Preparation method of high-thermal conductivity graphene-Sn-Ag composite brazing filler metal

A technology of high thermal conductivity graphite and composite brazing filler metal, applied in manufacturing tools, welding equipment, metal processing equipment, etc., can solve problems such as graphene floating, improve wettability and thermal conductivity, good brazing and service performance , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

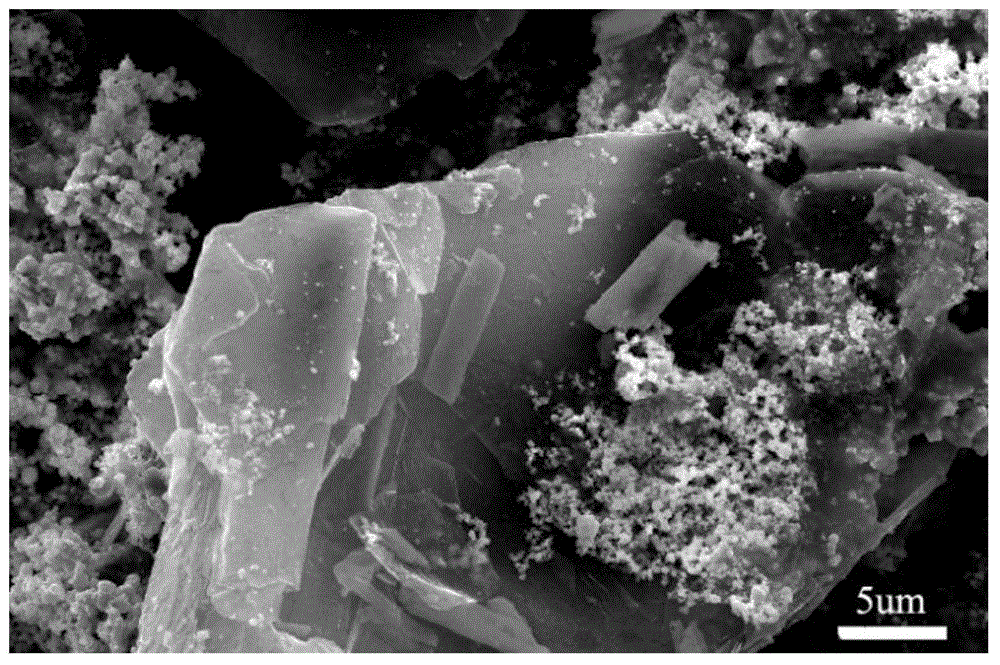

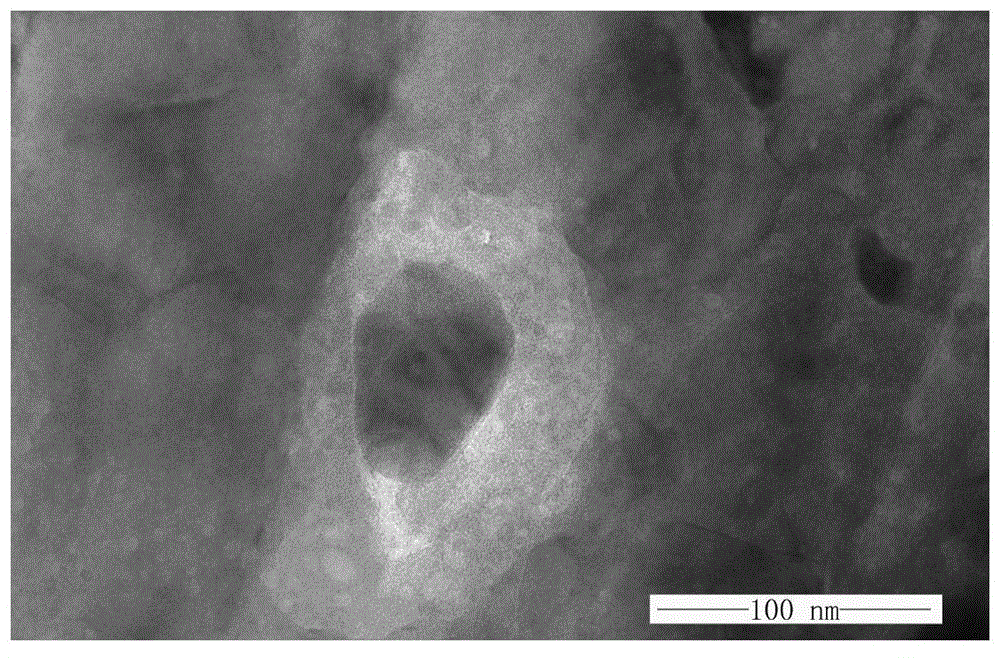

[0020] Specific embodiment one: In this embodiment, a kind of high thermal conductivity graphene--Sn-Ag series composite solder is composed of metal-coated graphene and Sn-Ag series solder; the high thermal conductivity graphene--Sn-Ag series composite The mass fraction of metal-coated graphene in the solder is 0.1%~1%; when the lead-free solder is Sn-Ag-Cu, Sn-Ag-Cu-Bi, Sn-Bi-Ag-Cu alloy The metal-coated graphene is silver-coated graphene or copper-coated graphene; when the lead-free solder is a Sn-Ag alloy, the metal-coated graphene is silver-coated graphene.

[0021] In this embodiment, graphene is used as a reinforcing phase, and its excellent mechanical, electrical and thermal properties are used to improve the performance of the lead-free solder prepared in the prior art.

[0022] This embodiment adopts graphene metal plating, which reduces the density difference between graphene and lead-free solder, and solves the problem of graphene floating and agglomeration caused b...

specific Embodiment approach 2

[0024]Embodiment 2: This embodiment differs from Embodiment 1 in that: the mass fraction of metal-coated graphene in the high thermal conductivity graphene-Sn-Ag composite solder is 0.2%. Others are the same as the first embodiment.

specific Embodiment approach 3

[0025] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the mass fraction of metal-coated graphene in the high thermal conductivity graphene-Sn-Ag composite solder is 0.4%. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com