Vertical foil feeding and collecting integrated hot stamping machine

A hot stamping machine and foil feeding technology, applied in printing machines, rotary printing machines, printing and other directions, can solve the problems of inconvenient recycling, waste foil pollution, affecting the health of operators, etc., and achieve easy recycling, short transmission routes, The effect of reducing the chance of stretch deformation and lateral drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

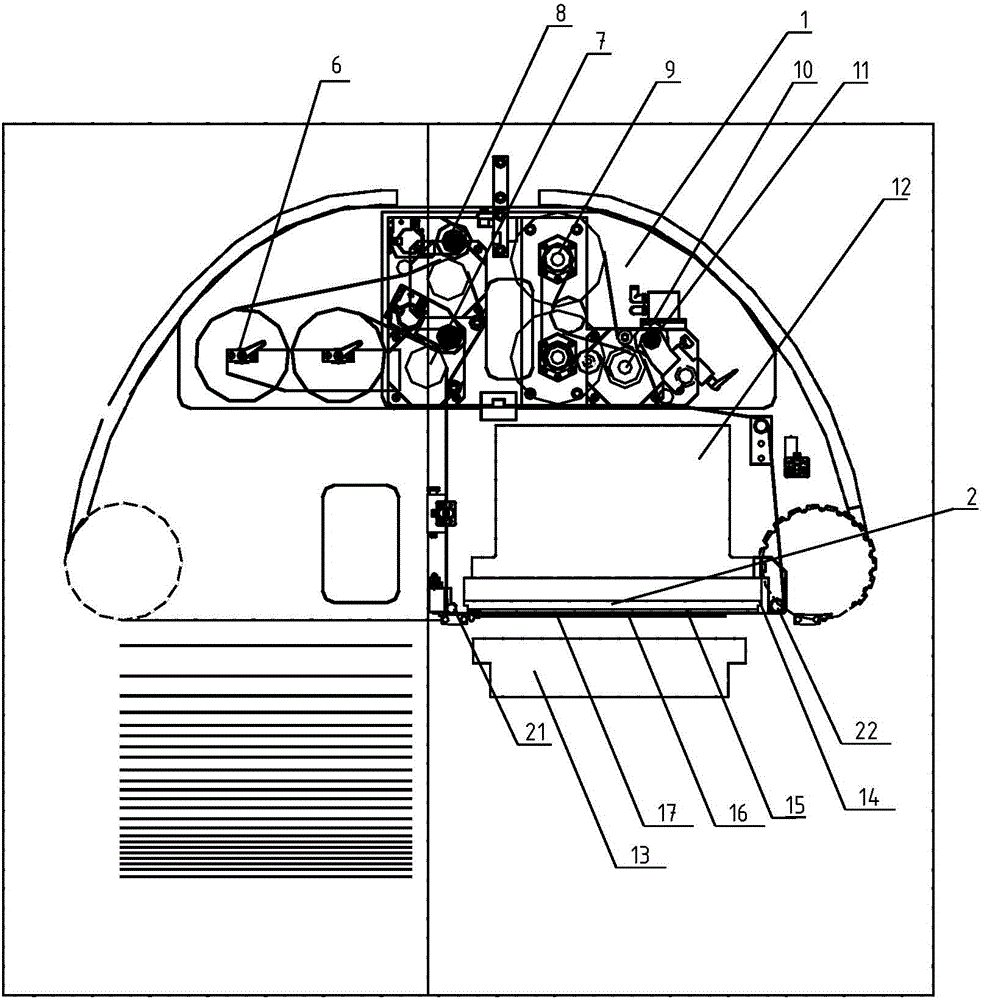

[0041] Such as figure 1 combine figure 2 As shown, an embodiment of the vertical foil sending and receiving integrated hot stamping machine of the present invention includes: the foil sending mechanism 1 sends the gold foil to the hot stamping mechanism 2 to complete the hot stamping, and the waste foil after hot stamping is sent to the foil sending mechanism 1 Recycling and making waste foil rolls, the foil feeding mechanism 1 can be installed and disassembled in the hot stamping machine by sliding through the guide rail 4 fixed on the main wall panel 3, and the foil feeding mechanism 1 is located in the hot stamping mechanism 2 as a whole The vertical layout on the top of the hot stamping machine improves the inconvenient situation that the operator needs to enter the hot stamping machine when installing the foil roll, and the vertical layout can save the space of the whole machine;

[0042] The foil receiving and sending mechanism 1 includes: a foil roll support shaft 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com