Burley tobacco strip fuming processing method

A processing method and technology for burley tobacco, which are applied in the fields of tobacco, tobacco preparation, tobacco processing, etc., can solve the problems of large quality difference, poor quality uniformity, large batch quality difference, etc., and achieve clear positioning, reduced energy loss, and differentiation. obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

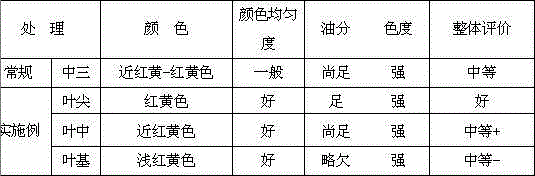

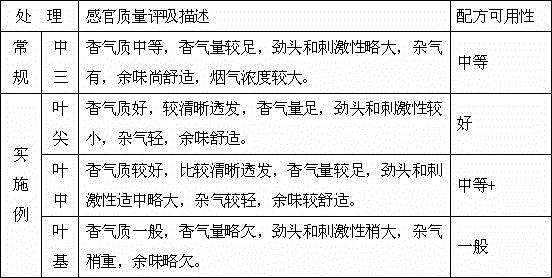

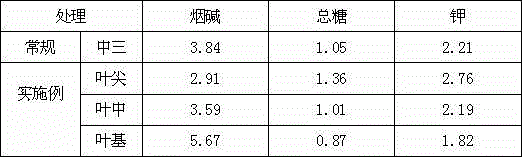

Examples

Embodiment

[0015] A processing method for smoking burley tobacco sheets, comprising the following steps:

[0016] (1) Ripening of mature tobacco leaves by removing main veins: After removing the main veins of mature harvested Burley tobacco, two and a half tobacco leaves are obtained, folded in half, stringed normally, air-cured, and taken out after the browning period is over. The main vein is aired separately.

[0017] 2) Segmentation processing: Stack the half-sheets of Burley tobacco neatly, and cut them into 20-30 sheets as a stack, 2 knives and 3 pieces, which are leaf tip, leaf center and leaf base in sequence.

[0018] 3) Re-roasting: The segmented tobacco obtained in step 2) is directly re-roasted, followed by leaf moistening, drying, cooling and re-moisture, packaging, etc.; the main vein (tobacco stem) is re-roasted separately.

[0019] In the step 2), the first cutting point is located at 1 / 3~1 / 2 away from the leaf tip, cut along the branch vein; the second cutting point is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com