Film-covered profile and preparation method thereof

A production method and technology of film-coated profiles, which are applied in the field of surface decoration materials for plastic parts, can solve the problems of limited length, unstable adhesion and adhesion strength, etc., and achieve the effect of realizing diversification and saving process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

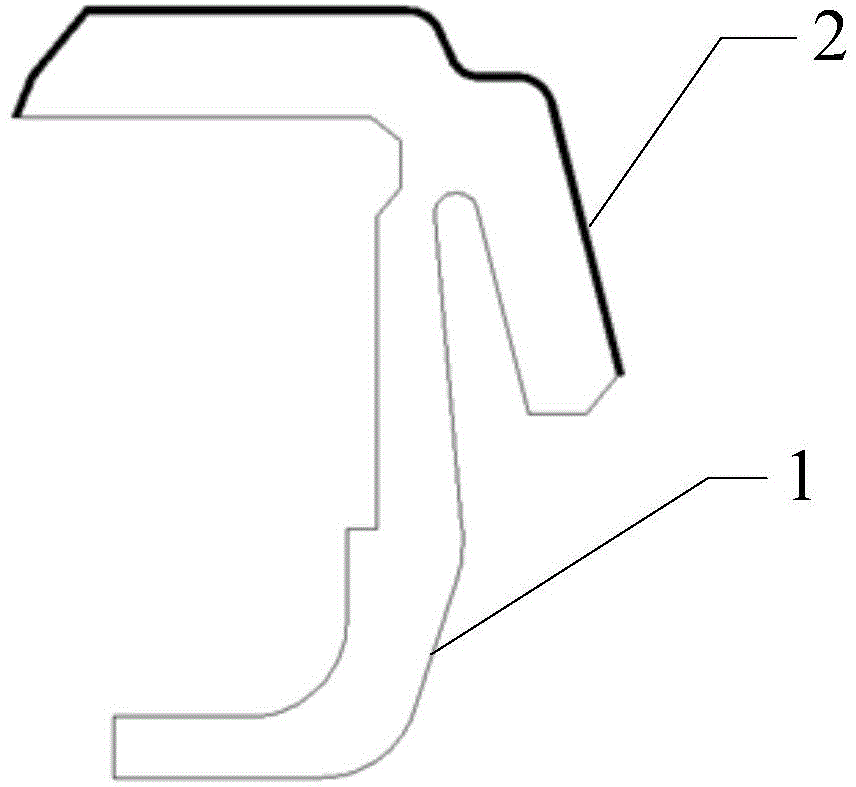

[0019] figure 1 Shown is a film-coated profile with a U-shaped cross section, which consists of a plastic body 1 and a PET film 2 attached to the back of the plastic body 1, and the thickness of the PET film is 0.1mm.

[0020] The manufacture method of the film-coated profile of the present embodiment comprises the following steps:

[0021] (1) Select the film, select the flexible PET film with decorative texture for use; the flexible PET film with decorative texture is a PET film with metallic effects such as wire drawing or mirror surface or natural textures such as wood grain. The thickness of the PET film is 0.1 mm.

[0022] (2) Cut the PET film into film strips that meet the required width;

[0023] (3) Put the PET film strip into the molding cavity of the extrusion mold, and then fuse it with the hot-melt plastic extruded by the extruder in the molding cavity of the mold to extrude a film-coated profile with a decorative effect.

[0024] In the above scheme, in order ...

