Ag/GO/C catalyst and its preparation method and use

A catalyst and solvent technology, applied in the field of catalyst and its preparation, can solve the problems of long reaction time, high cost, large Ag loading, etc., and achieve the effects of simple and easy preparation process, favorable for environmental protection, and speeding up the industrialization process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

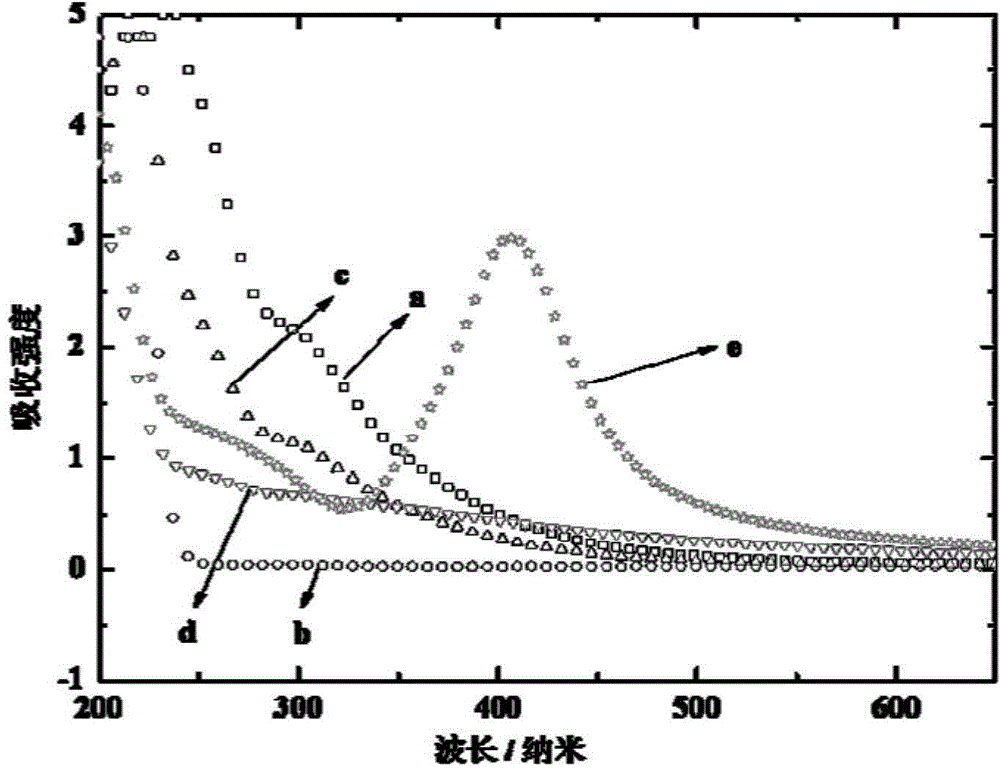

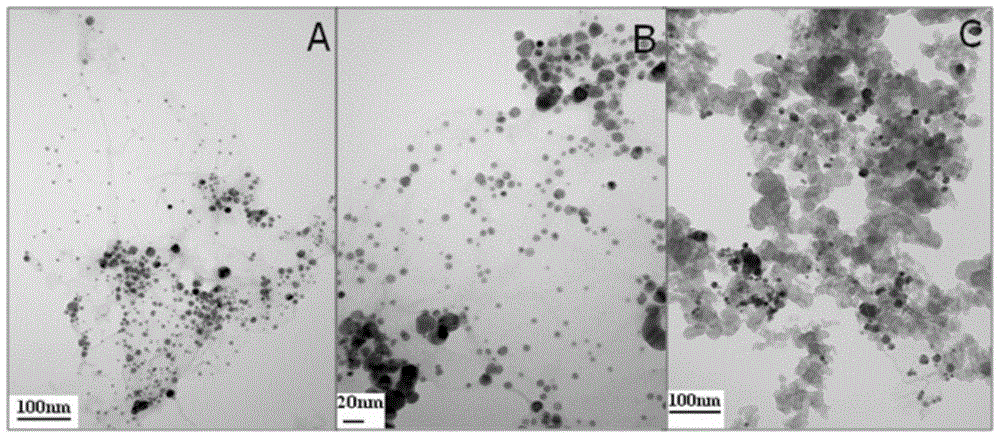

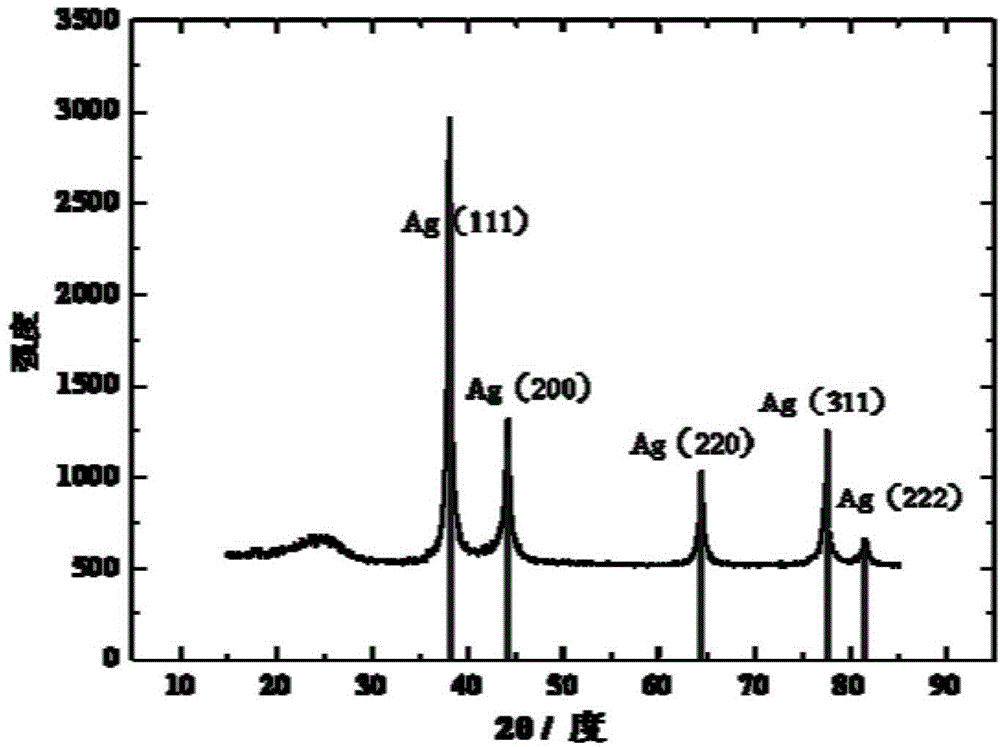

[0046] Weigh 10mg of graphite oxide (GO), disperse in 20ml of deionized water, ultrasonically disperse for 1h; then add 31.5mg of AgNO 3 In the above GO solution, continue to sonicate for 1 h; weigh 15 mg NaOH, dissolve it in 15 ml deionized water, slowly drop the NaOH solution into the reaction solution under magnetic stirring; raise the temperature to 100 °C, and reflux for 2 h to obtain a brown-black colloid; weigh Take 70mg of Vulcan XC-72R carbon black and add it to 40ml of deionized water, sonicate for 30 minutes and pour it into the reaction solution; cool to room temperature, filter with suction, wash with 50ml of water, drain it and put it in the refrigerator to freeze overnight; take out the catalyst in the refrigerator Put it into a freeze dryer and dry it for 6h to get the target product Ag / GO / C catalyst. The mass content of Ag in the catalyst was 20%, and that of GO was 10%.

Embodiment 2

