A kind of kapok fiber processing technology

A kapok fiber and processing technology, which is applied in fiber treatment, chemical post-treatment of fibers, plant fibers, etc., can solve the problems of low elongation at break, high unevenness of kapok fiber, and poor spinnability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

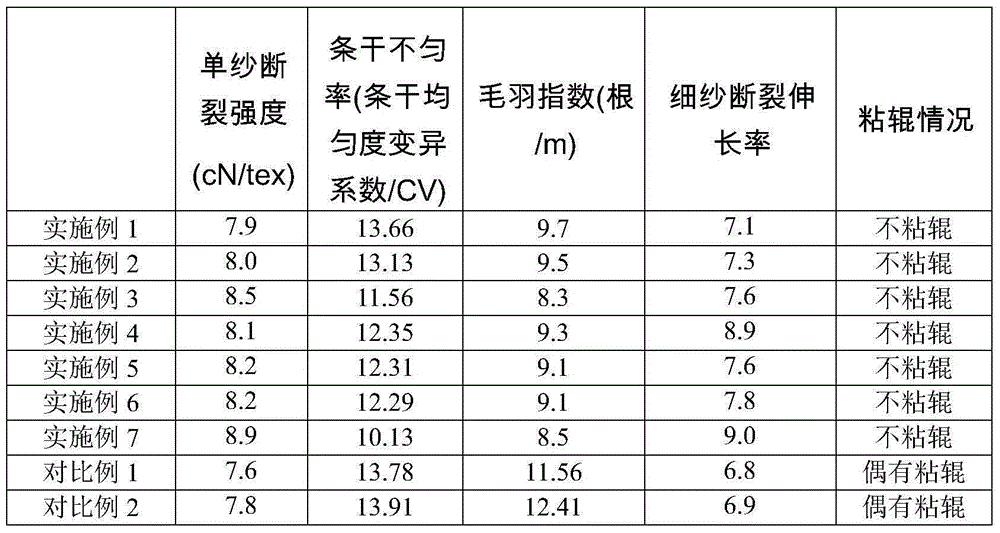

Examples

Embodiment 1

[0031] The kapok fiber processing technology described in the present embodiment, comprises the steps:

[0032] (1) Get the kapok fiber for use, and carry out opening and impurity removal to the kapok fiber; this step can be completed by any prior art opening and impurity removal process, and can be processed by an opener during opening , when removing impurities, fiber cleaners can be used for processing;

[0033] (2) Continuously input 360kg of kapok fibers after opening into the closed cotton warehouse through the pipeline, and continuously spray the first auxiliary agent in the cotton warehouse when the kapok fibers are input into the closed cotton warehouse, and when the kapok fibers are filled with the cotton warehouse , stop spraying the first auxiliary agent. During this process, it is necessary to ensure that the amount of the first auxiliary agent sprayed is 180kg, and then set the temperature of the cotton warehouse to 43°C for 5 hours of simmering;

[0034] The fi...

Embodiment 2

[0042]The kapok fiber processing technology described in the present embodiment, comprises the steps:

[0043] (1) Get the kapok fiber for use, and carry out opening and impurity removal to the kapok fiber; this step can be completed by any prior art opening and impurity removal process, and can be processed by an opener during opening , when removing impurities, fiber cleaners can be used for processing;

[0044] (2) 425 kg of kapok fibers after opening are continuously input into the closed cotton warehouse through the pipeline, and the first auxiliary agent is continuously sprayed into the cotton warehouse when the kapok fibers are input into the closed cotton warehouse, and when the kapok fibers are filled with the cotton warehouse , stop spraying the first auxiliary agent. During this process, it is necessary to ensure that the amount of the first auxiliary agent sprayed is 170kg, and then set the temperature of the cotton warehouse to 45°C for 6 hours of simmering;

[0...

Embodiment 3

[0053] The kapok fiber processing technology described in the present embodiment, comprises the steps:

[0054] (1) Get the kapok fiber for use, and carry out opening and impurity removal to the kapok fiber; this step can be completed by any prior art opening and impurity removal process, and can be processed by an opener during opening , when removing impurities, fiber cleaners can be used for processing;

[0055] (2) Continuously input 550kg of kapok fiber after opening into the closed cotton warehouse through the pipeline, and continuously spray the first auxiliary agent in the cotton warehouse when the kapok fiber is input into the closed cotton warehouse, and when the kapok fiber is full of the cotton warehouse , stop spraying the first auxiliary agent. During this process, it is necessary to ensure that the amount of the first auxiliary agent sprayed is 165kg, and then set the temperature of the cotton warehouse to 46°C for 12 hours of simmering;

[0056] The first auxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com