Factory culturing pond bottom particle washing and recovering device

A technology for purifying particles and recycling devices, applied in fish farming, application, animal husbandry, etc., can solve the problems of complicated construction, high cost, unsatisfactory sterilization effect, etc., and achieve the effect of less manual intervention and prevention of dirt accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

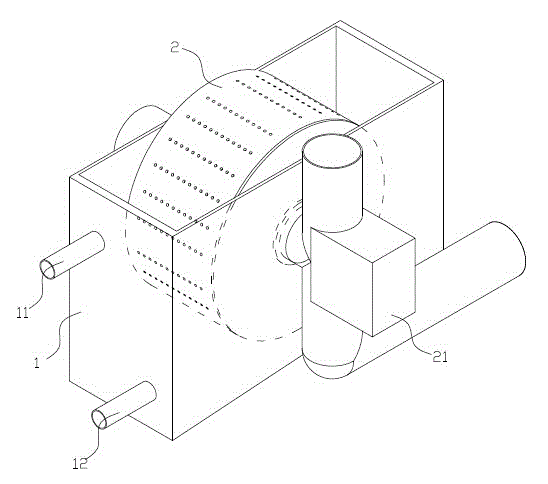

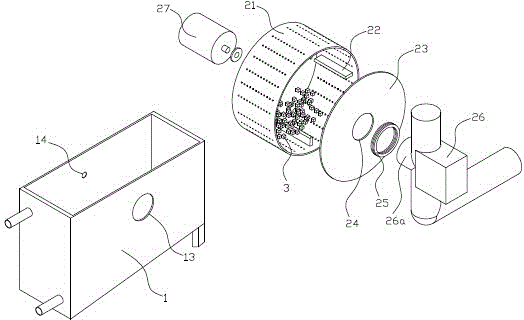

[0011] Example: refer to Figure 1 to Figure 2 A device for cleaning and recovering particles from the bottom of industrialized breeding ponds, including a water storage tank 1 having a water inlet pipe 11 and an outlet pipe 12, wherein: the water storage tank 1 is provided with a drum cleaning assembly 2 that can mechanically clean the dirt adsorption base; Near the side of the water tank 1 is provided a three-way valve 26 that can inject water into and discharge the drum cleaning assembly 2; the drum cleaning assembly 2 is connected with a motor 27; The dirt adsorption base absorbs organic debris, feces, protein and other dirt at the bottom of the water body of the culture pond, and then passes through the pipeline through the three-way valve 26 of the water storage tank 1, and is discharged into the drum cleaning assembly 2 from the interface port 26a. The motor 27 drives the rolling of the drum cleaning assembly 2 for physical cleaning, while the drum cleaning assembly 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com