cooling module

A technology of heat dissipation module and heat sink, applied in lighting and heating equipment, cooling/ventilation/heating renovation, cooling/heating device of lighting device, etc. good question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to make the above and other purposes, features and advantages of the present invention more comprehensible, the preferred embodiments of the present invention are specifically cited below, together with the accompanying drawings, as follows:

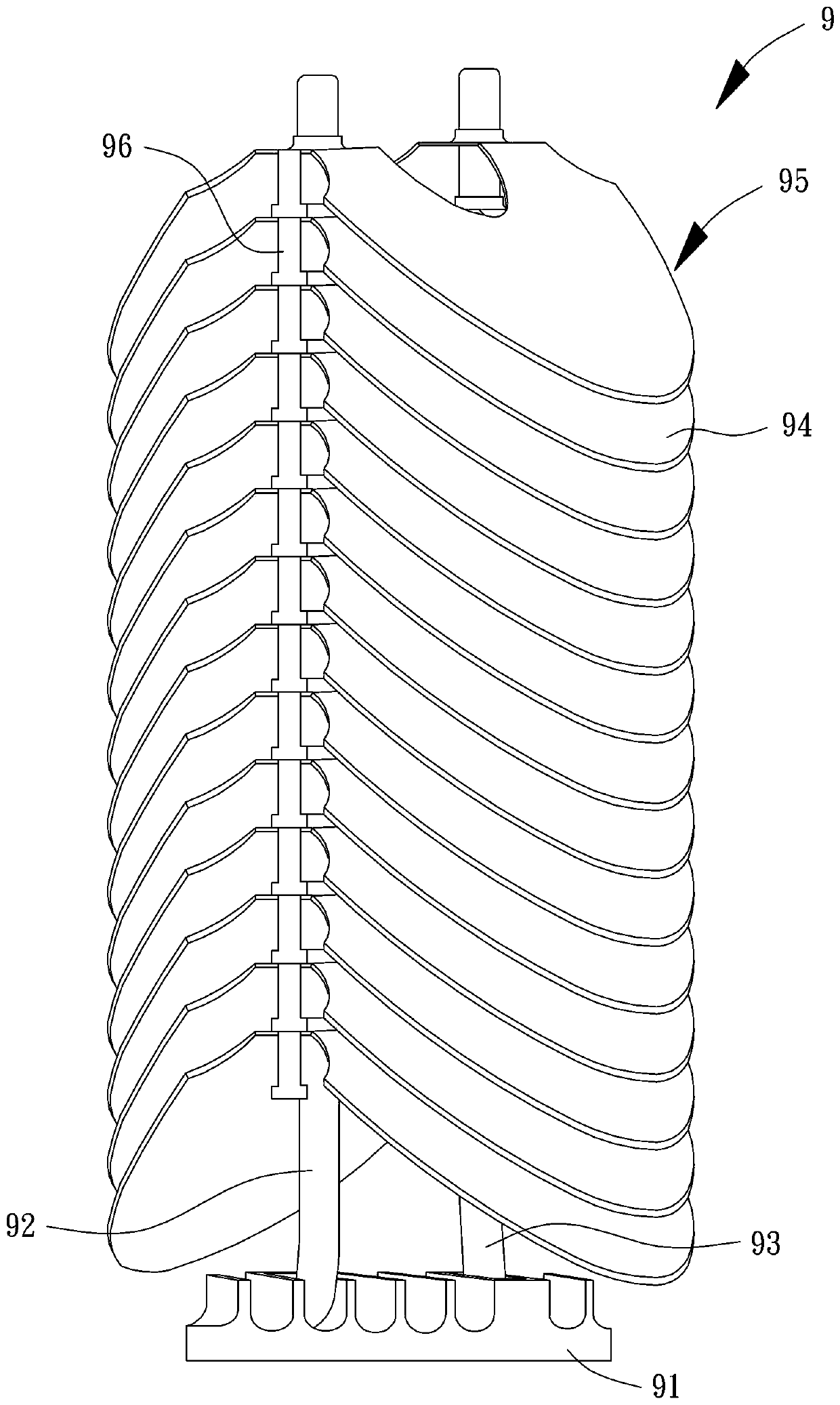

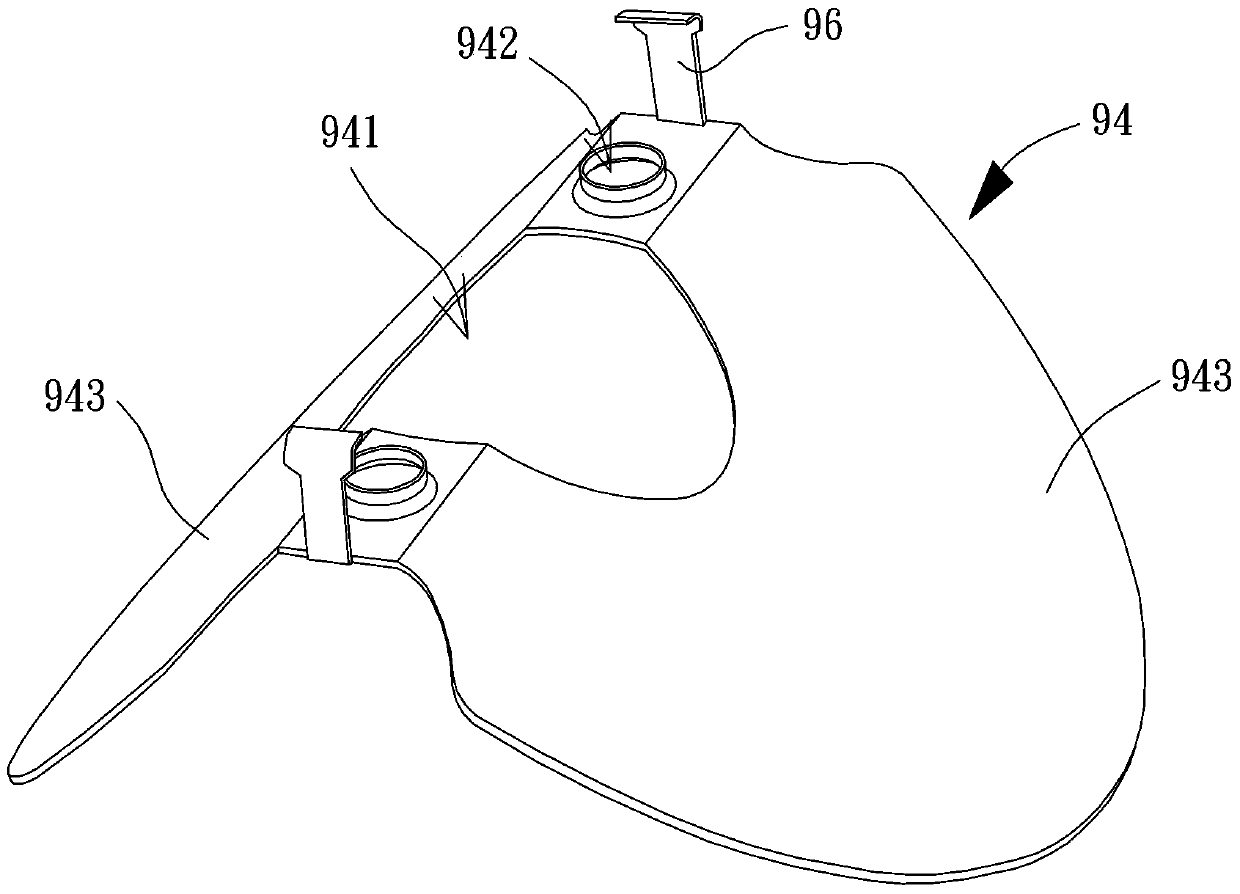

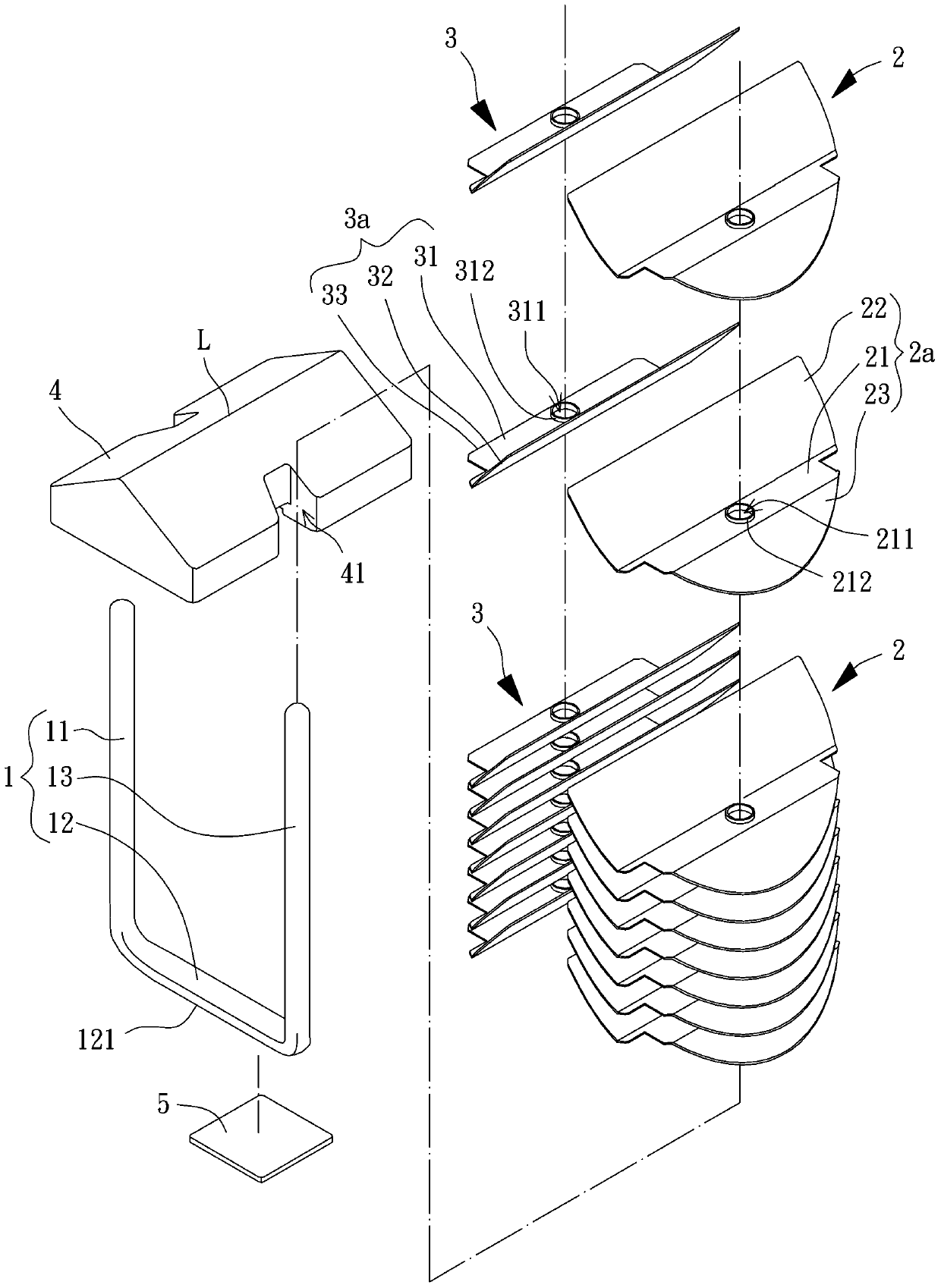

[0056] Please refer to image 3 , 4 , 5, is the first preferred embodiment of the present invention, the heat dissipation module of the present invention generally includes a heat pipe 1, a first heat dissipation component 2 and a second heat dissipation component 3, the first heat dissipation component 2 and the second heat dissipation component The heat dissipation components 3 are respectively serially positioned at two ends of the heat pipe 1 . The heat dissipation module of the present invention can assist a heat source H (for example: an LED lamp) to dissipate heat, so that the heat source H can be maintained at a normal operating temperature.

[0057] The heat pipe 1 is made of a material with high thermal conduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com