Preparation method and application of spherical lithium ferrite material/carbon cathode material composite

A cathode material and composite technology, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of low lithium ion diffusion coefficient, low electronic conductivity, and limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

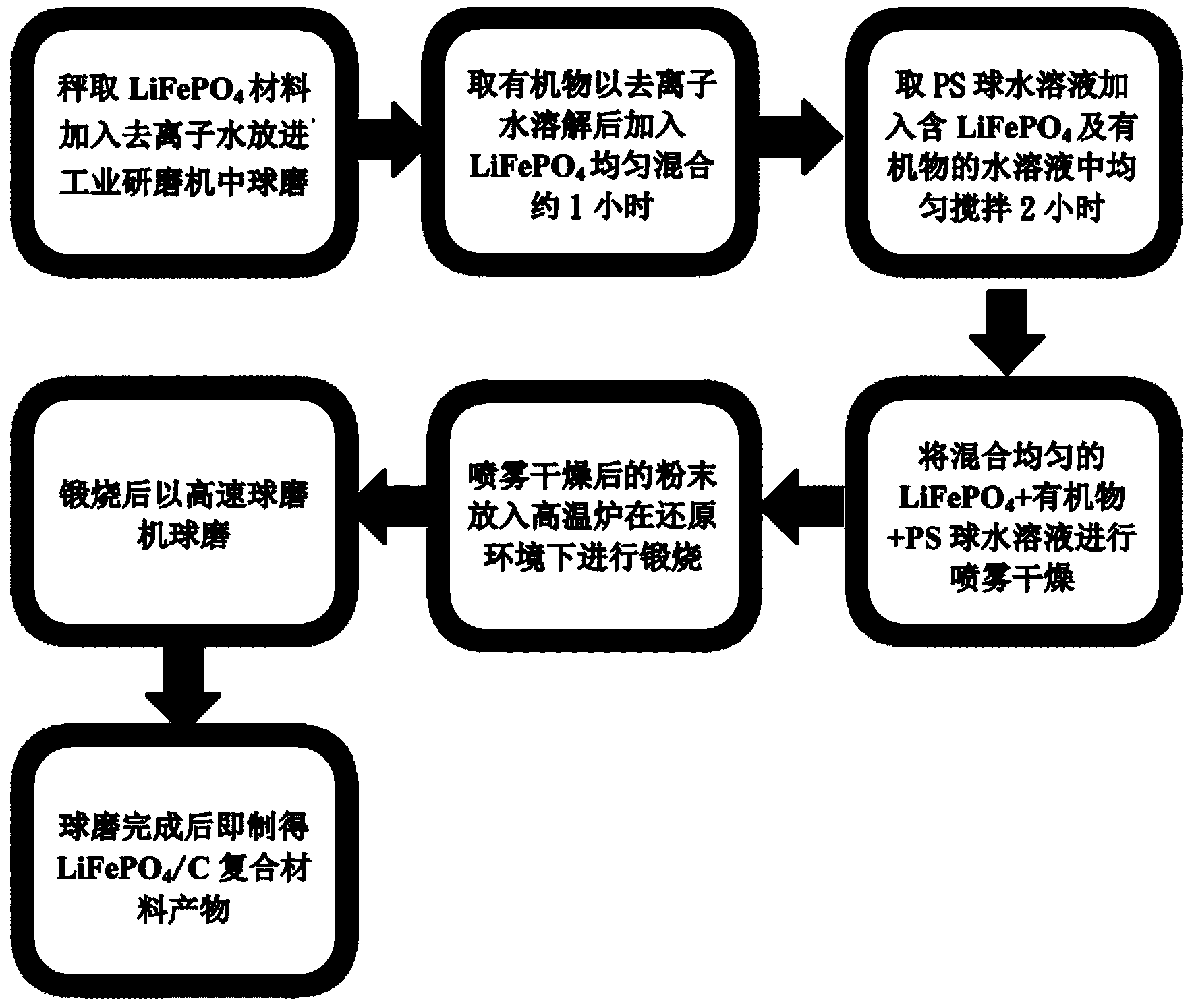

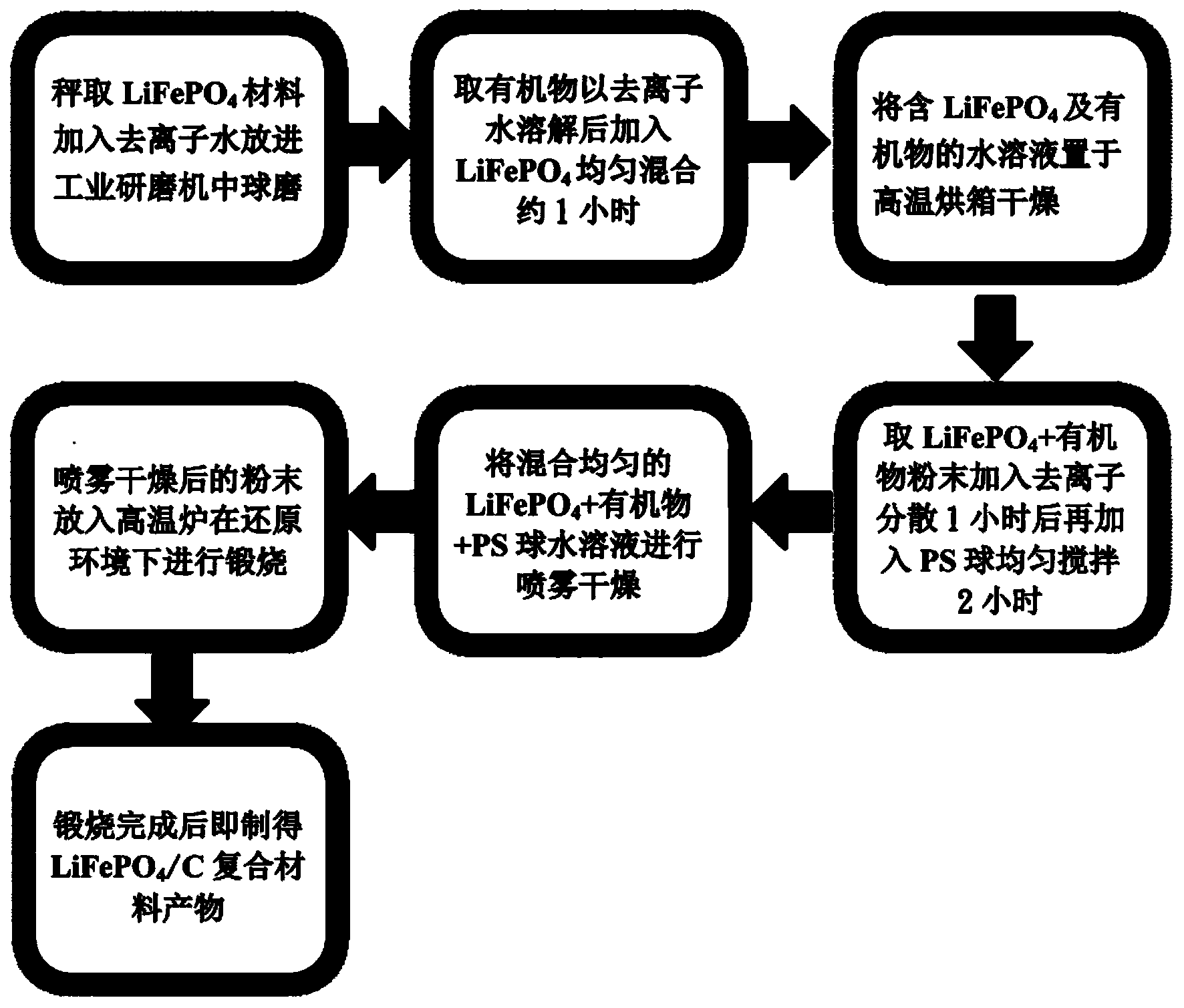

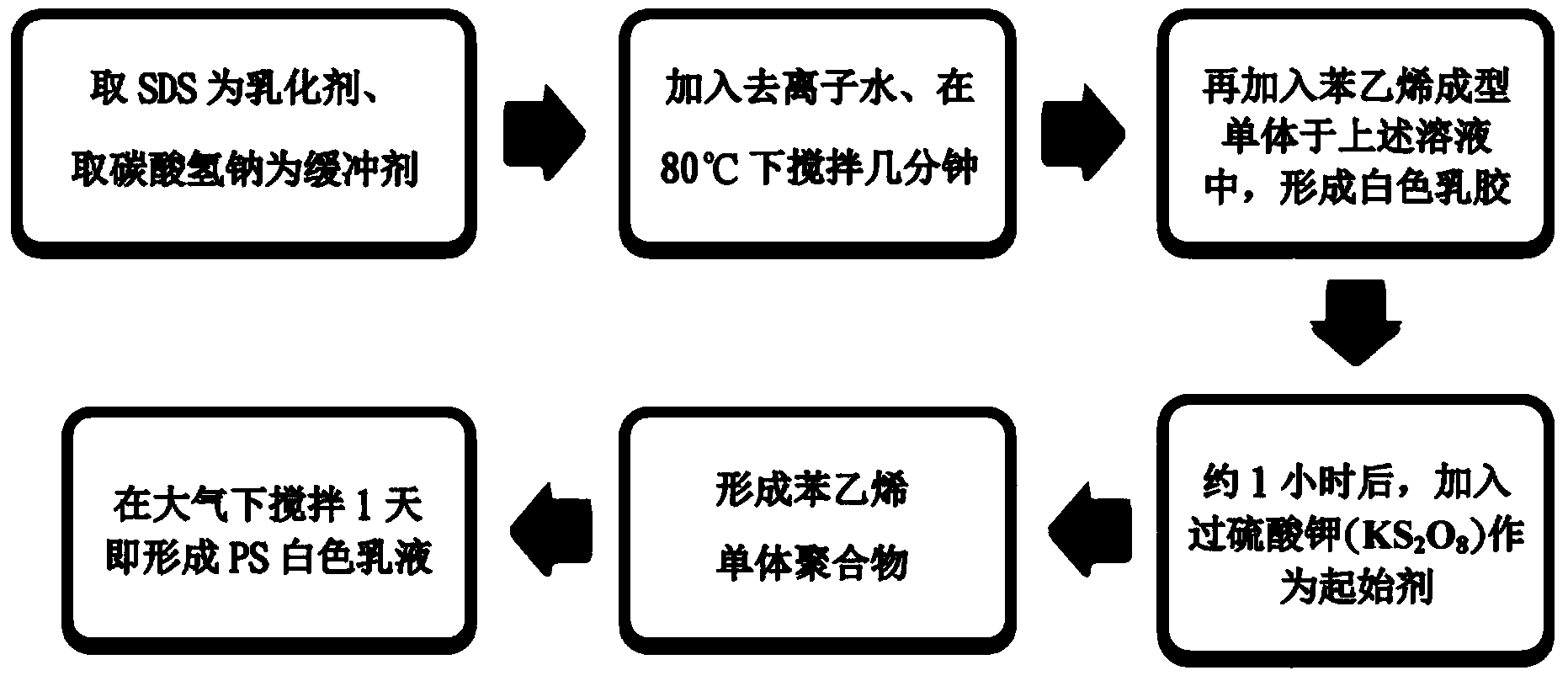

Method used

Image

Examples

Embodiment 1

[0160] A circular cathode electrode for a coin-type battery was fabricated using the LFP / C sample C, and was sealed via a battery sealing machine to fabricate a coin-type battery, respectively. The reversible oxidation / reduction electrochemical reaction CV diagram of the LFP / C circular cathode electrode was obtained by cyclic voltammetry (CV), as shown in Figure 13 Shown, and get its related CV parameter values, as shown in Table 4.

[0161] Table 4 CV parameter analysis results

[0162]

[0163] and , according to the CV parameter values in Table 4, the circular cathode electrode made of LFP / C sample C, its ΔE 1 Between 0.71 and 0.72, R 1 and R 2 Between 1.02 and 1.19, which