[0048] Weigh 10mg of graphite oxide (GO), disperse in 20ml of deionized water, ultrasonically disperse for 1h; then add 31.5mg of AgNO 3In the above GO solution, continue to sonicate for 30min; weigh 70mg VulcanXC-72R and add it to 40ml deionized water, after sonicating for 30min, pour GO and AgNO 3 In the solution, continue to sonicate for 30min; weigh 15mg NaOH, dissolve it in 15ml deionized water, slowly drop the NaOH solution into the reaction solution under magnetic stirring; raise the temperature to 100°C, reflux for 2h; cool to room temperature, filter with Wash with 50ml of water, drain and freeze overnight in the refrigerator; take out the catalyst in the refrigerator and put it in a freeze dryer to dry for 6 hours to obtain the target product Ag / GO / C catalyst. The mass content of Ag in the catalyst was 20%, and that of GO was 10%.

Embodiment 3

[0050] Weigh 20mg of graphite oxide (GO), disperse in 20ml of deionized water, ultrasonically disperse for 1h; then add 31.5mg of AgNO 3 In the above GO solution, continue to sonicate for 1h; weigh 15mg NaOH, dissolve it in 15ml deionized water, slowly drop the NaOH solution into the reaction solution under magnetic stirring; raise the temperature to 100°C, and reflux for 2h to obtain a brown-black colloid; weigh Take 60mg of Vulcan XC-72R carbon black and add it to 40ml of deionized water, sonicate for 30min and pour it into the reaction solution; cool to room temperature, filter with suction, wash with 50ml of water, drain it and put it in the refrigerator to freeze overnight; take out the catalyst in the refrigerator Put it into a freeze dryer and dry it for 6h to get the target product Ag / GO / C catalyst. The mass content of Ag in the catalyst was 20%, and that of GO was 20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com