Offline rapid arc-aligning method for movable segment of arc-shaped billet continuous casting machine

A billet continuous casting and movable section technology, applied in the field of metallurgical rolling, can solve problems such as difficult to meet high quality, high reliability, slow arc alignment speed, high investment cost, etc., to achieve improved stability and slab quality, and convenient Effect of arc alignment and reduction of steel breakout accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

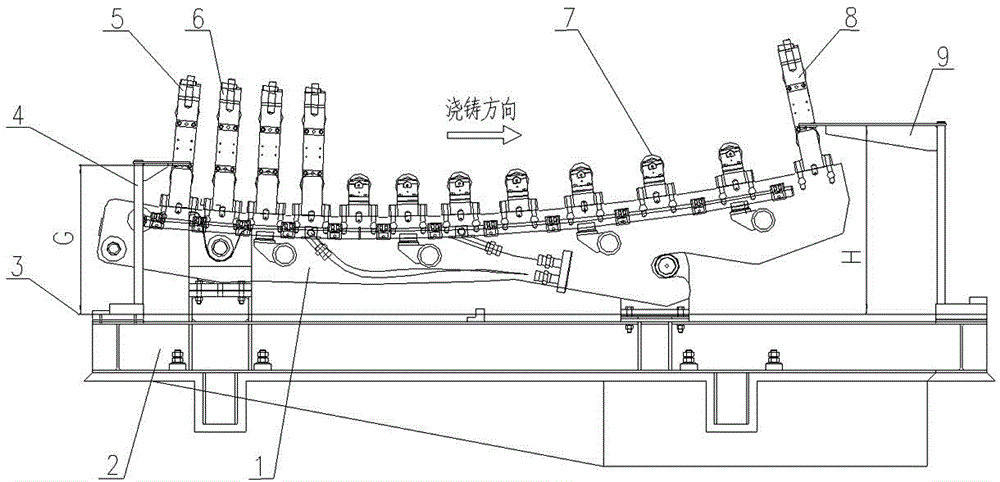

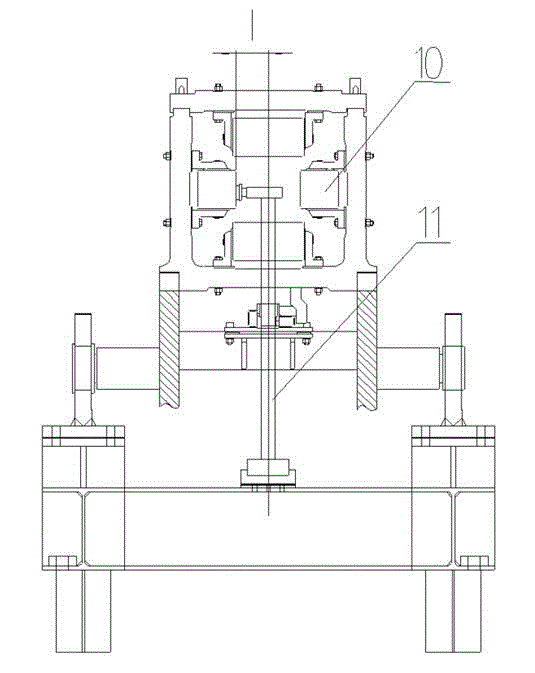

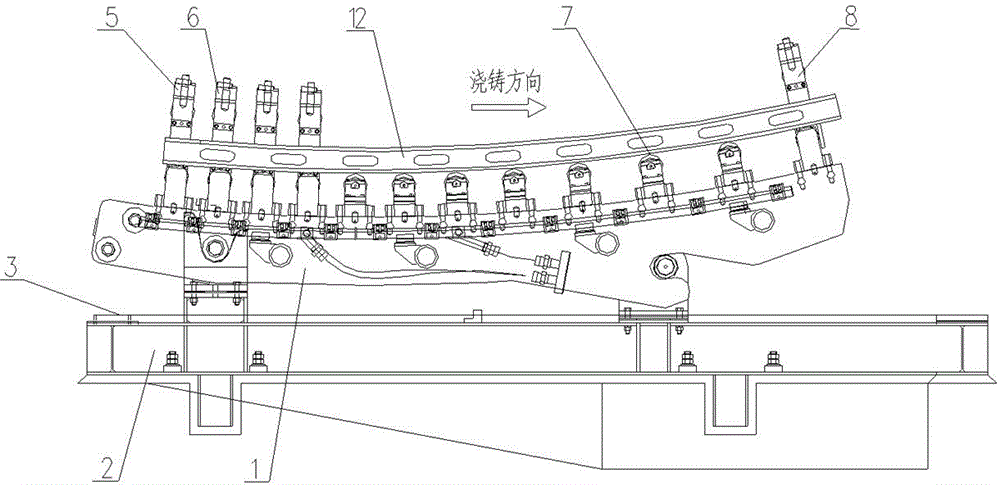

[0042]Take the arc alignment of the 230×230mm section and the offline movable section of the R12m billet continuous casting machine in the steelmaking plant of Kunming Iron and Steel New District as an example. The off-line arc adjustment method of different sections of other arc-shaped billet continuous casting machines can be deduced by analogy.

[0043] Tools and materials (unit: mm): two-point inner diameter micrometer (50~600mm), outer diameter micrometer (0~25mm), feeler gauge 200A20 type and arc alignment template, etc. The arc alignment template includes: 1 arc alignment template, see image 3 ; Measuring tools Ⅰ, Ⅱ and Ⅲ 1 piece each; Measuring plug Ⅰ, Ⅱ and Ⅲ 1 piece each; Among them, measuring tools Ⅰ and Ⅱ are special height gauges, and measuring tool Ⅲ can measure the center distance of side rollers by replacing the measuring plug. There are 4 types of copper gaskets that may be used for arc adjustment: 0.02, 0.05, 0.10, and 0.20 pieces; Q235-A arc gaskets have 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com