Preparation method of graphene-based surface strain sensor

A strain sensor, graphene-based technology, applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measurement devices, etc., can solve the problems of difficult to prepare area thin film, unable to meet health detection, complicated preparation process, etc., to achieve low price, manufacturing The effect of low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

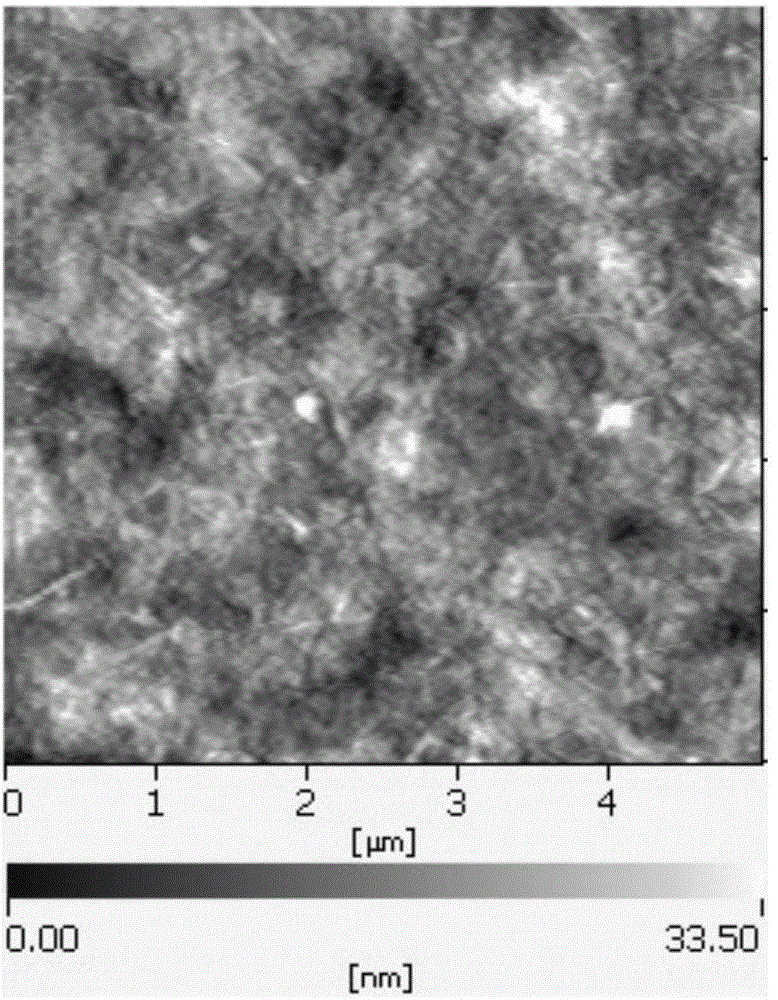

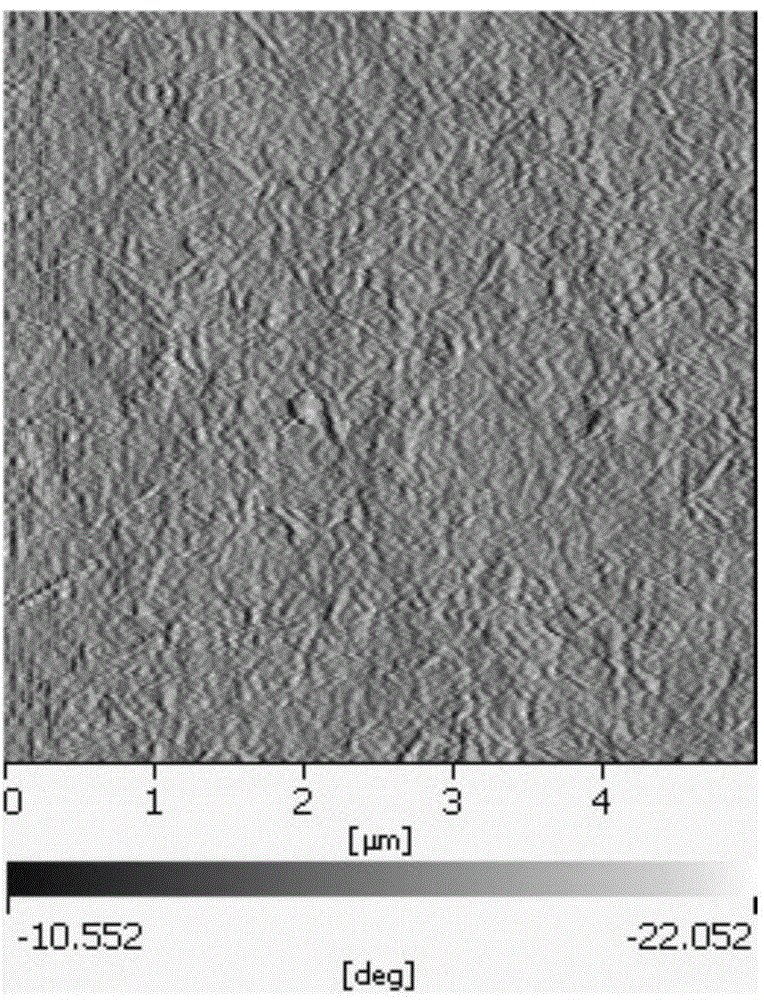

Embodiment 1

[0036] Take 50ml of the 1mg / ml graphene oxide solution, and add 250ml of ethanol thereto. Stably dispersed graphene oxide dispersions were prepared in water / ethanol solutions. Ultrasound for a while, take 6ml of uniform solution and add it to the airbrush spray can. The polytetrafluoroethylene substrate was cleaned, then dried, and placed on a heating platform to raise the temperature to 100°C. At this time, use a spray pen connected with an air pump to spray the above solution on the polytetrafluoroethylene substrate with an area of 2×10 cm, and the spray distance is about 5 cm. Graphene oxide films (such as Figure 1 ~ Figure 4 shown), and then utilize HI acid to reduce the film to form a graphene film. At the two ends of the graphene film, connect two copper electrodes with conductive glue, and connect an ohmmeter between the two electrodes; then on the graphene film Continue to spray a layer of styrene-acrylic emulsion to form a polymer latex film, that is, to obtain ...

Embodiment 2

