Layered process string

A technology of process pipe strings and screens, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc. It can solve the problems that the separate production technology cannot meet the production needs, cannot be carried out smoothly, and interferes with the production of oil wells. The effects of improving single well production and production timeliness, reasonable structure design, and avoiding interlayer interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below with reference to the drawings and embodiments. However, those skilled in the art should know that the present invention is not limited to the specific embodiments listed, as long as it conforms to the spirit of the present invention, it should be included in the protection scope of the present invention.

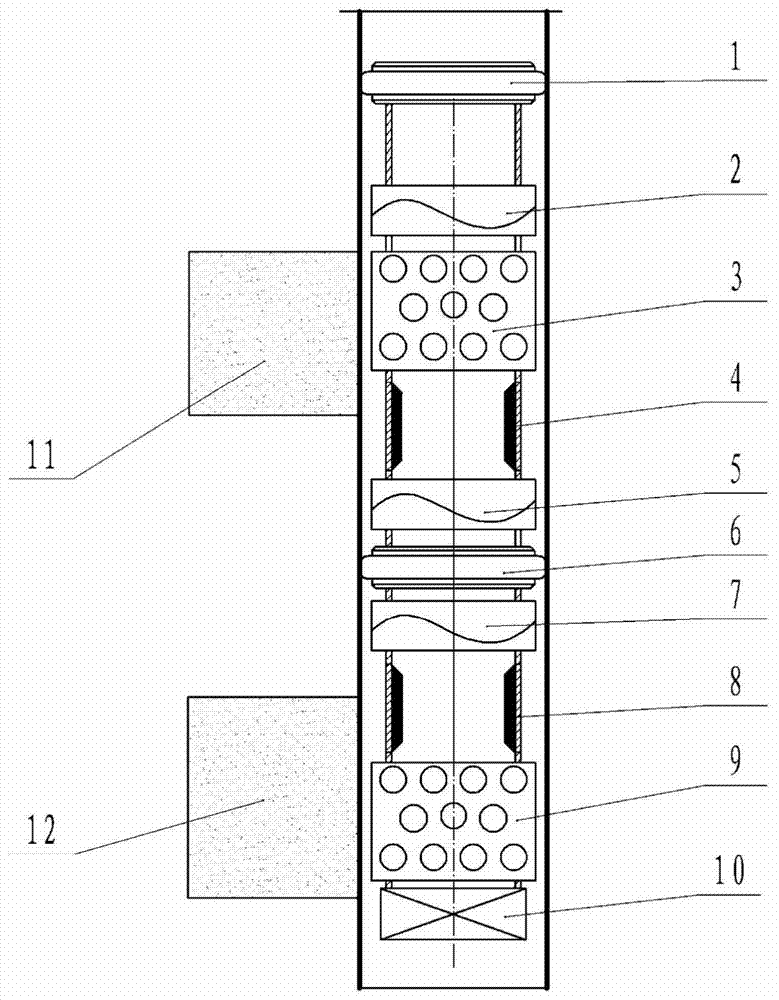

[0009] See attached figure 1 . The layered process pipe string of the present invention includes a packer, a safety joint, a screen, a plug, a tubing, a packer I1, a safety joint I2, a screen I3, a sealing mandrel I4, a safety joint II5, and a packer II6 , The safety joint Ⅲ 7, the sealing mandrel Ⅱ 8, the screen pipe Ⅱ 9, and the plug 10 are fixedly connected through the oil pipe from top to bottom. Packer I1 is located above the upper oil layer 11, and packer II6 is located between the upper oil layer 11 and the lower oil layer 12, and two packers isolate the upper and lower oil layers. The screen Ⅰ3 is located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com