Pumping unit indicator diagram liquid production capacity measurement technology

A liquid production and pumping unit technology, which is applied in measurement, wellbore/well components, earth-moving drilling, etc., can solve the problems of low measurement accuracy, difficult operation, manual measurement, etc. Overcome high cost and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

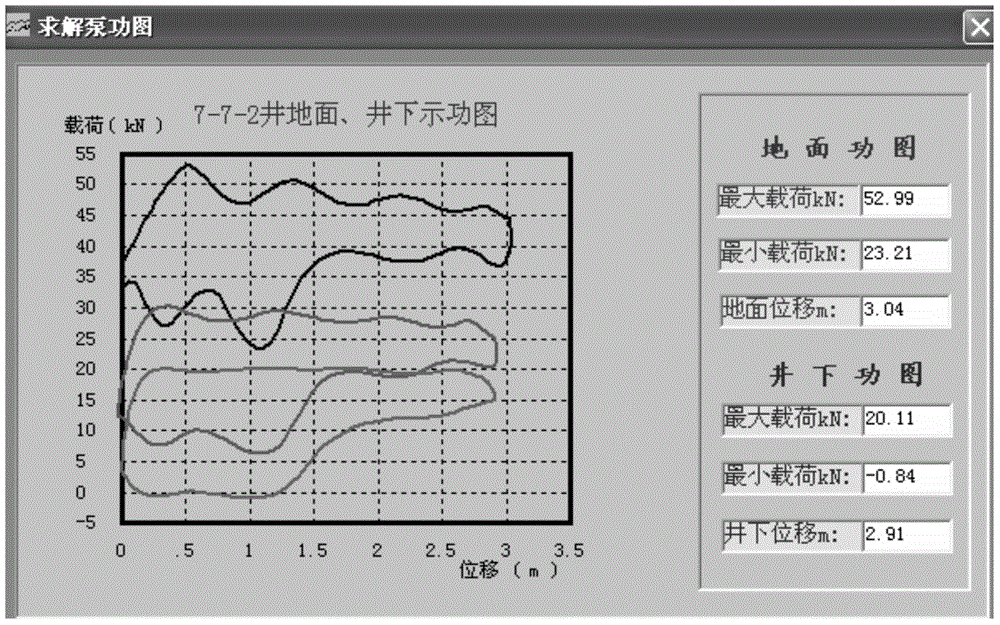

[0058] According to an embodiment of the present invention, such as Figure 1-Figure 13 As shown, the fluid production measurement technology of the pumping unit power diagram method is provided, which can calculate the fluid production of the pumping well in the oil field.

[0059] The technical solution of the present invention mainly includes several large components, namely: a module for converting an indicator diagram to a pump diagram, a data management module, an analysis and diagnosis module, and a liquid volume calculation module.

[0060] Compared with the prior art, the technical solution of the present invention has at least the following characteristics...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com