Embodiment 2

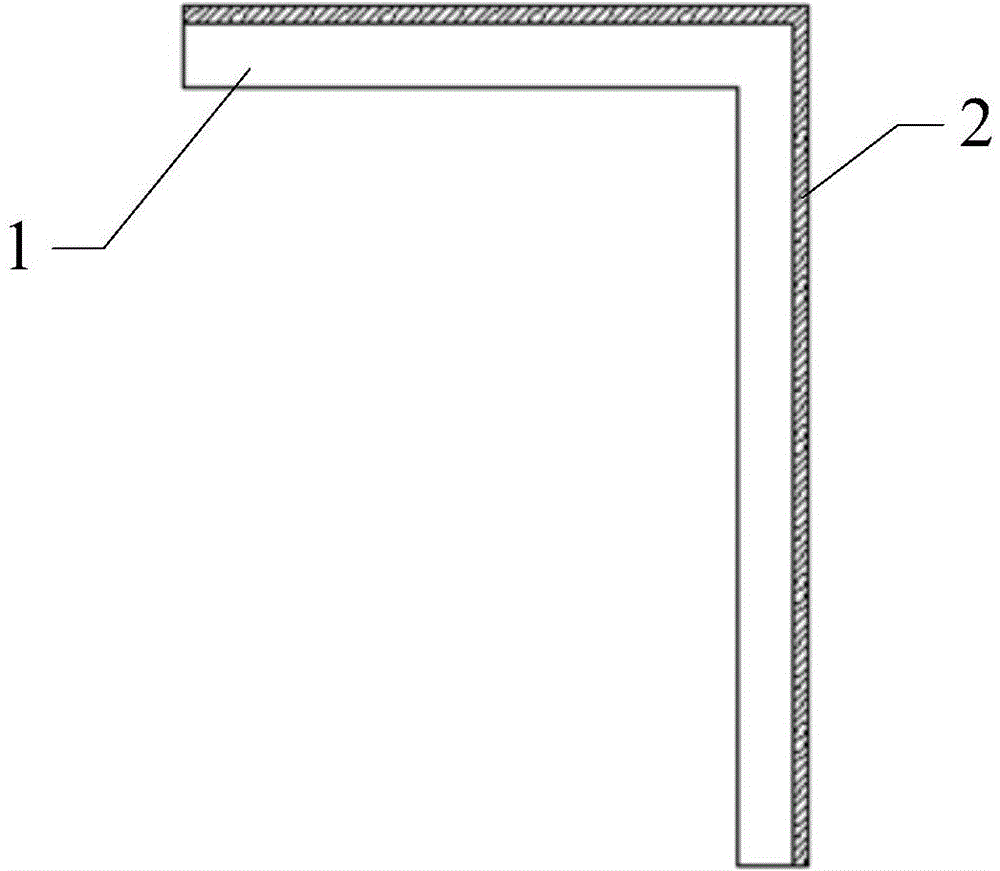

[0026] figure 2 Shown is a film-coated profile with an L-shaped cross section, which consists of a plastic body 1 and a PET film 2 attached to the back of the plastic body 1, and the thickness of the PET film is 1mm.

[0027] The manufacture method of the film-coated profile of the present embodiment comprises the following steps:

[0028] (1) Select the film, select the flexible PET film with decorative texture for use; the flexible PET film with decorative texture is a PET film with metallic effects such as wire drawing or mirror surface or natural textures such as wood grain. The thickness of the PET film was 1 mm.

[0029] (2) Cut the PET film into film strips that meet the required width;

[0030] (3) Put the PET film strip into the molding cavity of the extrusion mold, and then fuse it with the hot-melt plastic extruded by the extruder in the molding cavity of the mold to extrude a film-coated profile with a decorative effect.

[0031] In the above scheme, in order t...

Embodiment 3

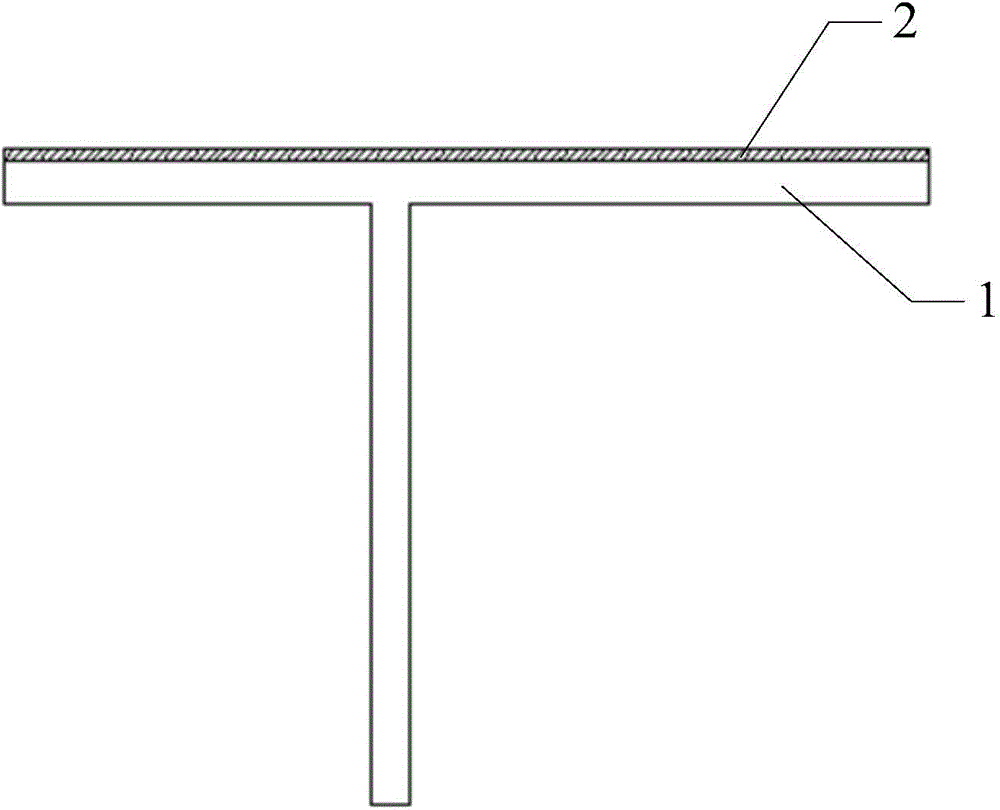

[0033] image 3 Shown is a film-coated profile with a T-shaped cross section, which consists of a plastic body 1 and a PET film 2 attached to the back of the plastic body 1, and the thickness of the PET film is 1mm.

[0034] The manufacture method of the film-coated profile of the present embodiment comprises the following steps:

[0035] (1) Select the film, select the flexible PET film with decorative texture for use; the flexible PET film with decorative texture is a PET film with metallic effects such as wire drawing or mirror surface or natural textures such as wood grain. The thickness of the PET film was 1 mm.

[0036] (2) Cut the PET film into film strips that meet the required width;

[0037] (3) Put the PET film strip into the molding cavity of the extrusion mold, and then fuse it with the hot-melt plastic extruded by the extruder in the molding cavity of the mold to extrude a film-coated profile with a decorative effect.

[0038] In the above scheme, in order to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com