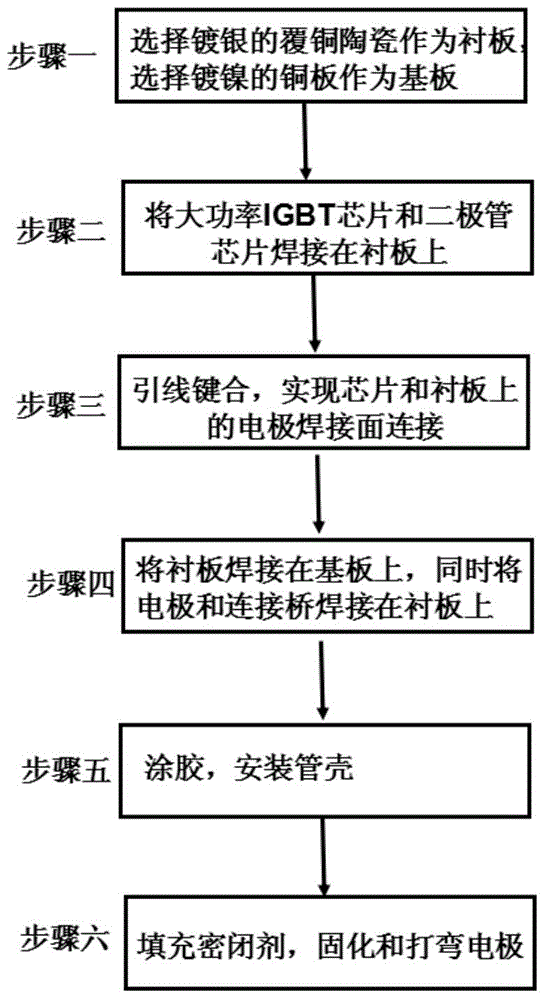

Method for encapsulating high-power IGBT device through performing non-pressure low-temperature sintering on nano silver soldering paste

A low-temperature sintering and nano-silver technology, which is applied in the manufacture of electrical solid devices, semiconductor devices, semiconductor/solid devices, etc., can solve problems such as low porosity, improve performance, simplify packaging process, improve work efficiency and service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0029] Example 1: First, ultrasonic and plasma are used to clean impurities on the surface of the liner and substrate. A cross-shaped solder paste is then printed on the solder side of the backing board. When the cross-shaped coverage area accounts for 30% of the total area of the connection layer, paste the chip and make the nano-silver solder paste fully wet the chip until the solder paste spreads evenly around the chip. At this time, the thickness of the connection layer is 30% of the thickness of the screen printing solder paste layer. Then carry out sintering: from normal temperature to 250°C-270°C, and then keep warm for 10min-30min, the heating rate is 3-5°C / min. After sintering, the porosity is lower than 1%.

example 2

[0030] Example 2: First, ultrasonic and plasma are used to clean impurities on the surface of the liner and substrate. A cross-shaped solder paste is then printed on the solder side of the backing board. When the cross-shaped coverage area accounts for 50% of the total area of the connection layer, paste the chip and make the nano-silver solder paste fully wet the chip until the solder paste spreads evenly around the chip. At this time, the thickness of the connection layer is 50% of the thickness of the screen printing solder paste layer. Then sintering: from normal temperature to 250°C, and then keep the temperature for 30 minutes, the heating rate is 5°C / min. After sintering, the porosity is between 1% and 1.5%.

example 3

[0031] Example 3: First, ultrasonic and plasma are used to clean impurities on the surface of the liner and substrate. A cross-shaped solder paste is then printed on the solder side of the backing board. When the cross-shaped coverage area accounts for 70% of the total area of the connection layer, paste the chip and make the nano-silver solder paste fully wet the chip until the solder paste spreads evenly around the chip. At this time, the thickness of the connecting layer is 70% of the thickness of the screen printing solder paste layer. Then sintering: from normal temperature to 250°C, and then keep the temperature for 30 minutes, the heating rate is 5°C / min. After sintering, the porosity is between 1.5% and 2%.

[0032] The packaging scheme of the present invention is easy to operate, has good thermal cycle capability and thermal fatigue resistance, and at the same time has excellent electrical connection performance, and has extremely high popularization value.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| sintering temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com