[0038] A 0.2 mg / ml graphene oxide solution was prepared using ethanol solution as a dispersion medium. Ultrasound for a while, take 6ml of uniform solution and add it to the airbrush spray can. The silica gel substrate is cleaned and then dried. At this time, use a spray pen connected with an air pump to spray the above solution on the silica gel substrate with an area of 2×10 cm, and the spray distance is about 5 cm. Prepared a graphene oxide film, and then used HI acid to reduce the film to form a graphene film. At both ends of the graphene film, connect two copper electrodes with conductive glue, and connect an ohmmeter between the two electrodes; then spray a layer of Styrene emulsion. After the emulsion film was dried, the sensing performance test was carried out.

[0039] Among them, the sensitivity index Gauge factor (GF) is about 5 (GF=(R-R 0 ) / R 0 ε, where R represents the resistance before deformation, R 0 Indicates the resistance after deformation, ε indicat...

Embodiment 3

[0041]A 0.2 mg / ml graphene oxide solution was prepared using ethanol solution as a dispersion medium. Add carbon nanotubes wherein, make graphene oxide: the mass ratio of carbon nanotubes is 5: 1, after ultrasonic 30min, get 6ml this solution, add the titanium dioxide solution of 0.5mg / ml wherein (particle diameter: 5nm, sharp titanium ore) 2ml. At this time, use a spray pen connected with an air pump to spray the above solution on the polytetrafluoroethylene substrate with an area of 2×10 cm, and the spray distance is about 5 cm. A graphene oxide film / carbon nanotube / titanium dioxide composite film (such as Image 6 , Figure 7 shown). Irradiate under ultraviolet light for 10h, (wherein the ultraviolet lamp is 175W, and the sample is 15cm away from the lamp tube) to reduce to form a graphene film. At the two ends of the graphene film, connect two copper electrodes with conductive glue. Connect the ohmmeter between the electrodes; then spray a layer of styrene-acrylic em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com