Preparation method of mesoporous material for adsorption of heavy metal ions and dye pollutants

A technology for the adsorption of heavy metals and mesoporous materials, applied in the directions of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc. , the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

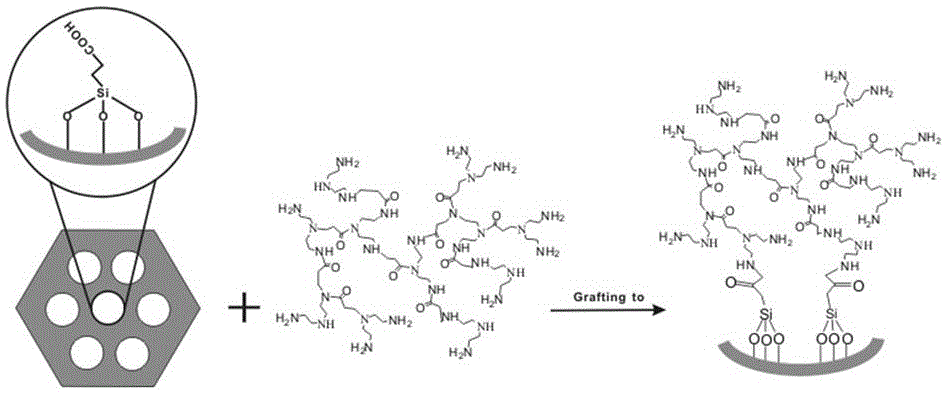

[0029] See attached figure 1 , is a schematic diagram of the process of preparing functionalized mesoporous silicon material in this example. First, cyano-modified mesoporous silicon was synthesized by co-condensation polymerization, and then carboxy-functionalized mesoporous silicon was obtained by carboxylation, and then amino-terminated hyperbranched polymers were grafted on the carboxyl-functionalized mesoporous silicon by the "grafting to" strategy, thereby A carboxylated mesoporous silicon / amino-terminated hyperbranched polymer hybrid material was obtained.

[0030] Concrete preparation steps are as follows:

[0031] Weigh quantitative polyethylene oxide-polypropylene oxide-polyethylene oxide (P123) into deionized water, stir and dissolve at 30°C, control the concentration of P123 to 14.50 g / L; add 2mol / L HCL solution , control the mass volume ratio (g / mL) of P123 and HCL solution to 1:35, stir until uniform, and obtain P123 acidic solution.

[0032] Add 2-cyanotriethox...

Embodiment 2

[0042] Weigh quantitative polyethylene oxide-polypropylene oxide-polyethylene oxide (P123) into deionized water, stir and dissolve at 30 °C, and control the concentration of P123 to 25.86 g / L. Then add 2mol / L HCL solution, control the mass volume ratio (g / mL) of P123 and HCL solution to 1:60, stir until uniform, and obtain P123 acidic solution.

[0043] Add 3-cyanotriethoxysilane (CETES) to the P123 acidic solution, control the mass ratio of CETES to P123 to 1:6.49, stir at 45°C at a speed of 600r / min for 30 min, and add orthosilicon drop by drop Acetate methyl ester (TMOS), control the mass ratio of TMOS and P123 to 1.54:1, and stir at 50°C at a speed of 600r / min for 12h to obtain a silica sol precursor.

[0044] Move the silica sol precursor to a reactor lined with tetrafluoroethylene for crystallization at 80°C for 36 hours, filter the resulting white precipitate, and dry it in vacuum at 80°C to obtain a white powder that is cyano-functionalized mesoporous silicon SBA -15 ...

Embodiment 3

[0049] Weigh quantitative polyethylene oxide-polypropylene oxide-polyethylene oxide (P123) into deionized water, stir and dissolve at 30 °C, and control the concentration of P123 to 7.86 g / L. Then add 2mol / L HCL solution, control the mass volume ratio (g / mL) of P123 and HCL solution to 1:40, stir until uniform, and obtain P123 acidic solution.

[0050] Add 2-cyanotriethoxysilane (CTES) to the P123 acidic solution, control the mass ratio of CTES to P123 to 1:7.70, stir at 60°C at a speed of 400r / min for 30 min, and add orthosilicon drop by drop Ethyl acetate (TEOS), the mass ratio of TEOS and P123 was controlled to be 2.65:1, and stirred at 500r / min at 60°C for 8h to obtain a silica sol precursor.

[0051] Move the silica sol precursor to a reactor lined with tetrafluoroethylene for crystallization at 110°C for 12 hours, filter the resulting white precipitate, and dry it in vacuum at 80°C to obtain a white powder that is cyano-functionalized mesoporous silicon SBA -15 (CN-SBA-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com