Heating method of fuel oil

A heating method and fuel oil technology, applied in fuel heat treatment devices, liquid fuel feeders, charging systems, etc., can solve problems such as becoming a vacuum, increasing the viscosity of fuel oil, and being difficult to transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

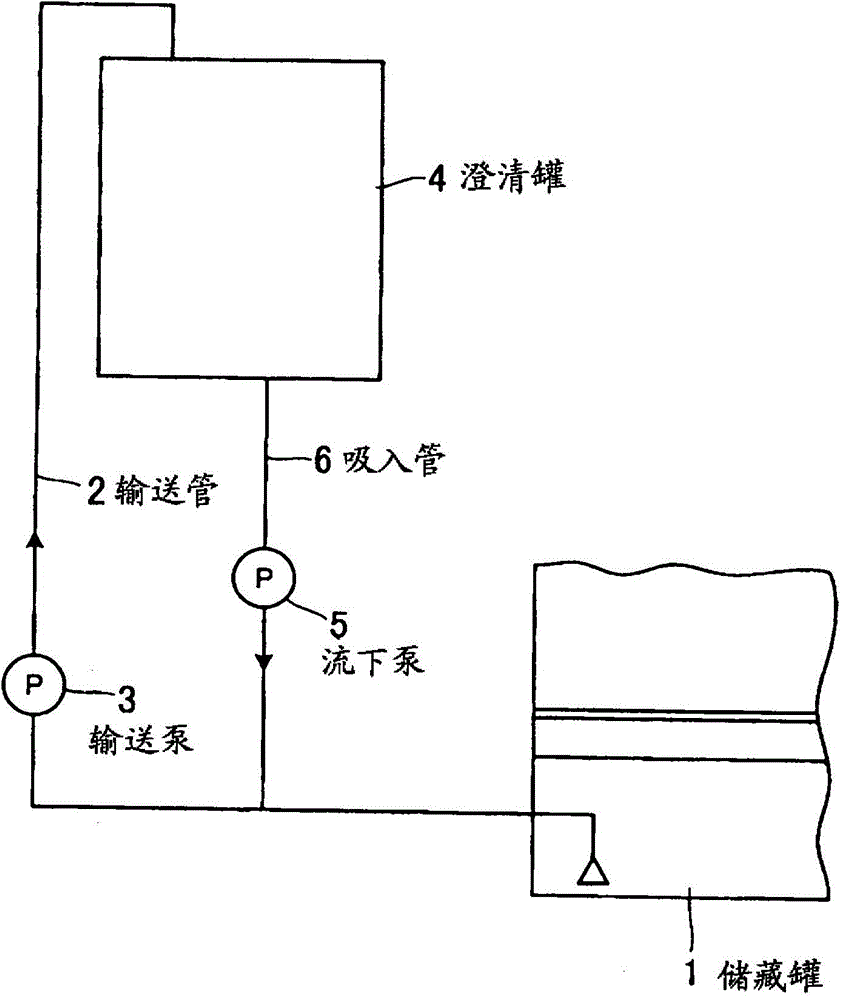

[0022] figure 1 It is a flow chart showing the heating system of the fuel oil in the storage tank. First, a desired amount of fuel oil such as C-heavy oil is charged into the storage tank 1, and at the same time, a fuel oil (not shown) built in the clarification tank 4 is used. The heated device heats the fuel oil in the clarification tank 4 , and the heated fuel oil flows down into the storage tank 1 through the suction pipe 6 by the operation of the downflow pump 5 . In the storage tank 1, the stored fuel oil and the heated fuel oil flowing down are partially mixed and partially heated to 36°C to 40°C. This heating reduces the viscosity of the fuel oil.

[0023] Next, the partially heated fuel oil in the storage tank 1 passes through the delivery pipe 2 and is delivered to the clarification tank 4 in the direction of the arrow by the operation of the delivery pump 3 . The fuel oil delivered to the clarification tank 4 is heated to a desired temperature by a heating device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com