Hyperbranched polymer functionalized mesoporous material and application thereof

A technology of hyperbranched polymers and mesoporous materials, applied in water pollutants, other chemical processes, chemical instruments and methods, etc., can solve the problems of poor stability of functionalized modified components, complex synthesis steps of modified mesoporous silicon materials, Organic groups block pores and other problems, to achieve the effect of strong plasticity, short cycle and efficient adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Weigh quantitative polyethylene oxide-polypropylene oxide-polyethylene oxide (P123) into deionized water, stir and dissolve at 30°C, control the concentration of P123 to 14.50 g / L; add 2mol / L HCL solution , control the mass volume ratio (g / mL) of P123 and HCL solution to 1:35, stir until uniform, and obtain P123 acidic solution.

[0031] Add 2-cyanotriethoxysilane (CTES) to the P123 acidic solution, control the mass ratio of CTES to P123 to 1:11.76, stir at 30°C at a speed of 400r / min for 40 min, and add orthosilicon drop by drop Ethyl acetate (TEOS), the mass ratio of TEOS and P123 was controlled to be 2.15:1, stirred at a speed of 400r / min at 40°C for 24h to obtain a silica sol precursor.

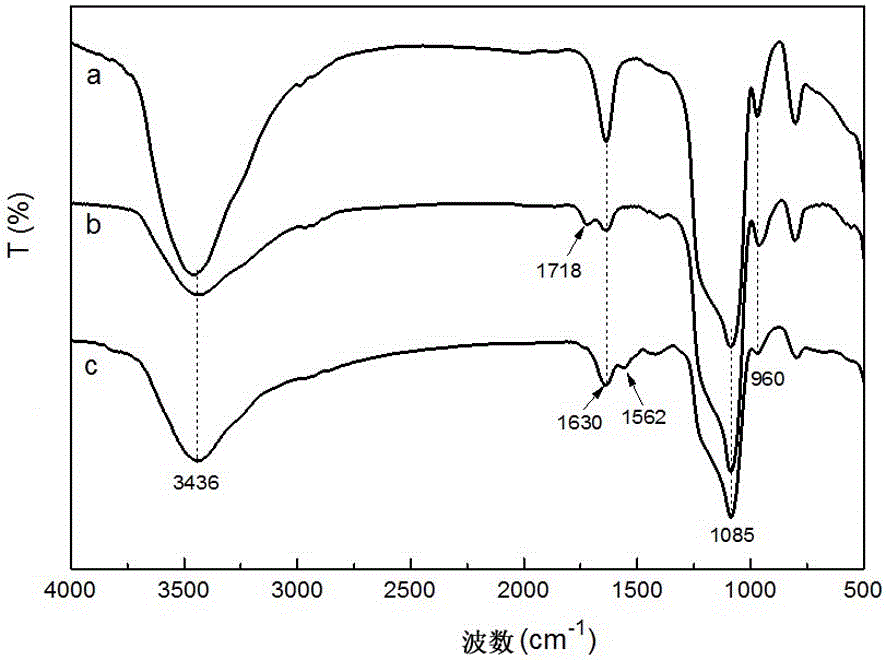

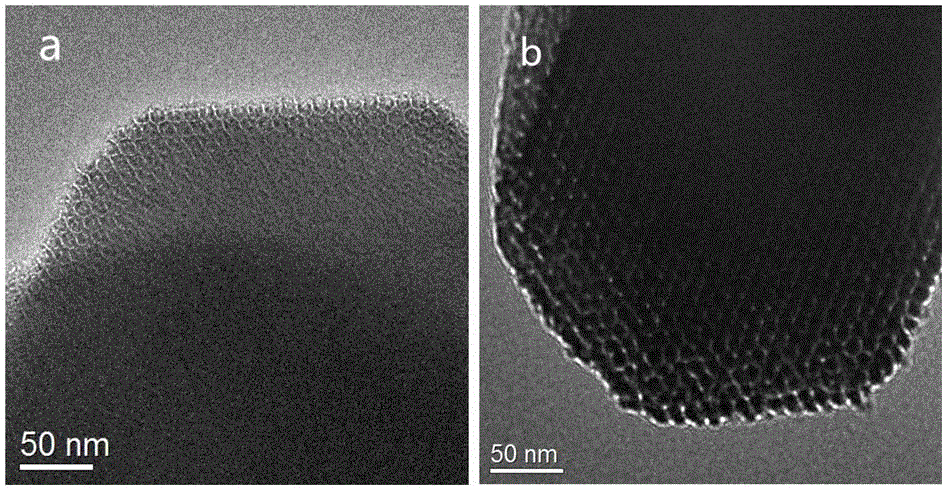

[0032] Move the silica sol precursor to a reactor lined with tetrafluoroethylene for crystallization at 90°C for 24 hours, filter the resulting white precipitate, and dry it in vacuum at 80°C to obtain a white powder that is cyano-functionalized mesoporous silicon SBA -15 (denoted a...

Embodiment 2

[0041] Weigh quantitative polyethylene oxide-polypropylene oxide-polyethylene oxide (P123) into deionized water, stir and dissolve at 30 °C, and control the concentration of P123 to 25.86 g / L. Then add 2mol / L HCL solution, control the mass volume ratio (g / mL) of P123 and HCL solution to 1:60, stir until uniform, and obtain P123 acidic solution.

[0042] Add 3-cyanotriethoxysilane (CETES) to the P123 acidic solution, control the mass ratio of CETES to P123 to 1:6.49, stir at 45°C at a speed of 600r / min for 30 min, and add orthosilicon drop by drop Acetate methyl ester (TMOS), control the mass ratio of TMOS and P123 to 1.54:1, and stir at 50°C at a speed of 600r / min for 12h to obtain a silica sol precursor.

[0043] Move the silica sol precursor to a reactor lined with tetrafluoroethylene for crystallization at 80°C for 36 hours, filter the resulting white precipitate, and dry it in vacuum at 80°C to obtain a white powder that is cyano-functionalized mesoporous silicon SBA -15 ...

Embodiment 3

[0048] Weigh quantitative polyethylene oxide-polypropylene oxide-polyethylene oxide (P123) into deionized water, stir and dissolve at 30 °C, and control the concentration of P123 to 7.86 g / L. Then add 2mol / L HCL solution, control the mass volume ratio (g / mL) of P123 and HCL solution to 1:40, stir until uniform, and obtain P123 acidic solution.

[0049] Add 2-cyanotriethoxysilane (CTES) to the P123 acidic solution, control the mass ratio of CTES to P123 to 1:7.70, stir at 60°C at a speed of 400r / min for 30 min, and add orthosilicon drop by drop Ethyl acetate (TEOS), the mass ratio of TEOS and P123 was controlled to be 2.65:1, and stirred at 500r / min at 60°C for 8h to obtain a silica sol precursor.

[0050] Move the silica sol precursor to a reactor lined with tetrafluoroethylene for crystallization at 110°C for 12 hours, filter the resulting white precipitate, and dry it in vacuum at 80°C to obtain a white powder that is cyano-functionalized mesoporous silicon SBA -15 (CN-SBA-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturated adsorption capacity | aaaaa | aaaaa |

| Saturated adsorption capacity | aaaaa | aaaaa |

| Saturated adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com