Method for assembling inflatable single-tube shock absorber

An assembly method and shock absorber technology, which are applied in the manufacture of gas-liquid shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve the problems of unsatisfactory product assembly quality, affecting product quality, and large equipment investment, etc. To achieve the effect of reducing equipment investment, reducing defect rate and unnecessary production loss, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

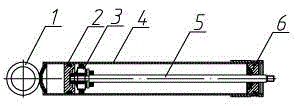

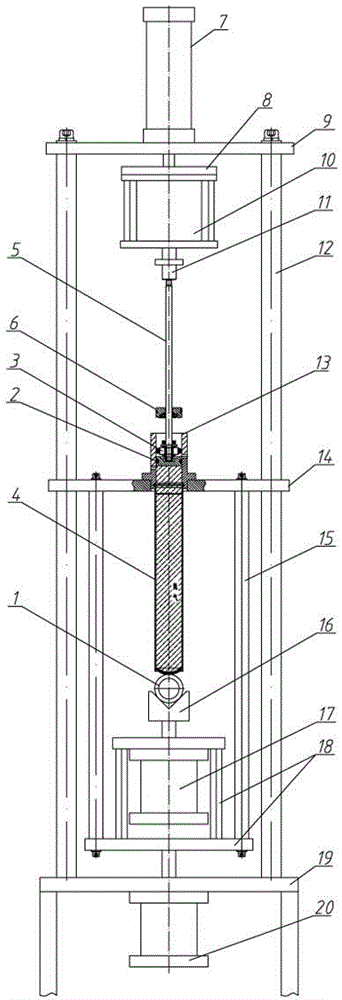

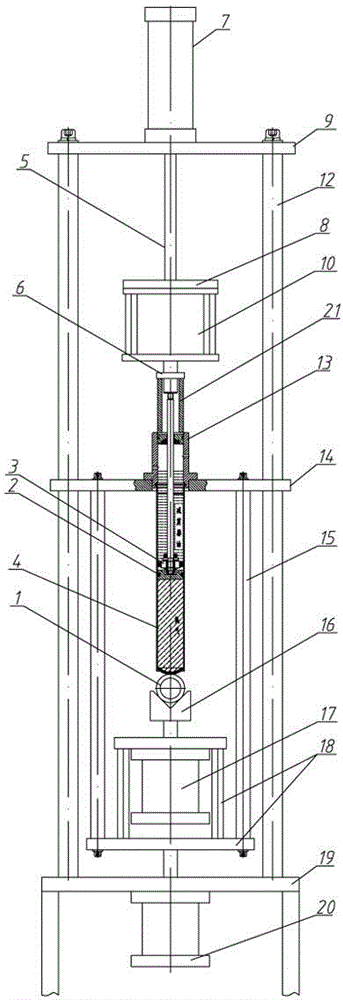

[0017] see figure 1 , which is a typical assembled structure of an inflatable single cylinder shock absorber, which consists of a lifting ring 1, a floating piston 2, a piston subassembly 3, an oil storage cylinder subassembly 4, a connecting rod 5, and a guide oil seal subassembly 6 assembled, the assembly process method is as follows: firstly, a special assembly equipment is made, which has a base 19, four columns 12 are installed on the base 19, upper formwork 9 is fixedly installed on the top of the four columns 12, and four The middle section of the column 12 is equipped with a sliding formwork 14, and the middle part of the sliding formwork 14 is equipped with a multifunctional guide sleeve 13. On the multifunctional guide sleeve 13, there are upper and lower misaligned oil filling ports and air charging ports. The lower end of the multifunctional guide sleeve 13 Also be provided with sealing ring; The upper fixed cylinder 7 is installed in the middle part of upper formw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com