Smoke gas on-line monitoring system and smoke gas on-line monitoring method

A monitoring system and flue gas technology, applied in the direction of analyzing materials, instruments, etc., can solve the problems of loss of enterprises, cumbersome and complicated processes, large detection errors of analytical instruments, etc., to avoid clogging and detection errors, accurate analysis and detection, and stable flue gas. The effect of flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

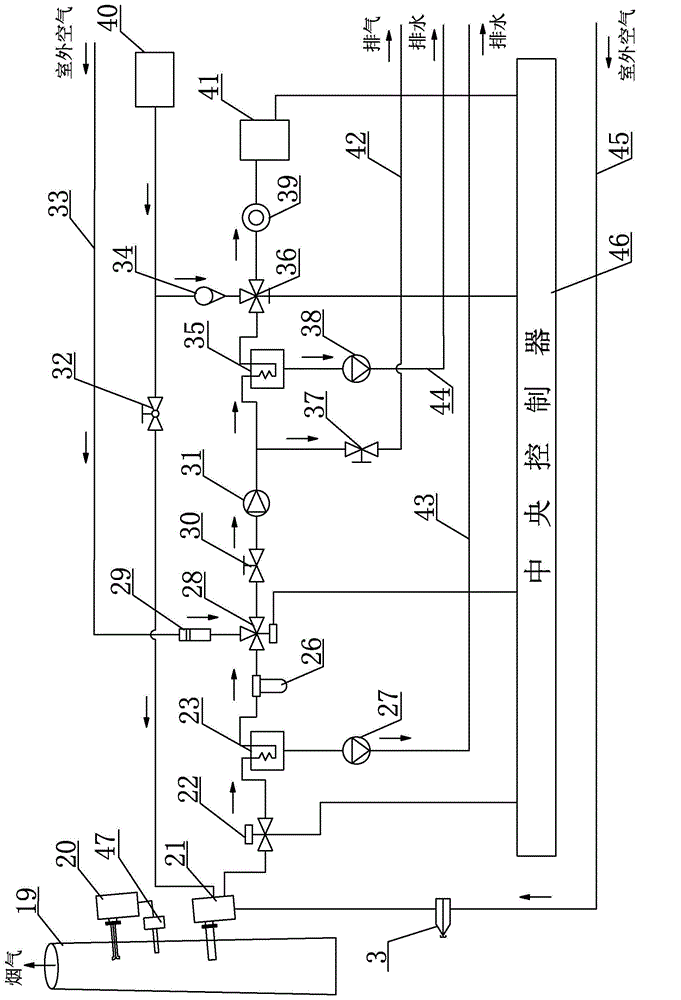

[0032] like figure 1As shown, it is a structural schematic diagram of the flue gas online monitoring system of the present invention, including a central controller 46, a pitot tube flow meter 20, a flue gas sampler 21, a particle monitor 47, a sampler back-purging device, a pitot tube flow meter and The particle monitors share the back-purging device, sampling line and calibration line. The flow velocity measuring end of the pitot tube flow meter 20, the sampling probe of the flue gas sampler 21 and the detection end of the particle monitor 47 are respectively inserted into the chimney 19 of the exhaust gas, and the pitot tube flow meter 20 is connected to the flue gas in the chimney 19. To measure the emission rate, the flue gas sampler 21 collects a certain amount of flue gas and sends it to the multi-component gas analyzer 41 through the sampling pipeline. The multi-component gas analyzer 41 analyzes and detects whether the flue gas discharged from the chimney 19 is up to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com