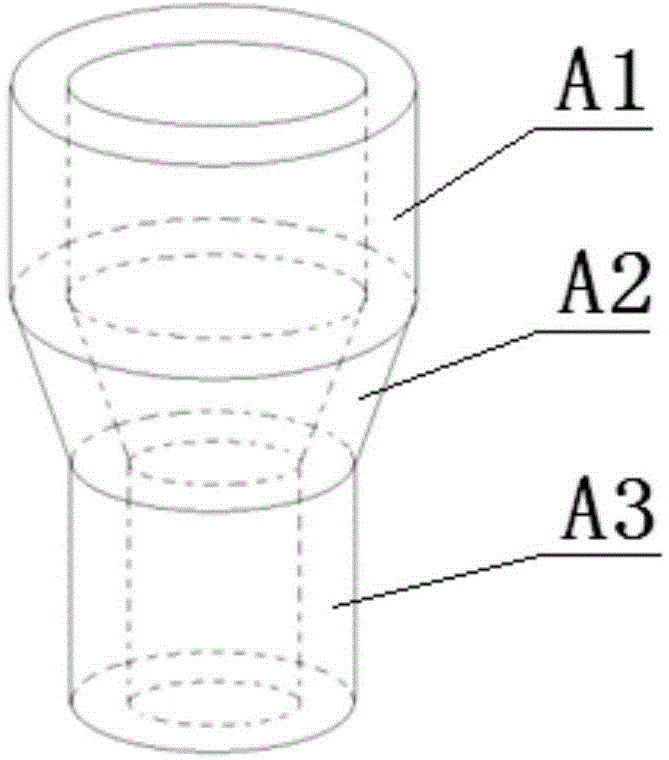

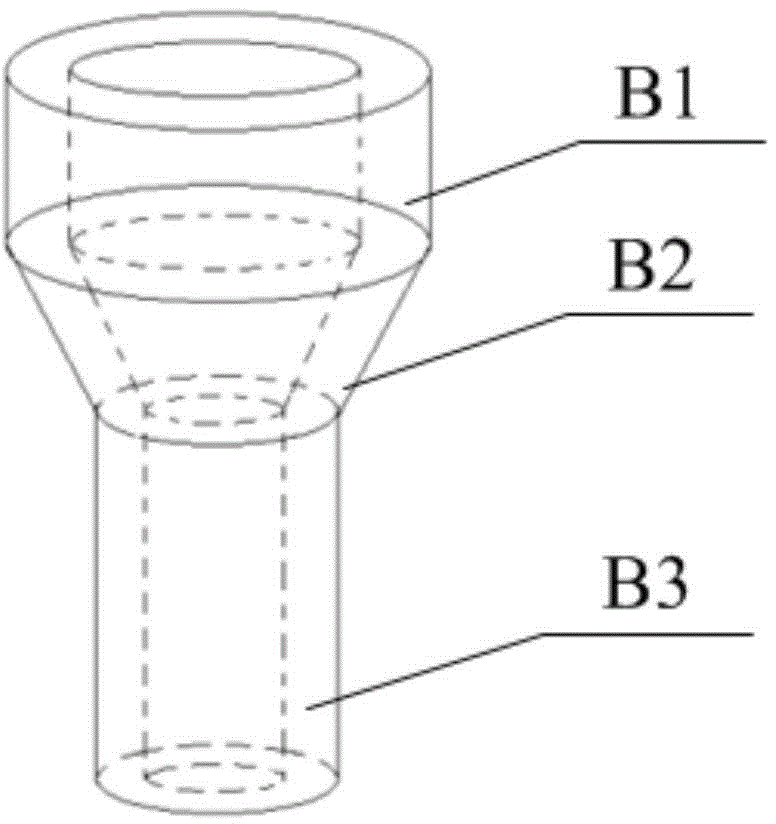

[0015] Specific implementation mode one: combine Figure 1 ~ Figure 3 Describe this embodiment. This embodiment includes an inner sleeve driver B, an outer sleeve booster A and an electrothermal film C. The inner sleeve driver B from top to bottom is the inner upper straight section B1, the inner cone section B2 and the inner The lower straight barrel section B3, the diameter of the inner lower straight barrel section B3 is smaller than the diameter of the inner upper straight barrel section B1, and the outer sleeve strengthener A from top to bottom is the outer upper straight barrel section A1, the outer cone section A2 and the outer lower straight barrel section A3 , the diameter of the outer lower straight section A3 is smaller than the diameter of the outer upper straight section A1, the outer sleeve booster A is set on the inner sleeve driver B, the inner upper straight section B1 is located in the outer upper straight section A1, and the inner cone section B2 Located in ...

specific Embodiment approach 2

[0017] Specific implementation mode two: combination Figure 1 ~ Figure 3 To describe this embodiment, the inner diameter of the lower outer straight section A3 in this embodiment is smaller than the outer diameter of the upper inner straight section B1. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0018] Specific implementation mode three: combined diagram Figure 1 ~ Figure 3 Describe this embodiment, the shape memory polymer composite material of this embodiment is styrene type shape memory polymer, epoxy resin type memory polymer, cyanate type shape memory polymer, shape memory polyester, shape memory benzene Ethylene-butadiene polymer or shape memory polynorbornene. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com