Electromagnetic shielding coating for heat-shrinkable tube and preparation method thereof

An electromagnetic shielding coating, a practical technology, applied in the direction of conductive coatings, coatings, etc., can solve the problems of resin difficult to adhere firmly, weak boundary layer, low surface energy, etc., and achieve the effect of light weight, firm adhesion and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

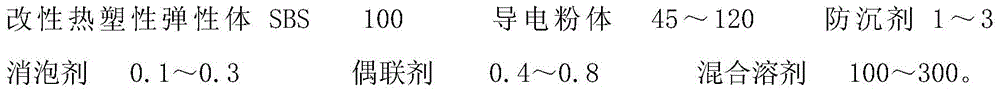

Method used

Image

Examples

Embodiment 1

[0029] a. Graft modification of thermoplastic elastomer SBS:

[0030] ——Take 200 parts by mass of mixed solvent (the mass ratio of 120# solvent gasoline and toluene is 8:1) in the reactor, heat up to 60°C, and add 100 parts by mass of thermoplastic elastomer SBS (YH-791, S / B is 30 / 70), dissolves completely, obtains solution; Then

[0031] ——Raise the temperature of the dissolving solution to 68°C, add 6 parts by mass of toluene solution containing 10% dibenzoyl peroxide, feed nitrogen, heat up to 78°C, stir, and then mix 0.6 parts by mass of dibenzoyl peroxide with 40 parts by mass of methyl methacrylate and 25 parts by mass of butyl acrylate were mixed and dropped into the reactor for about 20 minutes. After 100 minutes of reaction, 12 parts by mass of dibenzoyl peroxide containing 10% Toluene solution.

[0032] ——Insulation reaction 4h, add 0.3 mass parts polymerization inhibitor hydroquinone, stir again 30min, be down to room temperature, add 0.4 mass parts antioxidant 1...

Embodiment 2

[0036] a. Graft modification of thermoplastic elastomer SBS:

[0037] ——Take 300 parts by mass of mixed solvent (the mass ratio of 120# solvent gasoline and toluene is 2:1) in the reactor, heat up to 50°C, and add 100 parts by mass of thermoplastic elastomer SBS (YH-792, S / B is 40 / 60), dissolves completely, obtains solution; Then

[0038] ——Raise the temperature of the dissolving solution to 75°C, add 4 parts by mass of toluene solution containing 10% dibenzoyl peroxide, feed nitrogen, heat up to 85°C, stir, and then mix 0.4 parts by mass of dibenzoyl peroxide with Mix 55 parts by mass of methyl methacrylate and 10 parts by mass of butyl acrylate and drop them into the reactor for about 40 minutes. After reacting for 80 minutes, add 8 parts by mass of dibenzoyl peroxide containing 10% Toluene solution.

[0039] ——Insulation reaction 3h, add 0.6 mass parts inhibitor hydroquinone, stir again 15min, be down to room temperature, add 0.8 mass parts antioxidant 1010, supplement m...

Embodiment 3

[0043] a. Graft modification of thermoplastic elastomer SBS:

[0044] ——Take 250 parts by mass of mixed solvent (the mass ratio of 120# solvent gasoline and toluene is 5:1) in the reactor, heat up to 55°C, and add 100 parts by mass of thermoplastic elastomer SBS (YH-791, YH- 792 each 50g), dissolve completely, obtain solution; Then

[0045] ——Raise the temperature of the dissolving solution to 70°C, add 5 parts by mass of toluene solution containing 10% dibenzoyl peroxide, feed nitrogen, heat up to 80°C, stir, and then mix 0.5 parts by mass of dibenzoyl peroxide with 48 parts by mass of methyl methacrylate and 18 parts by mass of butyl acrylate were mixed and dropped into the reactor for about 30 minutes. After reacting for 90 minutes, 10 parts by mass of dibenzoyl peroxide containing 10% Toluene solution.

[0046] - heat preservation reaction 3.5h, add 0.4 mass parts polymerization inhibitor hydroquinone, stir again 20min, be down to room temperature, add 0.6 mass parts ant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com