Denitration demisting device and method after wet desulfurization

A technology of wet desulfurization and demisting devices, which is applied in the direction of combined devices, separation methods, chemical instruments and methods, etc., to achieve the effects of improving NOx mass transfer and absorption capacity, improving demisting effect, and improving reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

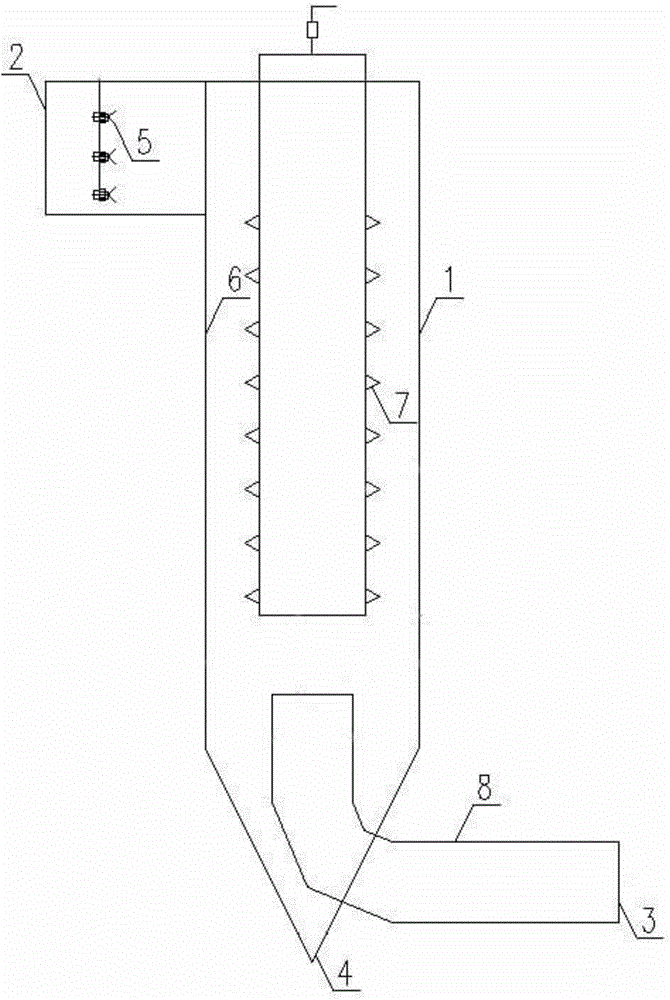

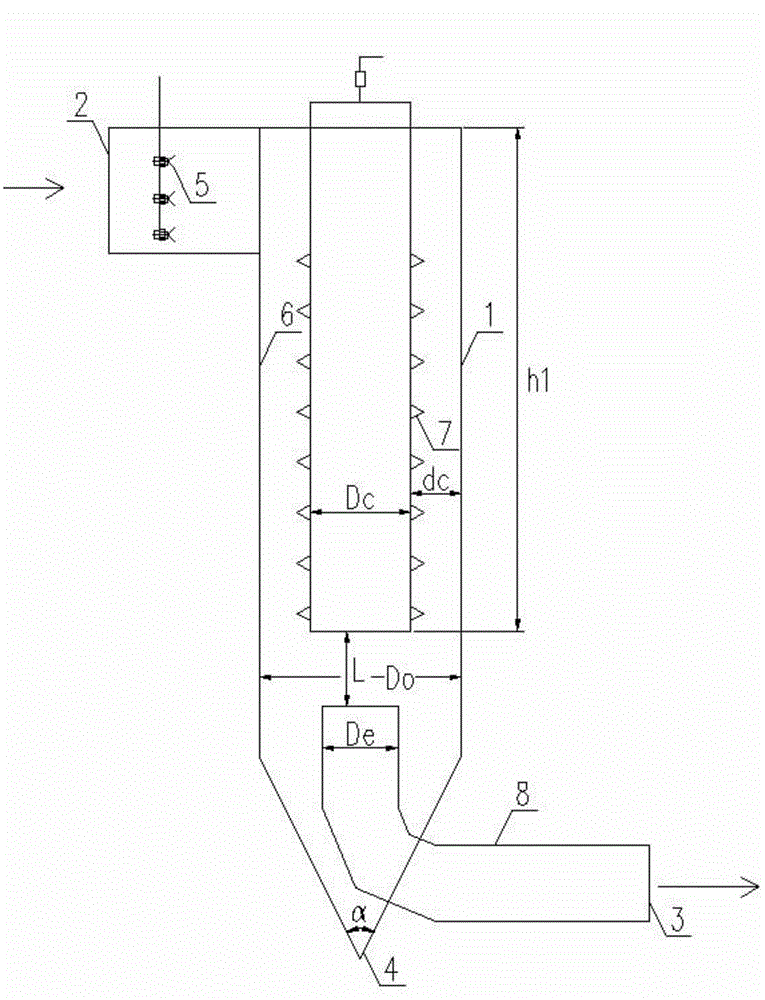

[0030] Embodiment 1, figure 1A device and method for denitrification and demisting after wet desulfurization are given, which combine the two functions of denitrification and demisting.

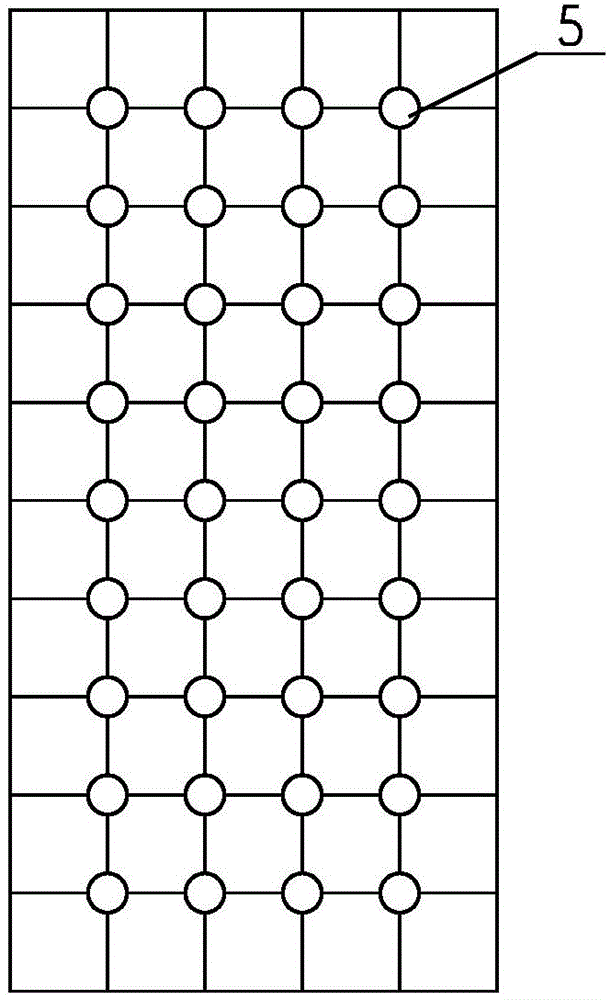

[0031] The denitrification and demisting device and method after wet desulfurization of the present invention include a cylinder body 1, which is a cylindrical inner chamber (through the cylindrical inner chamber, the airflow entering the cylinder body 1 from the side can be Form the movement mode of the helix), the cylindrical inner cavity of the cylinder body 1 is provided with an electrostatic field (ie, an electrostatic channel), and the electrostatic field is composed of two parts, one of which is the cylindrical inner cavity of the cylinder body 1 The discharge electrode plate 6 composed of the wall, and the other part is the guide electrode 7, the guide electrode 7 is a prickly electrode, that is, it is formed by adding a plurality of rows of regular pricks on the cylindrical guide col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com