New preparation process of tasimeltion intermediate

A technology of tasimelteon and preparation process, which is applied in the field of preparation of synthesizing tasimelteon intermediates, and can solve problems such as inability to enlarge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

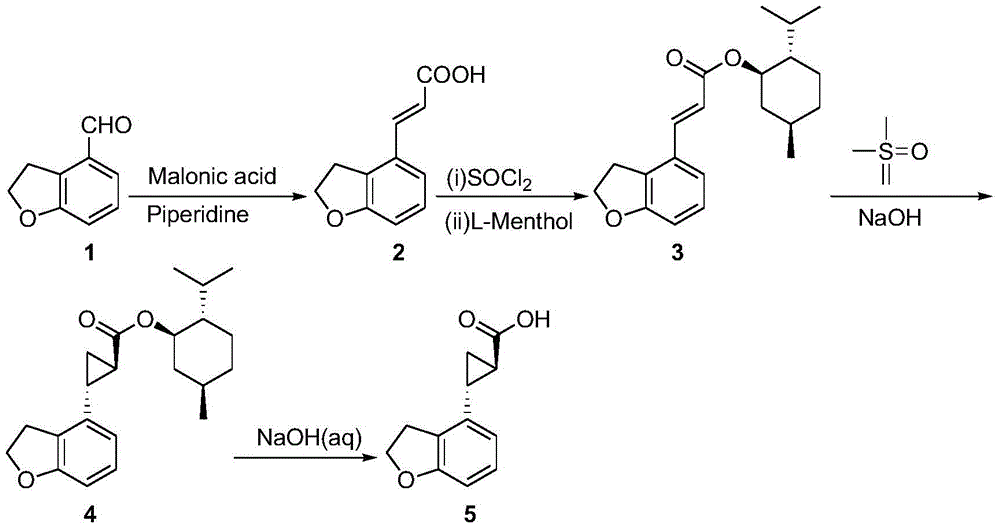

Method used

Image

Examples

Embodiment 1

[0021] (compound 2 Synthesis)

[0022] Add pyridine (1.3Kg) and piperidine (50g) into a 10L four-neck flask equipped with a thermometer, mechanical stirring, constant pressure dropping funnel, and tail gas absorption device, stir and heat up to 90-100°C, slowly add 2,3 - Dihydrobenzofuran-4-carbaldehyde (1.0 Kg), then malonic acid (1.5 Kg) was added. Stirring was continued at 90-100°C for 4 hours; then water (4.0 L) was added, and a pyridine / water mixture (2.5 L) was evaporated from the reaction flask under reduced pressure. After cooling to room temperature, the pH of the reaction solution was adjusted to 1 with 37% concentrated hydrochloric acid (4.5Kg), and a large amount of solids were precipitated. Filter, wash twice with 1% hydrochloric acid (3 L each time), and dry under vacuum at 40-50°C to obtain 2,3-dihydrobenzofuran-4-acrylic acid (1.1Kg), with a yield of 85% and a purity of 98%.

[0023] (compound 3 Synthesis)

[0024] compound 2 (1.0Kg), a mixture of toluene...

Embodiment 2

[0032] (compound 2 Synthesis)

[0033] Add pyridine (1.3Kg) and piperidine (50g) into a 10L four-neck flask equipped with a thermometer, mechanical stirring, constant pressure dropping funnel, and tail gas absorption device, stir and heat up to 90-100°C, slowly add 2,3 -Dihydrobenzofuran-4-carbaldehyde (1.0 Kg), then malonic acid (1.8 Kg) was added. Stirring was continued at 90-100°C for 4 hours; then water (4.0 L) was added, and a pyridine / water mixture (2.5 L) was evaporated from the reaction flask under reduced pressure. After cooling to room temperature, the pH of the reaction solution was adjusted to 1 with 37% concentrated hydrochloric acid (4.5Kg), and a large amount of solids were precipitated. Filter, wash twice with 1% hydrochloric acid (3 L each time), and dry under vacuum at 40-50°C to obtain the product (1.2Kg), with a yield of 93% and a purity of 98%.

[0034] (compound 3 Synthesis)

[0035] compound 2 (1.0Kg), a mixture of toluene (1.0kg) and pyridine (30g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com