Powder sintering device

A sintering device and powder technology, applied in structural parts, lighting and heating equipment, furnace components, etc., can solve the problems of unbalanced powder sintering, large differences in powder sintering temperature, and low product yield, etc., and achieve sintering. The effect of uniform temperature, uniform mixing, increased collision probability and contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The powder sintering device provided by the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

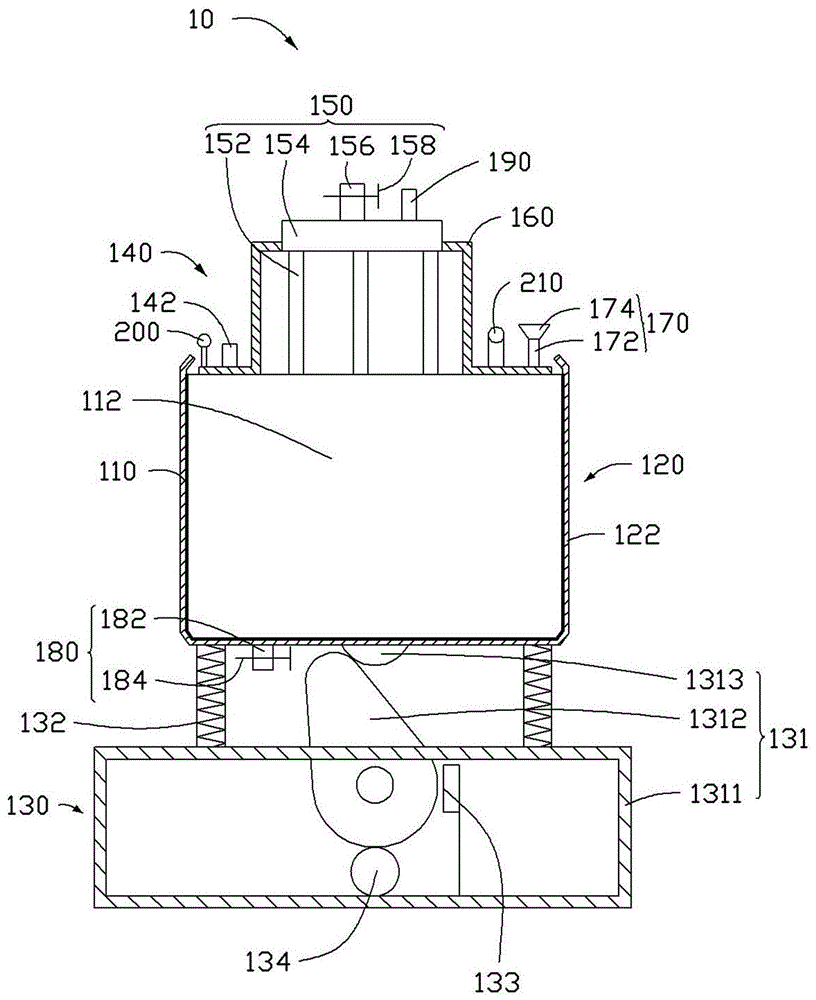

[0012] see figure 1 , The present invention provides a powder sintering device 10, comprising a furnace body 110, a first heating system 120, a vibration system 130, an air intake system 140, an exhaust system 150, a second heating system 160, a A feeding system 170 and a discharging system 180 .

[0013] The structure of the furnace body 110 is not limited, preferably, the furnace body 110 is a hollow columnar structure. The hollow columnar structure may be a hollow cylinder or prism. The prism may be a quadrangular prism, a pentagonal prism, or a hexagonal prism. In this embodiment, the furnace body 110 is a hollow cylindrical structure, and the furnace body 110 has a closed reaction chamber 112 . The material of the furnace body 110 is selected from high temperature resistant materials. Fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com