Method for arranging silicon dioxide coating on surface of solar photovoltaic back plate

A solar photovoltaic and silicon dioxide technology, applied in the field of solar photovoltaic backsheets, can solve the problems of delamination, foaming, high water vapor transmission rate of polymer films, affecting the photoelectric conversion efficiency and service life of photovoltaic modules, etc. Good protection, extended aging time, good efficiency and long-term reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

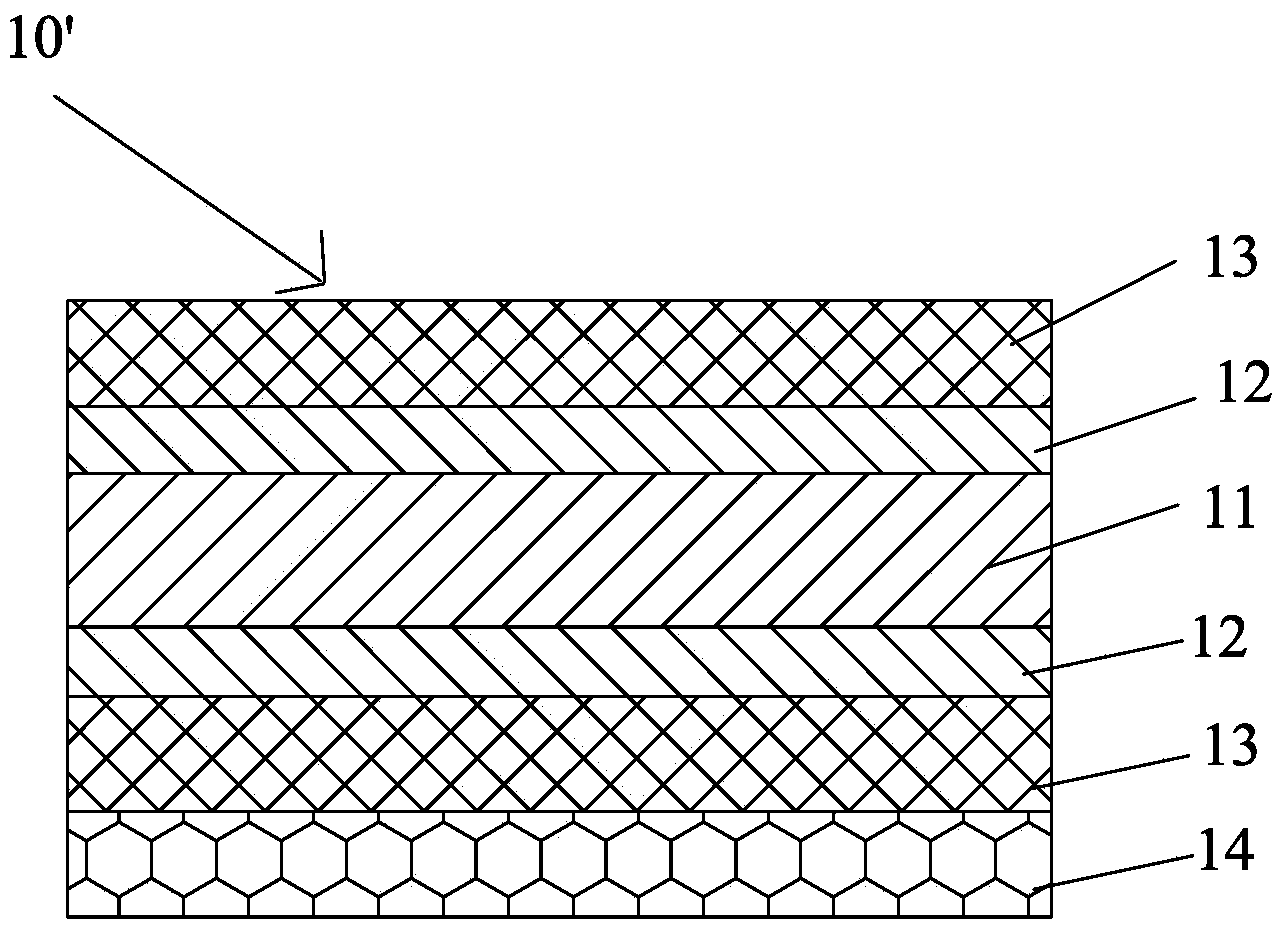

[0042] A method for arranging a silicon dioxide coating on the surface of a solar photovoltaic backplane, comprising the steps of,

[0043] The two sides of the solar photovoltaic backboard obtained in Comparative Example 1 are coated with a layer of polysilazane solution, and the dry thickness of the coating is 200 nanometers; then, the relative humidity is 85%, and the temperature is 85° C. in an oven for 2-3 hours; then Baking at a temperature of 120-150° C. for 1-2 hours, thereby converting the polysilazane solution into a silicon dioxide coating, and obtaining a solar photovoltaic backplane with a silicon dioxide coating.

Embodiment 2

[0045] A method for arranging a silicon dioxide coating on the surface of a solar photovoltaic backplane, comprising the steps of,

[0046] 1) Configure adhesive glue;

[0047] 2) PET film gluing: take 250 micron PET film, coat the above-mentioned adhesive glue on one side of the PET film, drive off the solvent, dry, and the dry thickness of the coating layer is 10 microns; then the PET film glued surface is combined with the fluorine film Rolling, rolling temperature 80-120°C, pressure 0.1-2MPa; Then, coat the above-mentioned adhesive glue on the other side of the PET film, drive off the solvent, dry, and the dry thickness of the coating layer is 10 microns; then coat the PET film The rubber surface and the fluorine film are compositely rolled, and the rolling temperature is 80-120°C, and the pressure is 0.1-2MPa to obtain a glass film-based backplane;

[0048] 3) curing the glass film-based backsheet obtained in step 2) at 60-100° C. for 6-10 hours to obtain a solar photovolt...

Embodiment 3

[0051] A method for arranging a silicon dioxide coating on the surface of a solar photovoltaic backplane, comprising the steps of,

[0052] 1) Configure adhesive glue;

[0053] 2) PET film gluing: take 250 micron PET film, coat the above-mentioned adhesive glue on one side of the PET film, drive away the solvent, dry, and the dry thickness of the coating layer is 10 microns; then the PET film gluing surface is compounded with the fluorine film Rolling, rolling temperature 80-120 ℃, pressure 0.1-2MPa; Then, coat the above-mentioned adhesive glue on the other side of the PET film, drive off the solvent, dry, and the dry thickness of the coating layer is 10 microns; then coat the PET film The rubber surface and the fluorine film are compositely rolled, and the rolling temperature is 80-120°C, and the pressure is 0.1-2MPa to obtain a glass film-based backplane;

[0054] 3) curing the glass film-based backsheet obtained in step 2) at 60-100° C. for 6-10 hours to obtain a solar pho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com