Super-hydrophobic wood and preparation method thereof

A super-hydrophobic, wood technology, applied in the direction of impregnating wood, wood impregnation, wood processing appliances, etc., can solve the problems of complex process, expensive low surface energy substances, etc., achieve simple steps, easy reaction conditions, and good aging resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

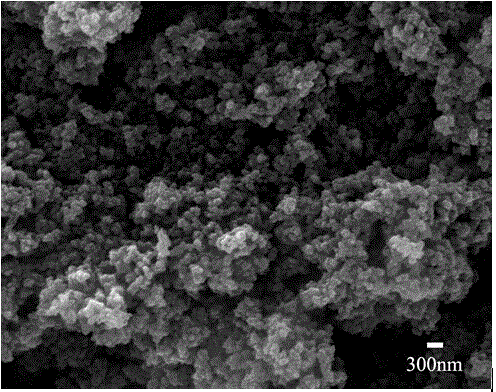

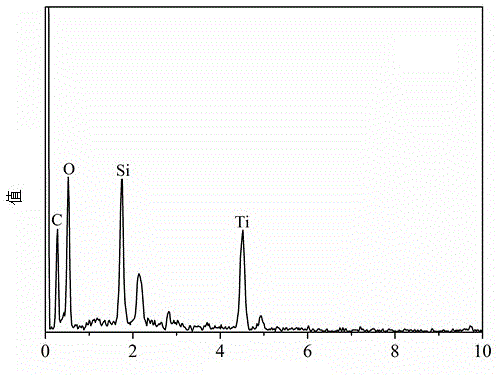

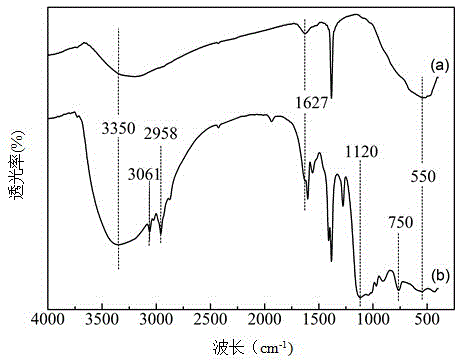

[0031] A superhydrophobic wood of the present invention, the wood surface is a polyvinyl alcohol film layer, and the surface of the polyvinyl alcohol film layer is covered with uniform TiO 2 / SiO 2 Nanostructured composite film layer, TiO 2 / SiO 2 The nanostructures are chemically bonded to the wood / polyvinyl alcohol composite surface through hydroxyl interactions, TiO 2 / SiO 2 The nanostructured composite film layer contains uniform 10-50μm-level grooves and 50-100nm-level protrusions, and is self-assembled with a low surface energy substance vinyltriethoxysilane. The water droplet contact angle of superhydrophobic wood reaches 152°, and the rolling angle less than 5°.

[0032] The preparation method of the superhydrophobic wood of the present embodiment, comprises the following steps:

[0033] (1) Soak the sawn wood in a 3% sodium hydroxide solution for 12 hours, wash it with deionized water under ultrasonic conditions for 10 minutes, then dry the cleaned wood under vac...

Embodiment 2

[0041] A superhydrophobic wood of the present invention, the wood surface is a polyvinyl alcohol film layer, and the surface of the polyvinyl alcohol film layer is covered with uniform TiO 2 / SiO 2 Nanostructured composite film layer, TiO 2 / SiO 2 The nanostructures are chemically bonded to the wood / polyvinyl alcohol composite surface through hydroxyl interactions, TiO 2 / SiO 2 The nanostructured composite film layer contains uniform 30-70μm-level grooves and 20-50nm-level protrusions, and is self-assembled with low surface energy substance methyltrimethoxysilane. The water droplet contact angle of superhydrophobic wood reaches 151°, and the rolling angle is less than 5°.

[0042] The preparation method of the superhydrophobic wood of the present embodiment, comprises the following steps:

[0043] (1) Soak the sawn wood in 8% sodium hydroxide solution for 14 hours, clean it with deionized water under ultrasonic conditions for 15 minutes, then dry the cleaned wood under va...

Embodiment 3

[0051] A superhydrophobic wood of the present invention, the wood surface is a polyvinyl alcohol film layer, and the surface of the polyvinyl alcohol film layer is covered with uniform TiO 2 / SiO 2 Nanostructured composite film layer, TiO 2 / SiO 2 The nanostructures are chemically bonded to the wood / polyvinyl alcohol composite surface through hydroxyl interactions, TiO 2 / SiO 2 The nanostructured composite film layer contains uniform grooves of 50-80 μm and protrusions of 30-100 nm, and is self-assembled with low surface energy substance hexadecyl triethoxysilane. The water droplet contact angle of superhydrophobic wood reaches 153°, The roll angle is less than 5°.

[0052] The preparation method of the superhydrophobic wood of the present embodiment, comprises the following steps:

[0053] (1) Soak the sawn wood in a 5% sodium hydroxide solution for 13 hours, clean it with deionized water for 20 minutes under ultrasonic conditions, then dry the cleaned wood under vacuum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water droplet contact angle | aaaaa | aaaaa |

| Roll angle | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com