High-filling composite shielding material for radiation mixing fields and preparation method of high-filling composite shielding material

A technology of composite shielding and shielding materials, which is applied in the field of high-filled composite shielding materials for radiation mixed fields and its preparation, can solve the problems of reducing the content of resin substrates, cracks on the outer surface, complex shape and structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

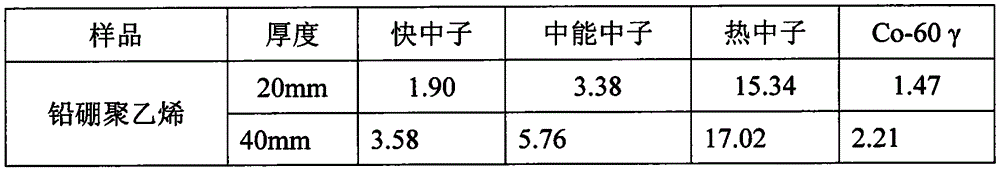

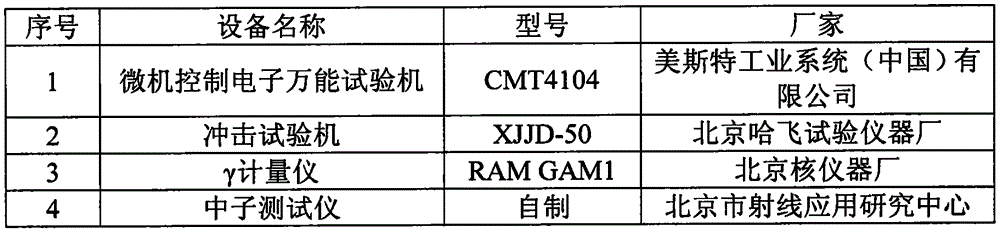

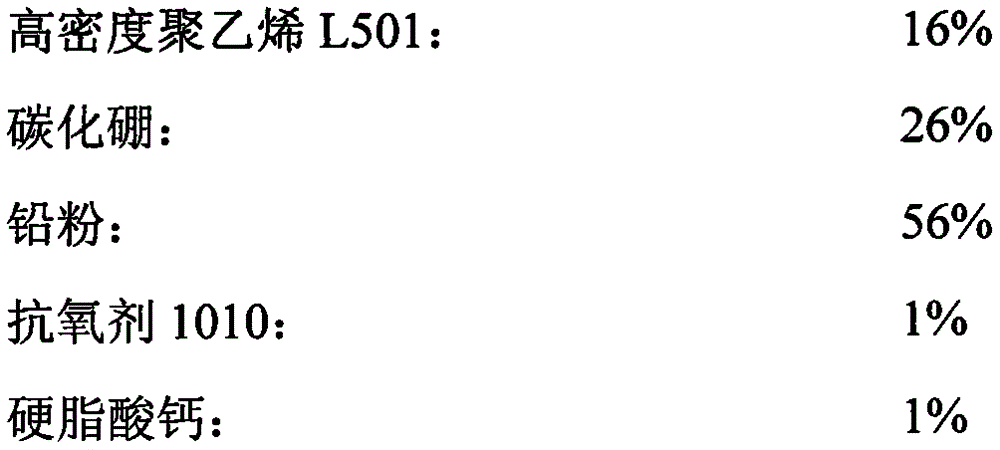

[0034] A high-filling composite shielding material for radiation mixing fields, with high-density polyethylene L501 as the base material, boron carbide as the neutron absorber, lead powder as the gamma ray absorber, supplemented by antioxidant 1010 and calcium stearate, After quantitative weighing, uniform mixing, under certain pressure and temperature field conditions, it is prepared by molding and shaping. Among them, the components in the shielding material are as follows:

[0035] Highly filled composite shielding material for radiation mixing field, the content of each component is calculated by weight percentage:

[0036]

[0037] Its process steps are as follows:

[0038] (1) Mixing

[0039] Quantitatively weigh high-density polyethylene L501, boron carbide and lead powder according to the proportion, first masticate the high-density polyethylene for 15 minutes at 170°C, then add boron carbide, antioxidant 1010 and calcium stearate, and knead for 10 minutes , and f...

Embodiment 2

[0048] A high-filling composite shielding material for radiation mixing fields, with polypropylene as the base material, monomeric boron as the neutron absorber, lead particles as the gamma ray absorber, supplemented by antioxidant 7910, calcium stearate and nano-membrane The de-soil is prepared by quantitative weighing, uniform mixing, and under certain pressure and temperature field conditions, through molding and other processes. Among them, the components of the shielding material are as follows:

[0049] Highly filled composite shielding material for radiation mixing field, the content of each component is calculated by weight percentage:

[0050]

[0051] Its preparation process steps are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com