Brass-wind instrument piston and manufacturing method thereof

A production method and piston technology, applied to musical instruments, wind instruments, instruments, etc., can solve the problems of piston key damage, high scrap rate, and damage to brass instruments, and achieve high installation concentricity, high product qualification rate, and easy The effect of corrosion damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in the form of examples, and the implementation details of the present invention will be given, but it should not be considered as a limitation of the present invention.

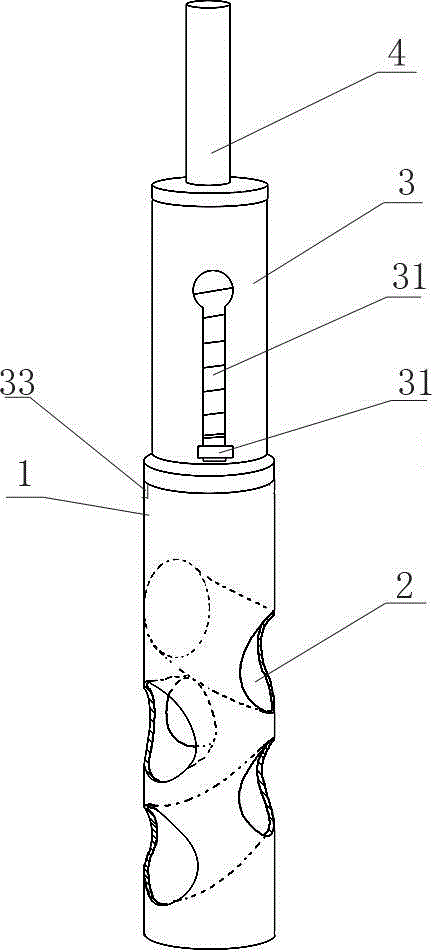

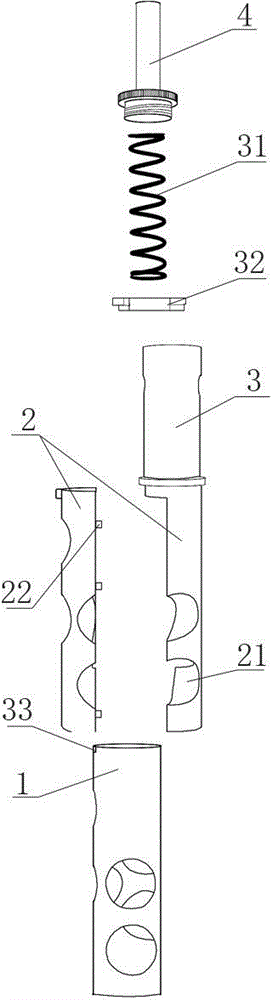

[0030] Please refer to figure 1 and figure 2 As shown, the present invention provides a brass instrument piston, which is composed of a piston outer body 1, a piston core 2 located inside the piston outer body, and a spring tube 3 located at the upper end of the piston core. The piston outer body is made of metal cylinder, the piston core 2 and the spring tube 3 are made of plastic, the piston core is a plastic cylinder, the plastic cylinder of the piston core is provided with a plurality of vent holes 21 that are not connected to each other, and the plastic cylinder is divided from the middle It is two parts cut longitudinally, and a plurality of assembly positioning pins 22 are arranged between the two parts of the semi-cylindrica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com