A kind of sterilizing and antiseptic method of soy sauce

A soy sauce and ultra-high pressure sterilization technology, applied in food science, food preservation, application, etc., can solve problems such as difficult to achieve large-scale production and intensive management, increased browning, reduction of amino acid nitrogen and reducing sugar, and achieve safety Anti-corrosion and fresh-keeping technology, inhibiting the germination of spores, and maintaining the effect of nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

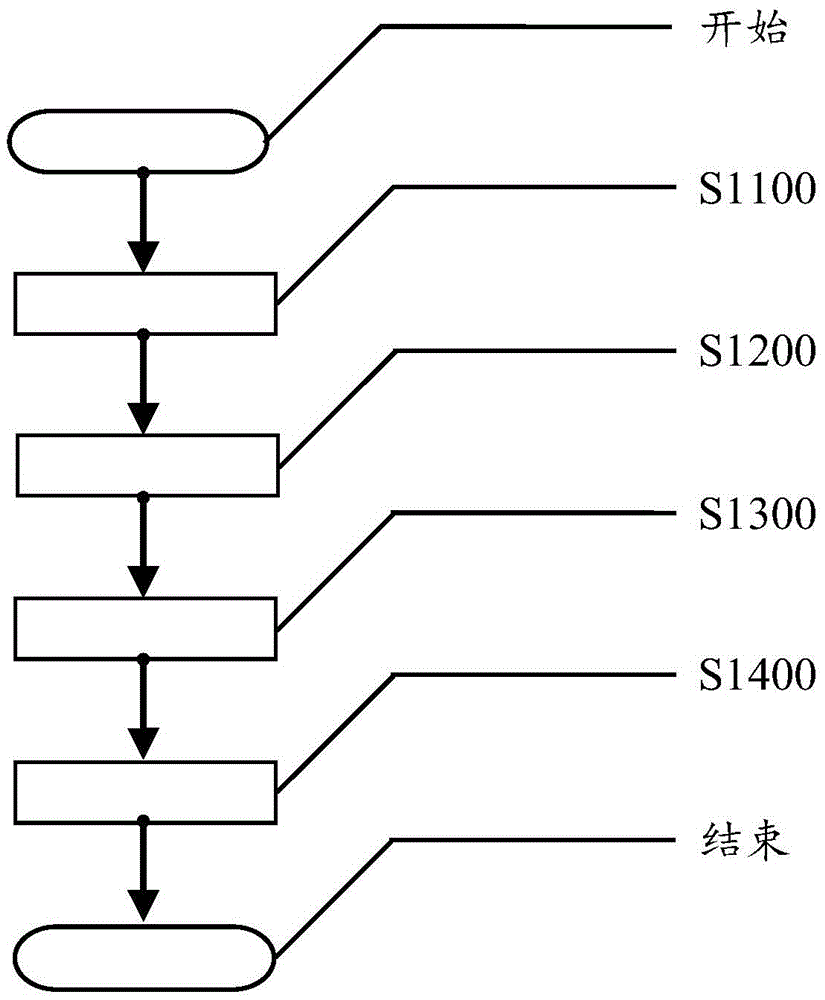

[0031] according to figure 1 The sterilizing and antiseptic method of a kind of soy sauce of the present invention shown, the steps are as follows:

[0032] Raw oil preparation step S1100: leaching the soy sauce fermented grains to obtain 100 kg of raw oil.

[0033] Ultra-high pressure sterilization step S1200: performing ultra-high pressure sterilization on raw oil. The treatment pressure is 300MPa, the treatment time is 30min, and the treatment temperature is 60°C.

[0034] Step S1300 of adding a biological antibacterial agent: adding 120 micrograms of Nisin to every milliliter of raw oil.

[0035] Filtration and clarification step S1400: The treated raw oil is filtered and clarified to obtain soy sauce.

Embodiment 2

[0037] according to figure 1 The sterilizing and antiseptic method of a kind of soy sauce of the present invention shown, the steps are as follows:

[0038] Raw oil preparation step S1100: leaching the soy sauce fermented grains to obtain 100 kg of raw oil.

[0039] Ultra-high pressure sterilization step S1200: performing ultra-high pressure sterilization on raw oil. The treatment pressure is 500MPa, the treatment time is 15min, and the treatment temperature is 30°C.

[0040] Step S1300 of adding a biological antibacterial agent: adding 50 micrograms of Nisin to every milliliter of raw oil.

[0041] Filtration and clarification step S1400: The treated raw oil is filtered and clarified to obtain soy sauce.

Embodiment 3

[0043] according to figure 1 The sterilizing and antiseptic method of a kind of soy sauce of the present invention shown, the steps are as follows:

[0044] Raw oil preparation step S1100: leaching the soy sauce fermented grains to obtain 100 kg of raw oil.

[0045] Ultra-high pressure sterilization step S1200: performing ultra-high pressure sterilization on raw oil. The processing pressure is 700MPa, the processing time is 6min, and the processing temperature is 45°C.

[0046] Step S1300 of adding a biological antibacterial agent: adding 100 micrograms of Nisin to every milliliter of raw oil.

[0047] Filtration and clarification step S1400: The treated raw oil is filtered and clarified to obtain soy sauce.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com