Sleeve-type yarn unwinding roller

A yarn roller and sleeve technology, which is applied in the field of yarn release rollers, can solve problems such as easy accumulation of dust, and achieve the effects of preventing dirt accumulation, saving costs, and improving efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

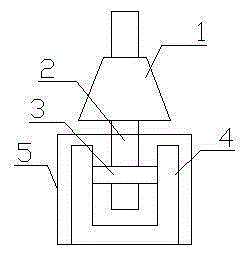

[0009] Such as figure 1 It is a schematic diagram of the structure of the present invention. The sleeve-type yarn unwinding roller includes a roller 1, a roller shaft 2, a bearing 3 and a fixed seat 4. The roller shaft 2 is placed in the roller 1, and the bottom end of the roller shaft 2 is placed in the bearing 3. ring, the fixed seat 4 is fixedly connected with the outer ring of the bearing 3, the fixed seat 4 is sleeved in the glass cylinder 5, and the roller shaft 2 passes through the glass cylinder 5.

[0010] When the glass tube 5 is sleeved on the fixed seat 4, the external dirt is isolated on the glass tube 5, and the glass tube 5 can prevent being corroded by the dirt and prolong the service life. Internal dirt accumulation saves cost and improves efficacy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com