Dual-function heat indicator and method of manufacture

An indicator, dual-function technology, applied in the field of visual indicators, which can solve problems such as degradation, failure quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

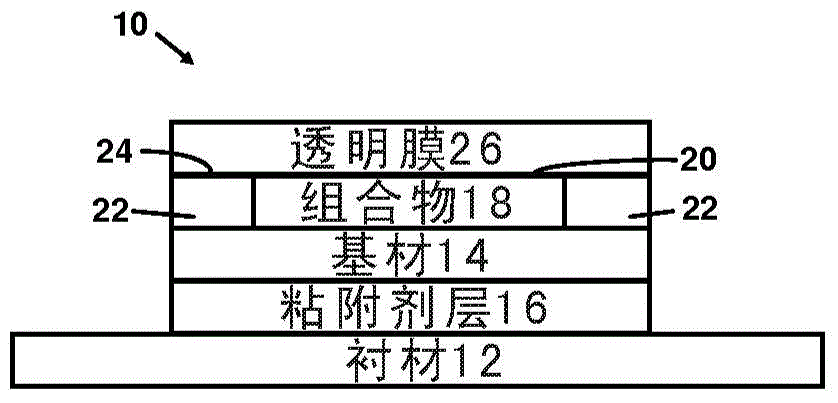

[0149] The coating composition can be prepared, for example, by the method of preparing a peak indicator composition described herein, except without the first reactant and the second reactant. Thus, the color forming function of the first reactant and the second reactant can be replaced by the meltable particulate colored material. Using the previously described example of black dyed hecosane wax, prior to activation of the peak exposure indicator, the dyed wax particles may have a light color such as white due to light scattering. However, the inherent black color of the dyed wax particles quickly becomes apparent after the hehenicane wax melts in response to exposure to ambient temperatures of about 40°C or greater (the melting point of the heicanodecane wax). After melting, the small, dyed wax particles coalesce and cease to scatter light, revealing their inherent color.

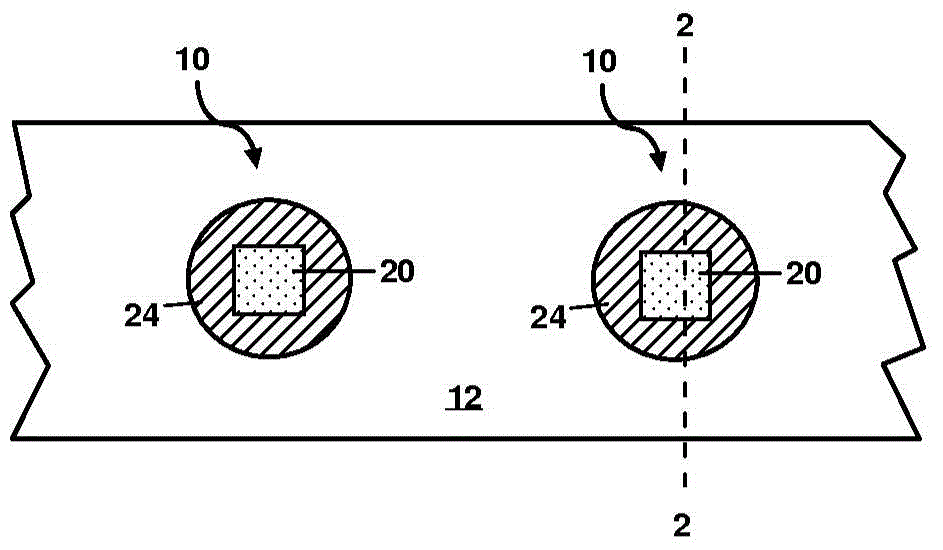

[0150]In another aspect, example embodiments of the present invention provide a thermal event indica...

Embodiment 1

[0192] Example 1: Fabrication of a dual heat indicator prototype

[0193] Prototype indicators were fabricated by laminating VVM14-type cumulative heat indicators printed on transparent film to commercially available thermal paper or prefabricated thermal paper. The VVM14-type cumulative heat indicator is a prototype cumulative heat indicator formulated to respond to approximately 14 days at 37°C, and is expected to be similar to the commercially available HEATmarker VVM14 (available from Temptime Corporation). VVM14 has good temperature characteristic response characteristics and is manufactured to meet the World Health Organization requirements in PQS Performance Specification, Vaccine Vial Monitor WHO / PQS / E06 / IN05.2 of 26 July 2011. It responded in 14 days at 37°C, 90 days at 25°C and over 3 years at 5°C. Prototype indicators were fabricated on a Gallus 250I press. Two trials were performed, the latter evaluating a thinner clear polyester film as an improvement. Both set...

Embodiment 2

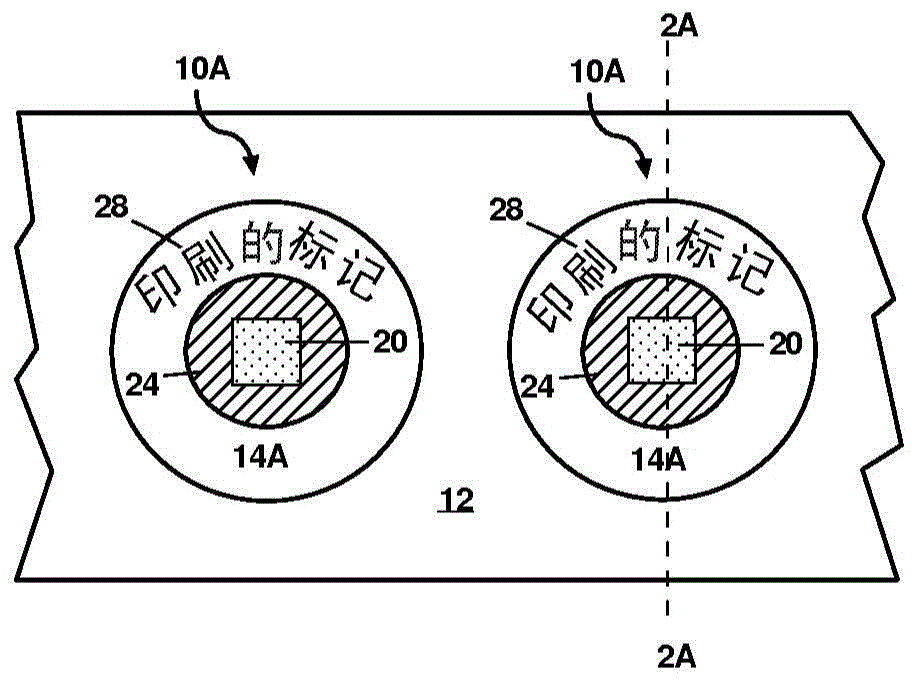

[0206] Example 2: For illustration Figure 7 The dual heat indicator prototype of the example embodiment shown in

[0207] A prototype dual heat indicator was fabricated by hand by laminating a VVM14-type cumulative heat indicator printed on a transparent film to a commercially available or prefabricated threshold indicator. Cumulative indicator components were printed on DuPont Teijin Films using a Gallus 250I printing press with color shifting "active" diacetylene ink and static "reference ink" TM Made in 561, DuPont Teijin Films TM 561 is a 0.005 inch thick clear polyester film. "Active" inks are manufactured in-house by dispersing "KE" (2,4-Hexadiyn-1,6-bis(ethylurea)) powder in a solvent-based nitrocellulose ink according to the procedure of US Patent 8067483 of. The amount of KE in the ink and the amount of ink applied to the polyester film was chosen such that a color match between the temperature-sensitive reactive ink and the temperature-insensitive reference ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com