Manganin pressure sensor and device for measuring underwater explosion near-field impact wave pressure

A pressure sensor, underwater explosion technology, applied in the direction of measuring devices, force/torque/power measuring instruments, instruments, etc., to achieve the effect of improving signal-to-noise ratio, improving measurement accuracy, and shortening response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]The sensitive element of the manganese-copper pressure sensor for measuring the near-field shock wave pressure of an underwater explosion is a manganese-copper alloy wire with a resistance value of 50Ω. Studies have shown that although the piezoresistive coefficient of manganese-copper alloy is not high, it is better than PVDF material due to its small temperature coefficient of resistance, and it also has the characteristics of fast response and good linearity, which is very suitable for making ultra-high pressure sensors.

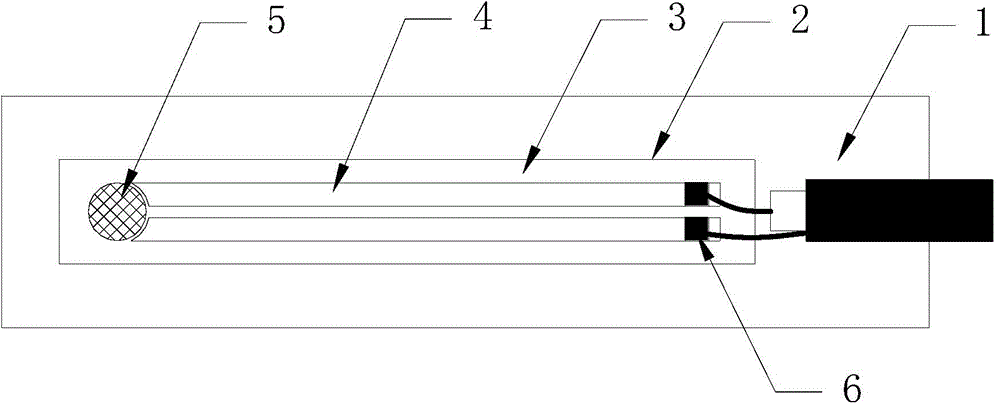

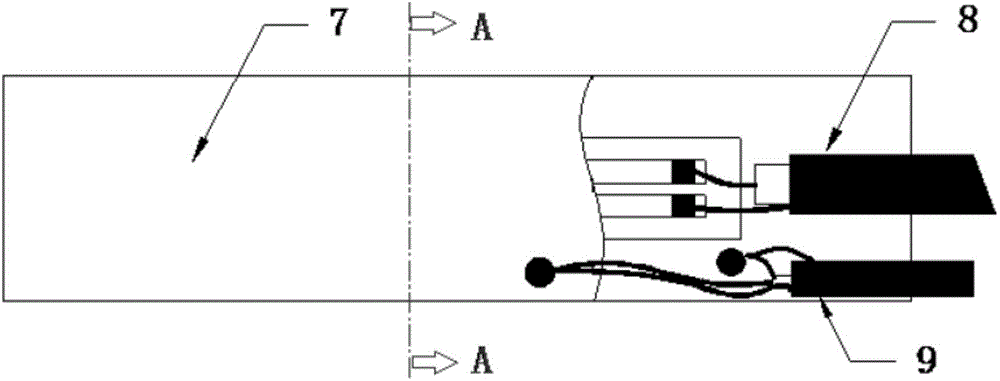

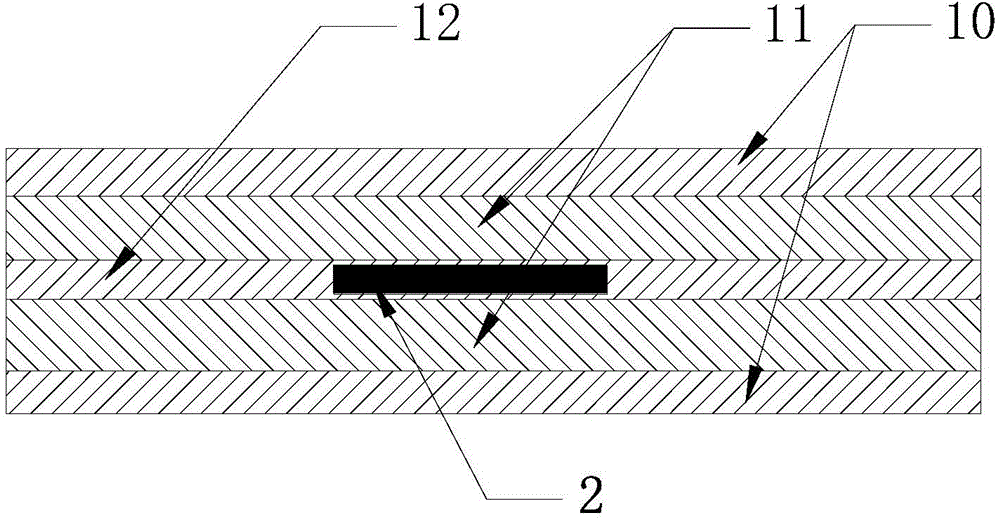

[0037] like Figure 1 to Figure 4 As shown, the present invention is mainly composed of two copper-clad polytetrafluoroethylene sheets and a manganese-copper sensitive element. The sensitive element (2) is sandwiched between the thin plates (1) and (7), and they are connected and sealed by a transparent epoxy potting glue (12). The transparent epoxy potting model HT 6308 is better used Glue connection seal.

[0038] The dimensions of the sensitive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com