Method for detecting defects of furnace tube based on magnetostrictive ultrasonic guided wave detection technology

An ultrasonic guided wave and magnetostrictive technology, which is used in the analysis of solids using sonic/ultrasonic/infrasonic waves, and the use of vibrating fluids.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

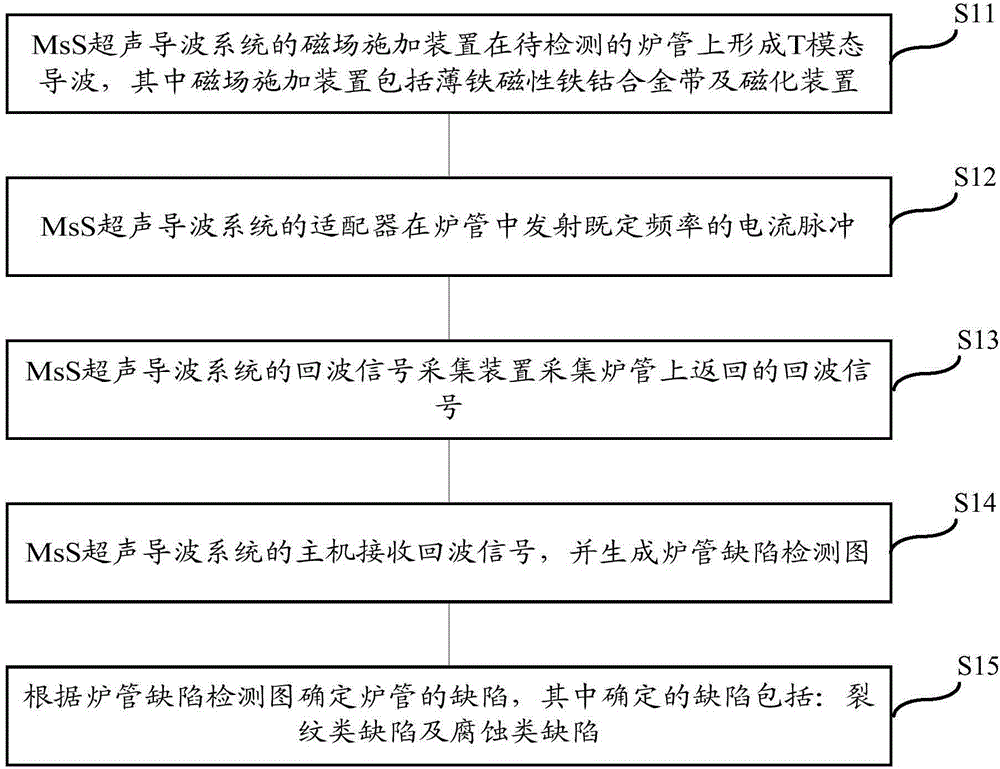

[0025] An embodiment of the present invention provides a method for detecting furnace tube defects based on magnetostrictive ultrasonic guided wave detection technology, such as figure 1 As shown, the main processing steps include:

[0026] Step S11: The magnetic field applying device of the MsS ultrasonic guided wave system forms a T-mode guided wave on the furnace tube to be tested, wherein the magnetic field applying device includes a thin ferromagnetic iron-cobalt alloy strip and a magnetizing device;

[0027] Step S12: the adapter of the MsS ultrasonic guided wave system emits a current pulse of a predetermined frequency in the furnace tube;

[0028] Step S13: the echo signal acquisition device of the MsS ultrasonic guided wave system collects the echo signal returned from the furnace tube;

[0029] Step S14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com