Inorganic ceramic ultrafiltration membrane cleaning agent and preparation method thereof

A technology of inorganic ceramics and ultrafiltration membranes, applied in the field of cleaning agents, can solve problems such as failure to achieve cleaning effects, and achieve the effects of reducing the number of replacements, prolonging service life, and achieving excellent cleaning effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

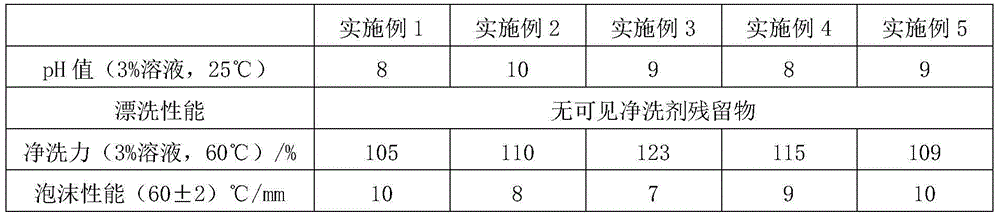

Examples

Embodiment 1

[0020] An inorganic ceramic ultrafiltration membrane cleaning agent, comprising in parts by weight: 3 parts of coconut oil fatty acid monoethanolamide, 2 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 1 part of acetate starch, diethyl sulfosuccinate 4 parts of sodium hexametaphosphate, 1 part of sodium hexametaphosphate, 2 parts of sodium tripolyphosphate, 0.2 parts of styrene / maleic anhydride / octadecylamine terpolymer, 1 part of diatomaceous earth, 3 parts of protease, 4 parts of alcohol amines 1 part, corrosion inhibitor 1 part, deionized water 3 parts.

[0021] The alcohol amines are diethanolamine; the corrosion inhibitor is sodium silicate.

[0022] The preparation method of above-mentioned inorganic ceramic ultrafiltration membrane cleaning agent, comprises the following steps:

[0023] Step 1, add coconut oil fatty acid monoethanolamide, acetate starch, sodium diisooctyl sulfonate and sodium hexametaphosphate to 1 / 3 parts by weight of deionized water, kee...

Embodiment 2

[0027] An inorganic ceramic ultrafiltration membrane cleaning agent, comprising in parts by weight: 5 parts of coconut oil fatty acid monoethanolamide, 4 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 2 parts of acetate starch, diethyl sulfosuccinate 6 parts of sodium hexametaphosphate, 2 parts of sodium hexametaphosphate, 4 parts of sodium tripolyphosphate, 0.5 parts of styrene / maleic anhydride / octadecylamine terpolymer, 3 parts of diatomaceous earth, 4 parts of protease, 5 parts of alcohol amines , 2 parts of corrosion inhibitor, 5 parts of deionized water.

[0028] The alcohol amines are triethanolamine; the corrosion inhibitor is sodium metasilicate.

[0029] The preparation method of above-mentioned inorganic ceramic ultrafiltration membrane cleaning agent, comprises the following steps:

[0030] Step 1, add coconut oil fatty acid monoethanolamide, acetate starch, sodium diisooctyl sulfonate and sodium hexametaphosphate to 1 / 3 parts by weight of deionized w...

Embodiment 3

[0034] An inorganic ceramic ultrafiltration membrane cleaning agent, comprising in parts by weight: 6 parts of coconut oil fatty acid monoethanolamide, 5 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 3 parts of acetate starch, diethyl sulfosuccinate 8 parts of sodium hexametaphosphate, 4 parts of sodium hexametaphosphate, 7 parts of sodium tripolyphosphate, 0.9 parts of styrene / maleic anhydride / octadecylamine terpolymer, 6 parts of diatomaceous earth, 6 parts of protease, 6 parts of alcohol amines parts, 3 parts of corrosion inhibitor, 8 parts of deionized water.

[0035] The alcohol amines are diisopropanolamine; the corrosion inhibitor is sodium silicate.

[0036] The preparation method of above-mentioned inorganic ceramic ultrafiltration membrane cleaning agent, comprises the following steps:

[0037] Step 1, add coconut oil fatty acid monoethanolamide, acetate starch, sodium diisooctyl sulfonate and sodium hexametaphosphate to 1 / 3 parts by weight of deioniz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com