means that the composite spherical LFP / C prepared by spray drying method has a good reversible oxidation / reduction electrochemical reaction in the potential range of 2.5-4.3V, and can also increase the battery life of the button battery. The overall stability and the ability to charge and disc...

Embodiment 2

[0165] Use LFP / C cathode material sample B to make circular cathode electrodes for button batteries, and then use a discharge analyzer to test the discharge capacity at 0.1C, 0.2C~10C charge / discharge rates. The test results are shown in Table 5 and Table 6, and the charge and discharge curves are shown in Figure 14 and Figure 15 shown.

[0166] Table 5 Gram capacity at 0.1C / 0.1C charge / discharge rate

[0167]

[0168]

[0169] Table 6 The gram capacitance at different charge / discharge rates from 0.2C to 10C

[0170]

[0171]

[0172] According to the gram capacity parameter values in Table 5 and Table 6, the button-type battery of the present embodiment uses a one-stage spray-coated carbon source to synthesize an LFP / C cathode material coated with 6wt% Glu+10wt% nano PS balls by LFP as Circular negative electrode, at 0.1C / 0.1C charge / discharge rate, its gram capacitance can reach 137mAh / g, and at 0.2C / 0.2C, 0.2C / 0.5C and 0.2C / 1C charge / discharge rate , the...

Embodiment 3

[0174] Use LFP / C cathode material sample C to make circular cathode electrodes for button batteries, and then use a discharge analyzer to test the discharge capacity at 0.1C, 0.2C~10C charge / discharge rates. The test results are shown in Table 7 and Table 8, and the charge and discharge curves are shown in Figure 16 and Figure 17 shown.

[0175] Table 7 Gram capacity at 0.1C / 0.1C charge / discharge rate

[0176]

[0177] Table 8 Capacitance in grams at different charge / discharge rates from 0.2C to 10C

[0178]

[0179]

[0180] According to the gram capacity parameter values in Table 7 and Table 8, the button-type battery of the present embodiment uses a two-stage spray-coated carbon source to synthesize LFP-coated 6wt%Glu+10wt% nano PS ball LFP / C cathode material It is a circular negative electrode, and its gram capacitance can reach 158mAh / g at 0.1C / 0.1C charge / discharge rate; at 0.2C / 0.2C, 0.2C / 0.5C, 0.2C / 1C, 0.2C / 3C And 0.2C / 5C charge / discharge rate, its gra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com