Growth factor nanotube slow-release system used for osseointegration and preparation method and application thereof

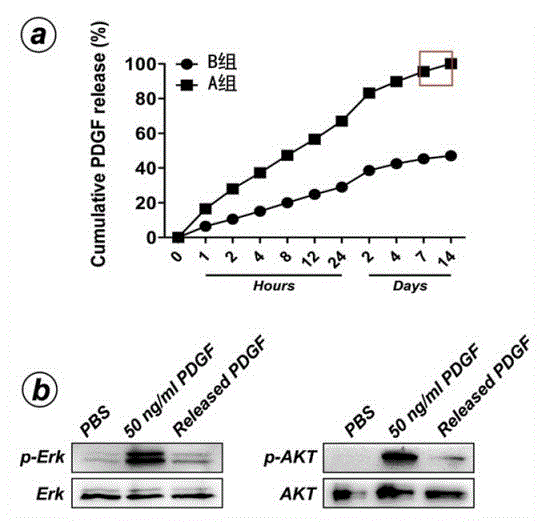

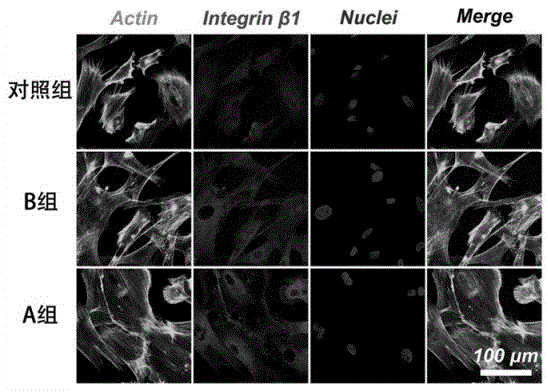

A growth factor and nanotube technology, used in medical science, surgery, etc., can solve the problems that the biological activity of growth factors cannot be maintained for a long time, the research has not been reported in the literature, and there is explosive release. The amount of drug and the effect of promoting osseointegration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1. Nanotube modification and drug loading on the surface of titanium sheet

[0029] Step 1. Nanotube modification on the surface of titanium sheet

[0030] A titanium alloy material with a size of 10 × 10 × 1 mm is placed in an ethanol solution for ultrasonic cleaning for 30 minutes; then replaced with deionized water and ultrasonic cleaning is continued for 30 minutes. Repeat the operation 2 times; place the cleaned titanium sheet Acid etching in 5 wt% oxalic acid solution at 100°C for 2 hours; finally, it is placed in 1.0 wt% hydrofluoric acid electrolyte using constant current direct current anodizing (voltage 20V) for 30 minutes to prepare nanometers with a diameter of about 70nm Tube coating.

[0031] Step 2: Vacuum suction promotes the loading of rhPDGF-BB with nanotubes on the surface of the titanium sheet

[0032] In the commercial GEM 21S kit, the concentration of the original rhPDGF-BB solution is 300μg / ml, and it is diluted to a working concentration of 50μg...

Embodiment 2

[0033] Example 2. Nanotube modification and drug loading on the surface of titanium sheet

[0034] Step 1. Nanotube modification on the surface of titanium sheet

[0035] Titanium alloy material with a size of 10 × 10 × 1 mm is placed in an ethanol solution for ultrasonic cleaning for 30 minutes; then replaced with deionized water and ultrasonic cleaning is continued for 30 minutes. Repeat the operation 2 times; place the cleaned titanium sheet Acid etching in 5 wt% oxalic acid solution at 100°C for 2 hours; finally placed in 1.0 wt% hydrofluoric acid electrolyte and used constant current direct current anodization (voltage 20V) for 30 minutes to prepare nanometers with a diameter of about 70nm Tube coating.

[0036] Step 2: Vacuum suction promotes the loading of rhPDGF-BB with nanotubes on the surface of the titanium sheet

[0037] In the commercial GEM 21S kit, the concentration of the original rhPDGF-BB solution is 300μg / ml. Use sterile medical water to dilute it to a working conc...

Embodiment 3

[0038] Example 3. Nanotube modification and drug loading on the surface of titanium sheet

[0039] Step 1. Nanotube modification on the surface of titanium sheet

[0040] A titanium alloy material with a size of 10 × 10 × 1 mm is placed in an ethanol solution for ultrasonic cleaning for 30 minutes; then replaced with deionized water and ultrasonic cleaning is continued for 30 minutes. Repeat the operation 2 times; place the cleaned titanium sheet Acid etching in 5 wt% oxalic acid solution at 100°C for 2 hours; finally placed in 1.0 wt% hydrofluoric acid electrolyte and used constant current direct current anodization (voltage 20V) for 30 minutes to prepare nanometers with a diameter of about 70nm Tube coating.

[0041] Step 2: Vacuum suction promotes the loading of rhPDGF-BB with nanotubes on the surface of the titanium sheet

[0042] In the commercial GEM 21S kit, the concentration of the rhPDGF-BB stock solution is 300μg / ml, and 50μl of this solution is dripped onto the nanotube co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com